Metal foil band electroplating system and application thereof

A technology of metal foil strips and electroplating tanks, applied in the direction of electrolysis process, electrolysis components, etc., can solve the problems of current collectors losing electrical contact, long preparation time period, complicated operation, etc., and achieve fast production speed, low cost and simple operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with drawings and embodiments.

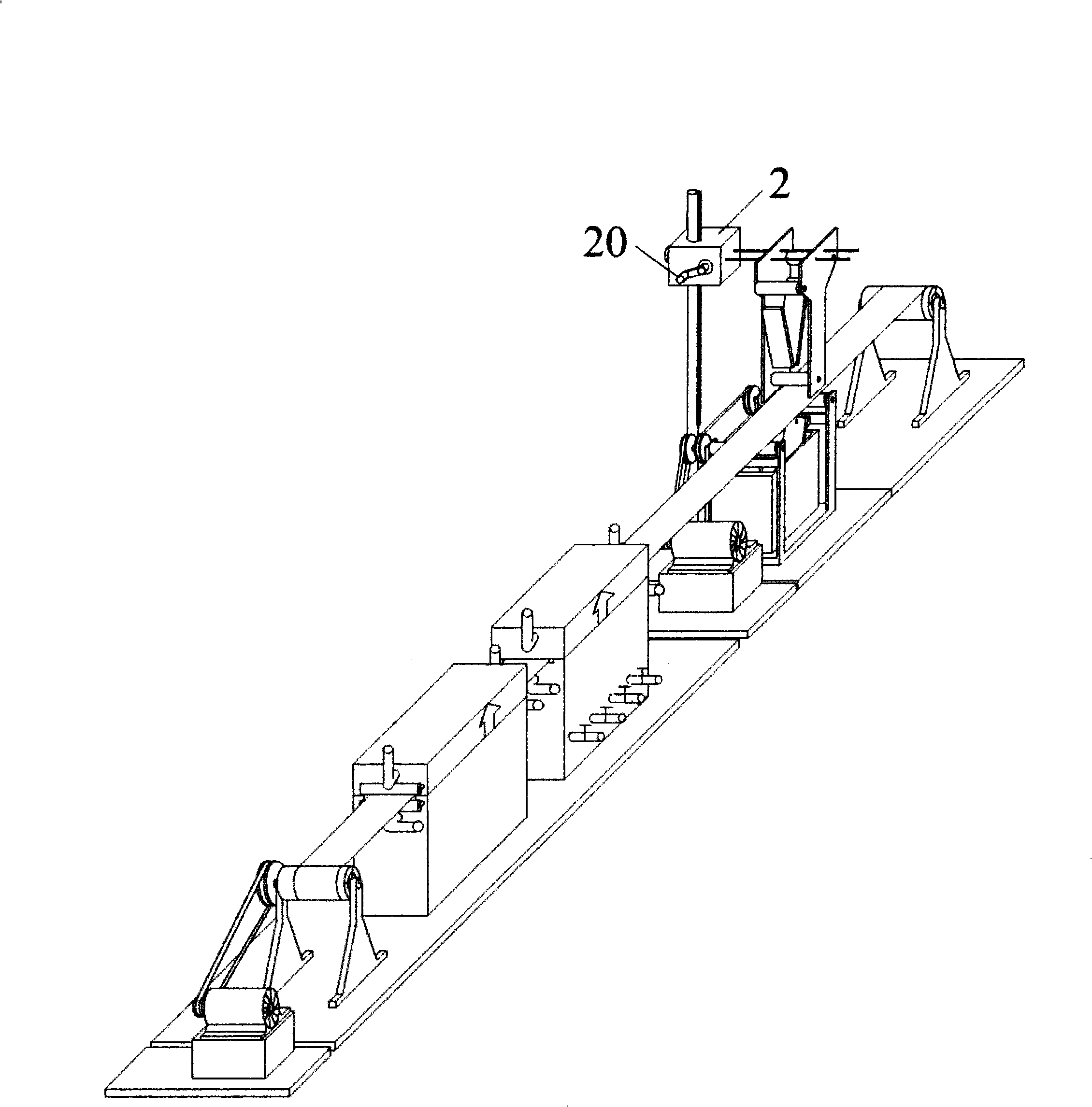

