Drying, distillation device of aromatic plant and its method

A distillation device and aromatic plant technology, applied in the direction of essential oils/fragrances, fat production, etc., can solve the problems of waste of resources, reduce economic benefits, etc., and achieve the effect of improving economic benefits and saving aromatic plant resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

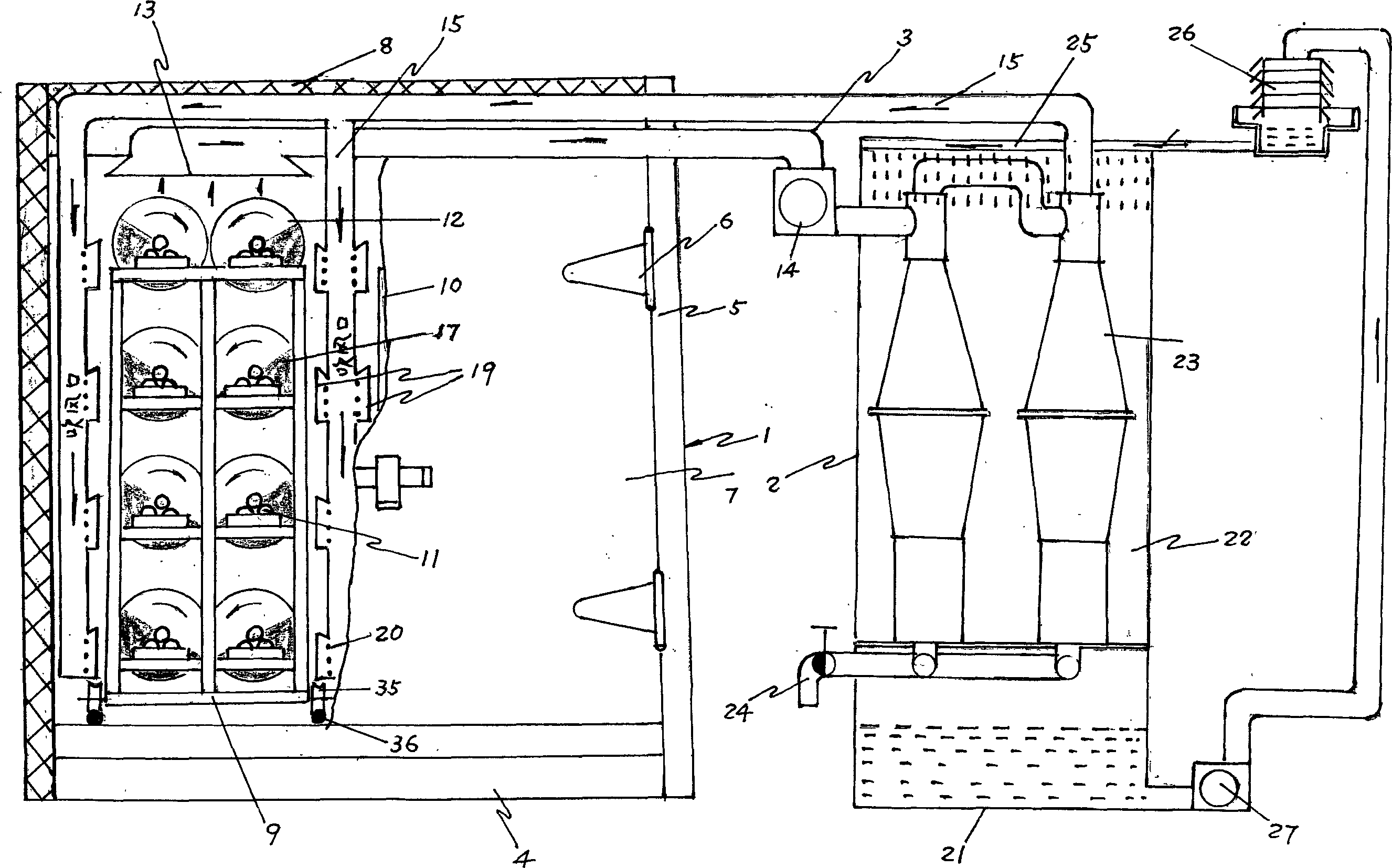

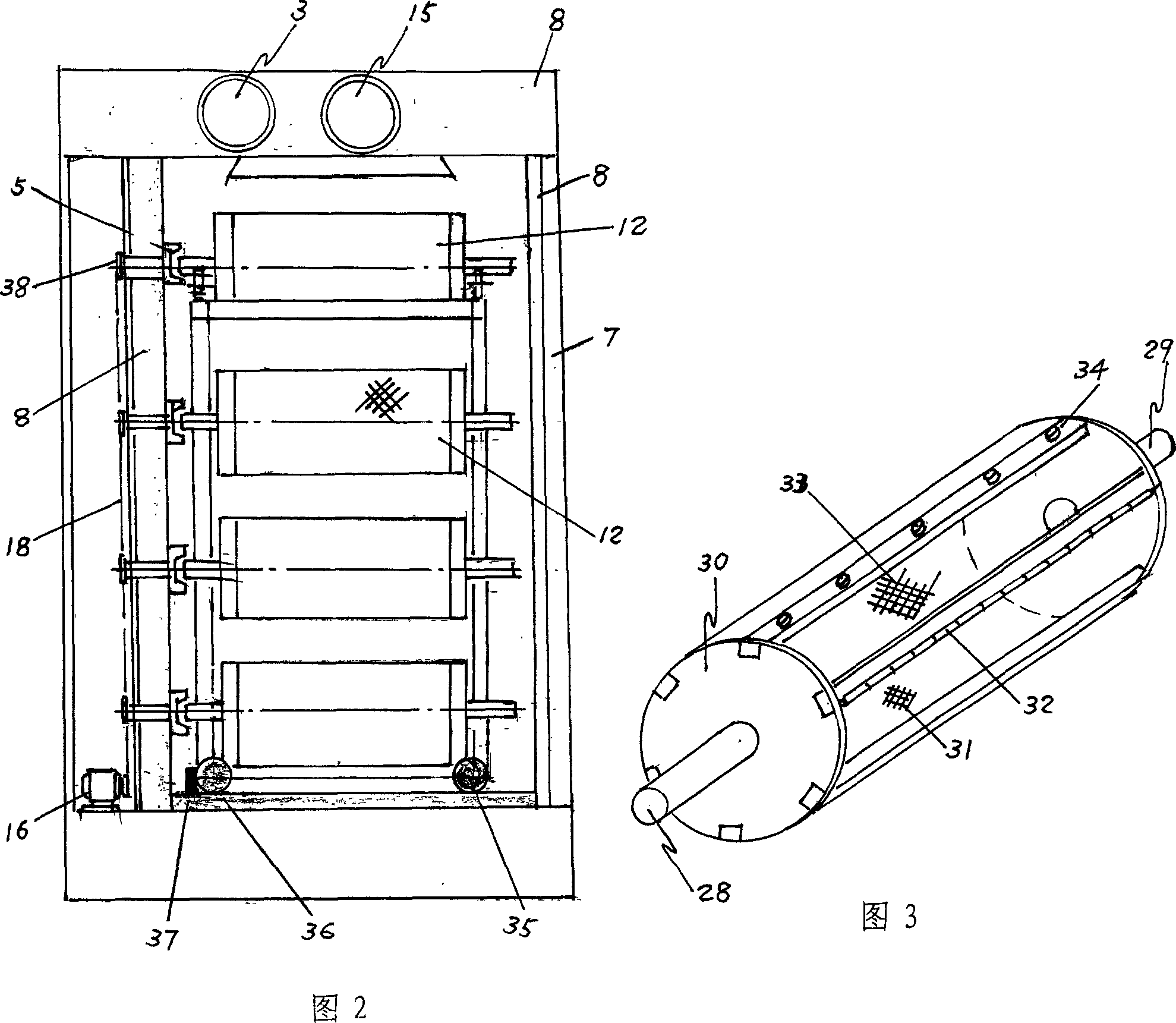

