Composition heating type vegetable dewatering device

A vegetable dehydration and heating device technology, which is applied in the direction of preserving fruits/vegetables through dehydration, can solve the problems of slow drying speed, achieve fast drying speed, improve practicability, and reduce radiation temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

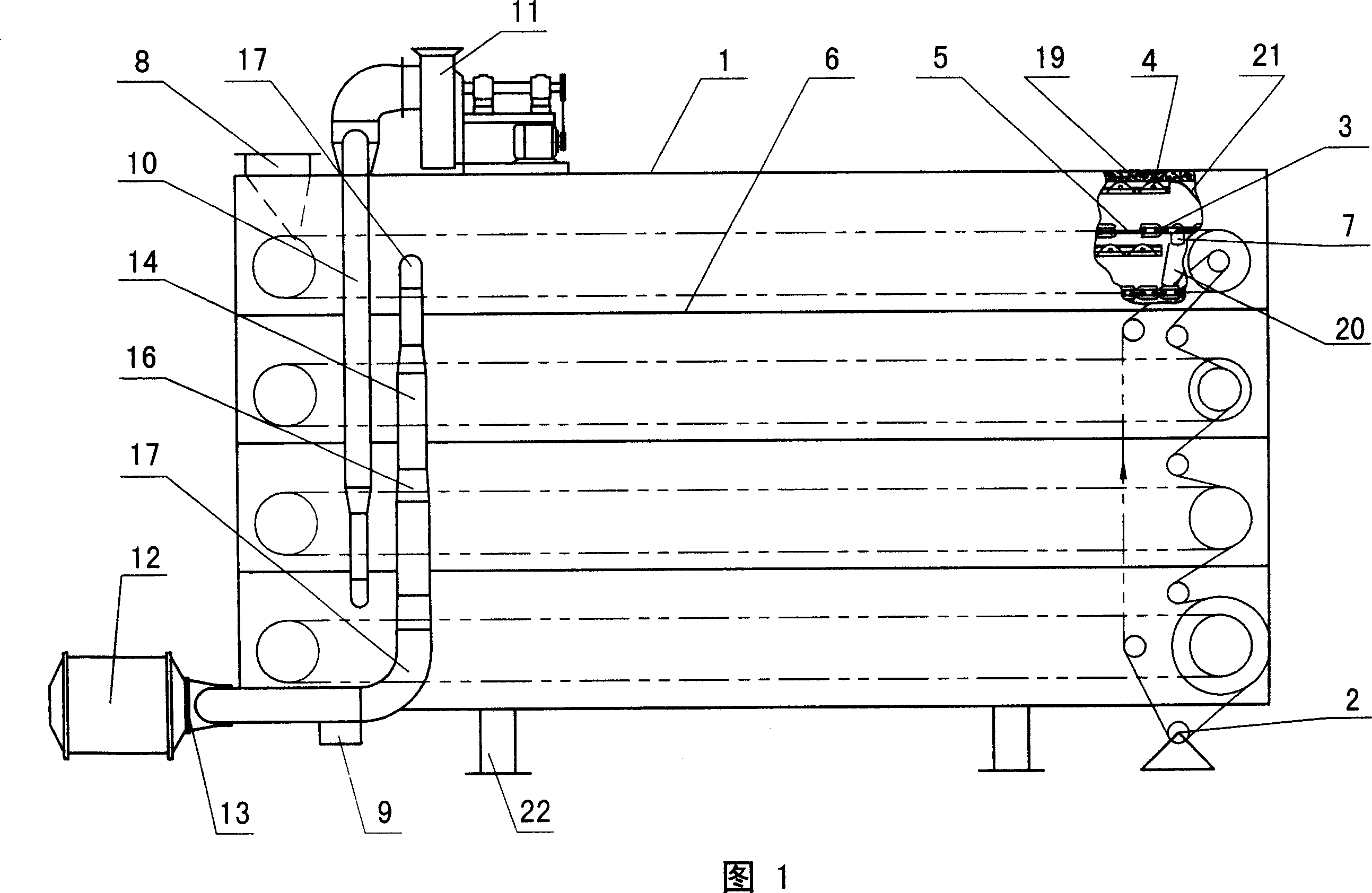

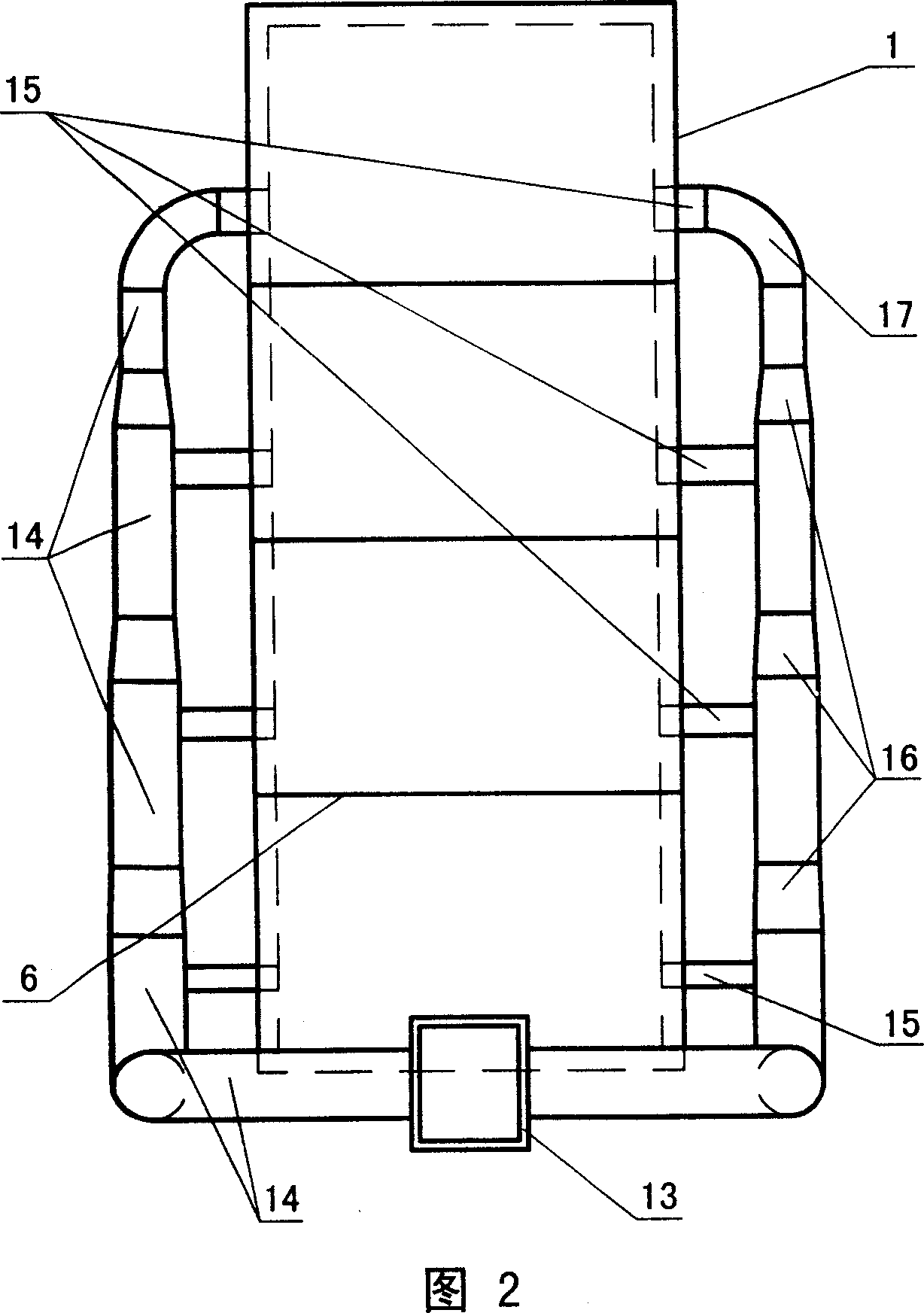

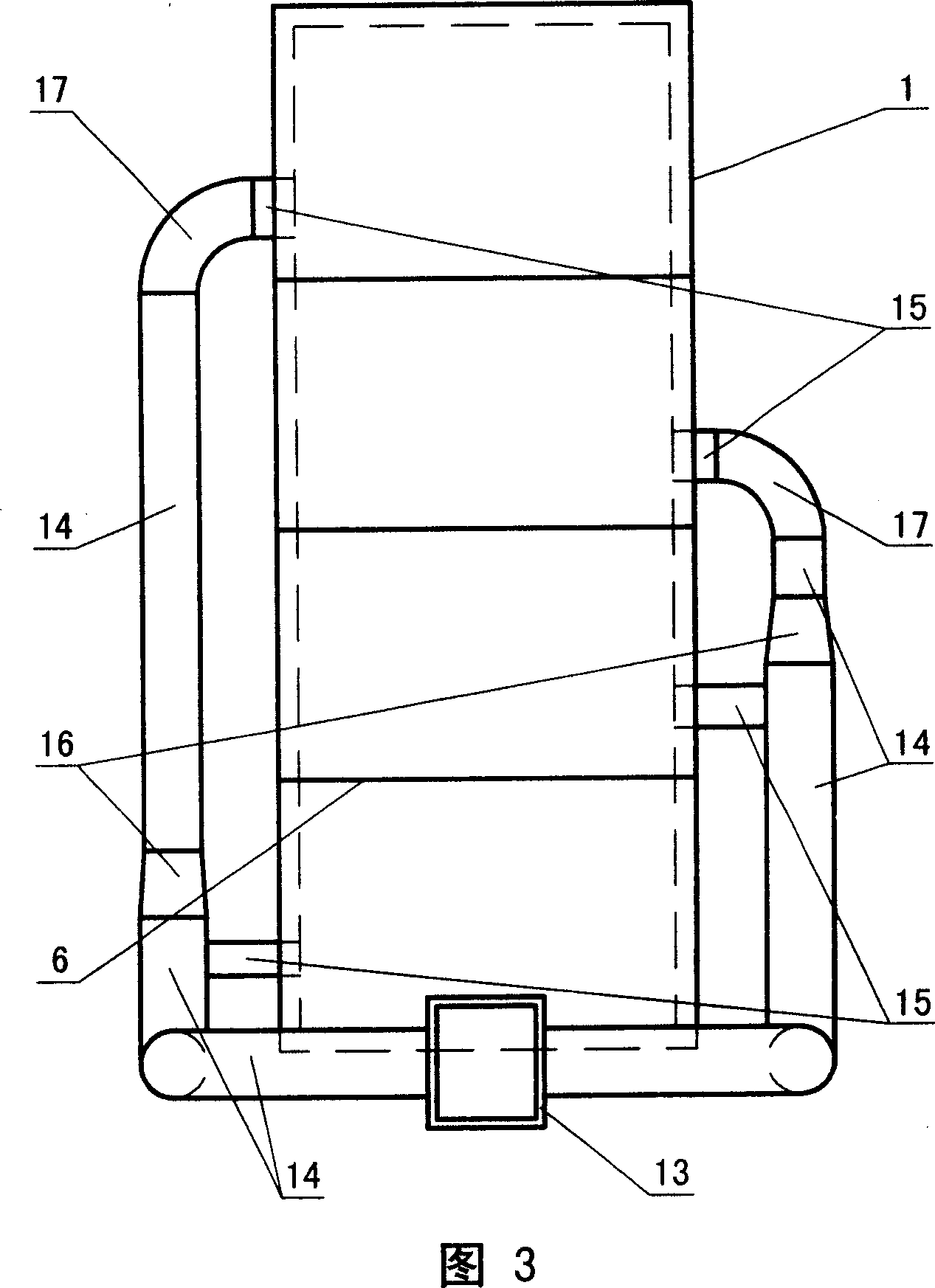

[0025] specific implementation plan

[0026] 1. Drying box 2, transmission device 3, conveying device 4, radiation device 5, guide rail 6, partition plate 7, conveying chain plate 8, material inlet 9, material outlet 10, air duct 11, fan 12, heating Device 13, flange 14, straight pipe 15, connecting pipe 16, reducing pipe 17, elbow 18, connecting pipe flange 19, insulation layer 20, material guide groove 21, deflector 22, bracket

[0027] In the embodiment shown in Fig. 1, Fig. 2, Fig. 4: the top of drying box body 1 is provided with feed inlet 8, and the bottom is provided with discharge port 9, and in drying box body 1, divides into many by dividing plate 6 horizontally. Each layer is equipped with a set of conveying device 3 driven by the transmission device 2, and the conveying chain plate 7 of the conveying device 3 is supported on the guide rail 5 to form a trough-shaped material channel; At the end, a deflector 21 is arranged above it to ensure that the air in the dryi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com