Efficient separation device and method for ocean microplastics

A separation method and microplastic technology, applied in wet separation, solid separation, measurement devices, etc., can solve the problems of high economic cost, no distinction, and large manual intervention.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] High-efficiency separation device for marine microplastics, including: electric heating constant temperature blast drying oven, heat collecting magnetic stirrer, electronic balance, numerical control ultrasonic cleaner, stereo microscope, Fourier transform infrared spectrometer, microscope system and ultrapure water treatment system, The ultrapure water treatment system is used to flush the filtered filter and the salt on the filter membrane, the microplastics are placed in the numerically controlled ultrasonic cleaner, the electric heating constant temperature blast drying box and the heat collecting type magnetic stirrer Connection, used for the concentration of the microplastic flotation liquid, the separated solution is analyzed by a Fourier transform infrared spectrometer, and the microplastics are analyzed by a solid electronic balance, a stereo microscope and a microscope system to form a microplastic recycling rate data.

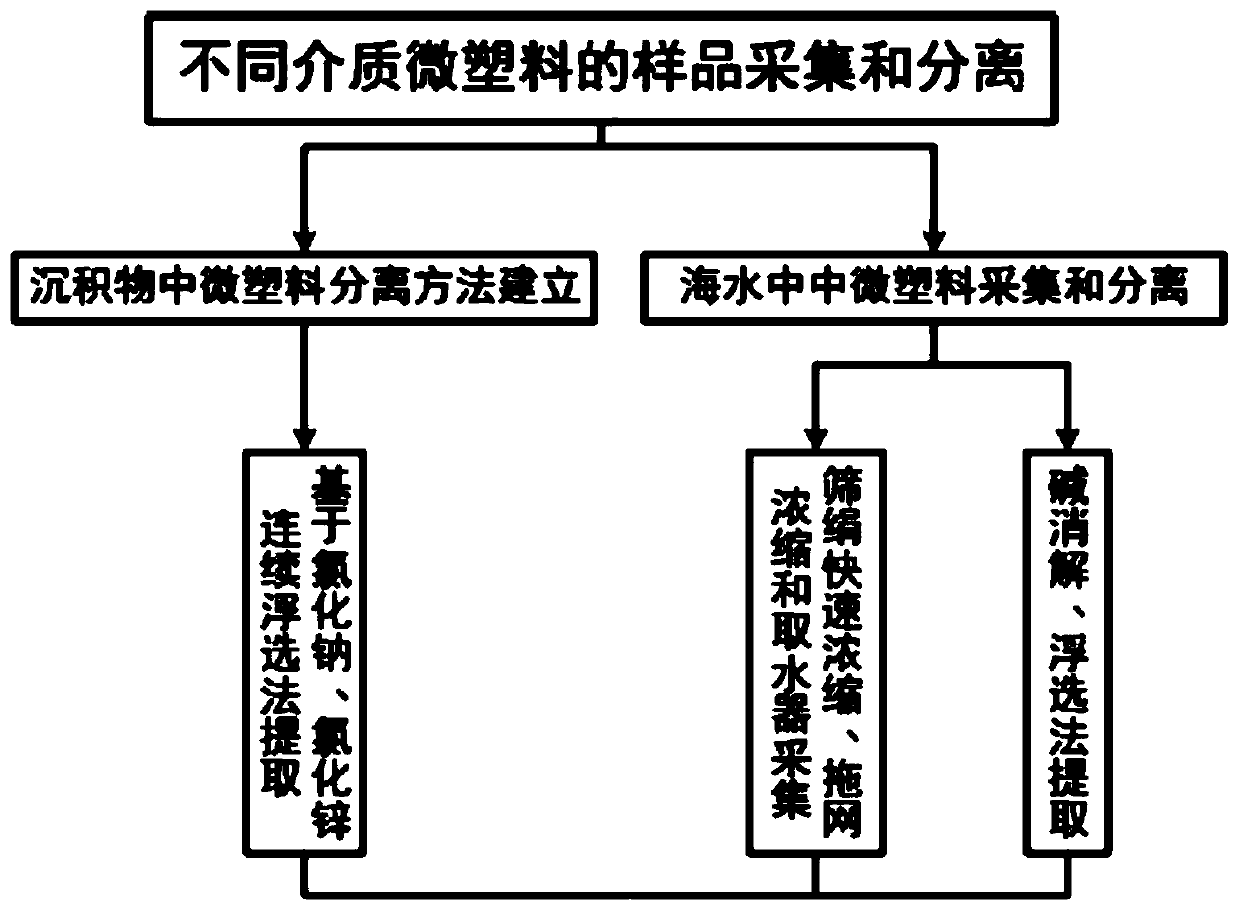

[0031] see figure 1 , an efficient sep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com