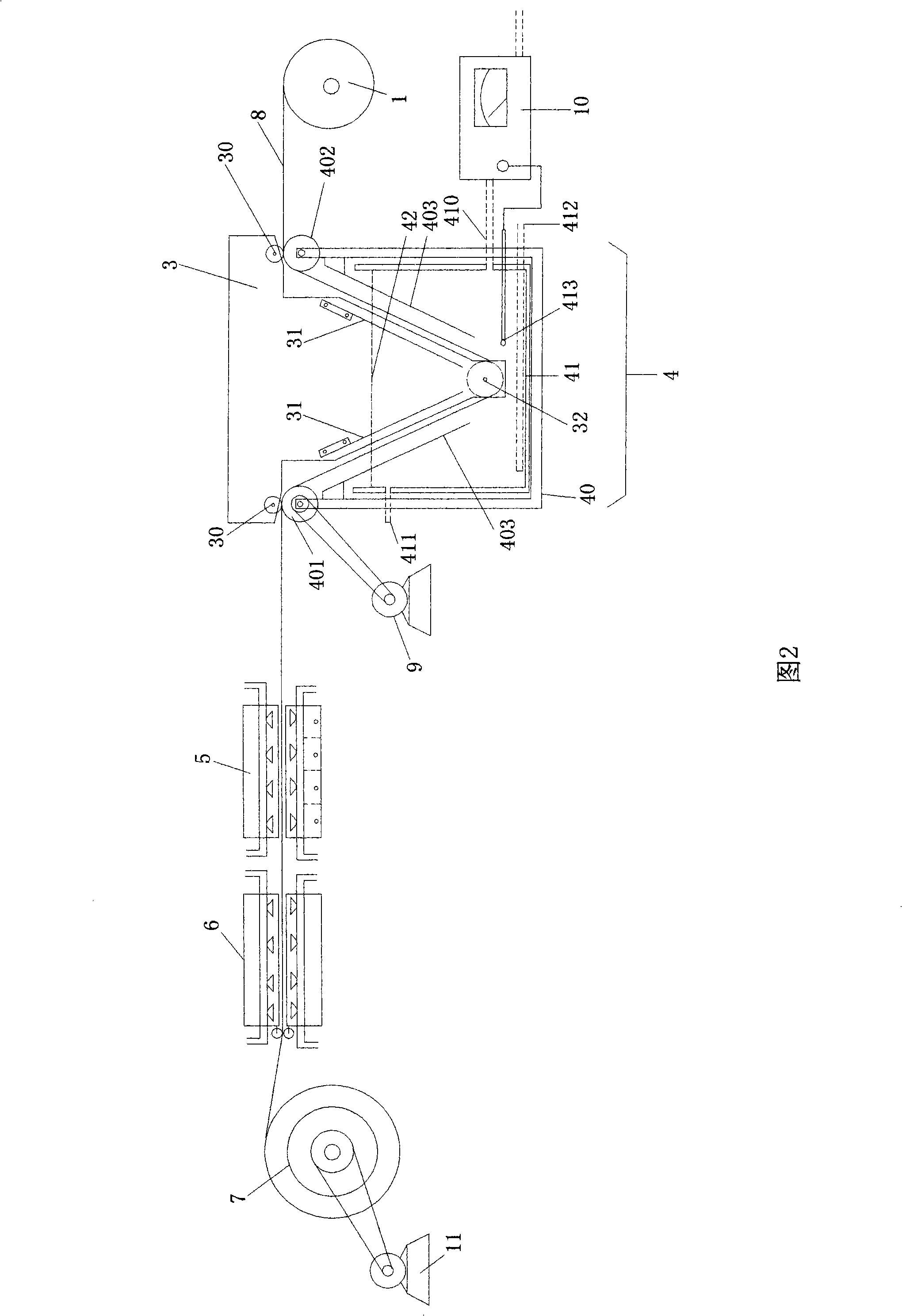

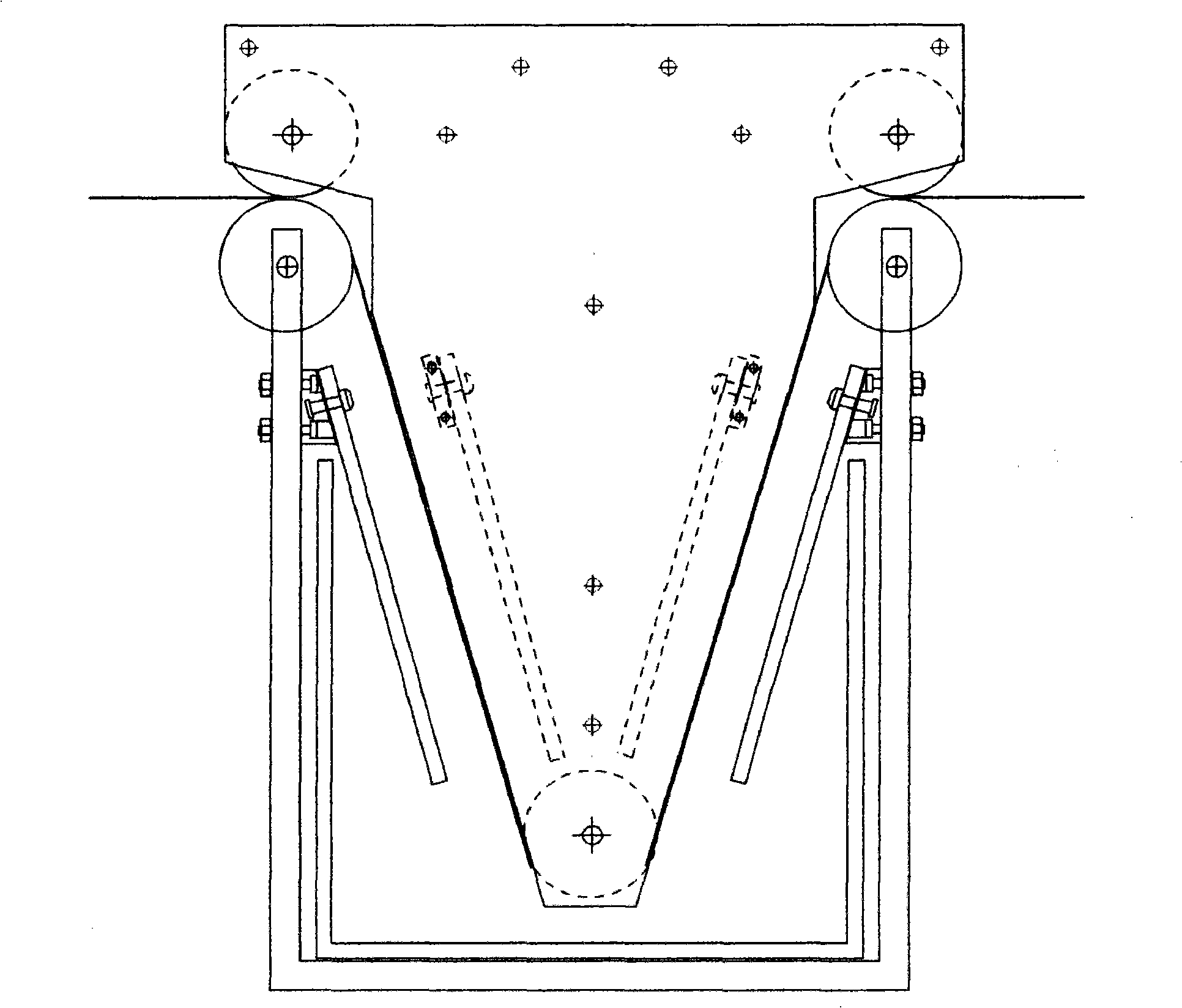

[0028] Such as figure 1 , Figure 2 and image 3 A metal foil strip electroplating system shown includes an unwinder 1, a plating head elevator 2, a plating head 3, an electroplating tank 4, a washing box 5, a blast drying oven 6 and a winder 7, and the metal foil strip 8. One end is connected to the unwinding machine 1, and the other end is connected to the winding machine 7. In the direction in which the metal foil strip 8 advances, an electroplating tank 4, a washing box 5, and a blast drying box 6 are arranged in sequence, and a plating head lifter 2 The plating head 3 is connected, and the plating head 3 is arranged above the electroplating tank 4 . Plating head elevator 2 is provided with the manual handle 20 that regulates plating head 3 heights. The winder 7 is connected to a force induction motor 11. When the metal foil strip 8 is stretched, it is controlled ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com