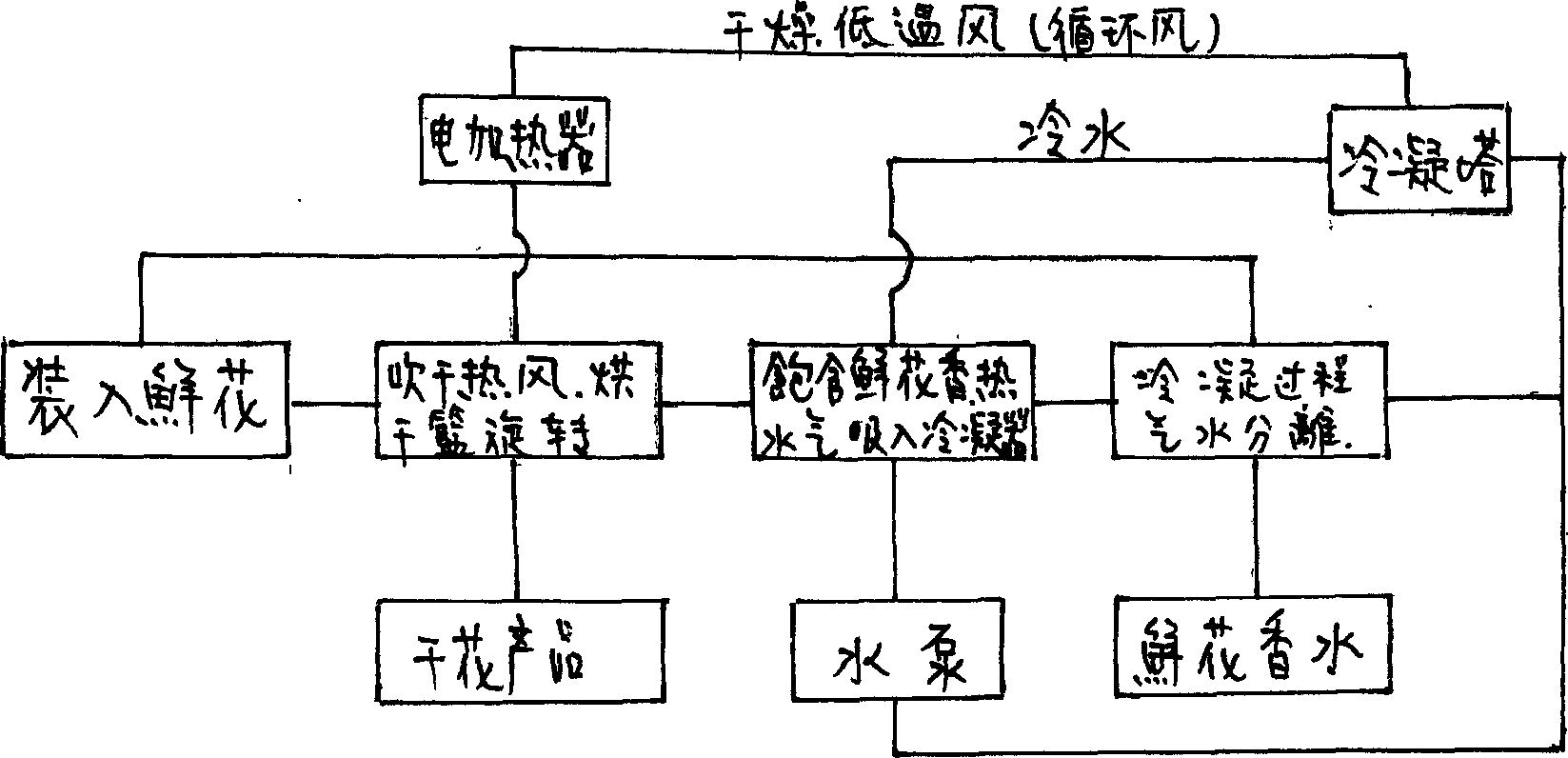

[0019] Example 1. A device for drying and distilling aromatic plants, such as Figure 1 to Figure 4 shown. It includes a drying box 1, a distillation condensing box 2 and a steam return pipe 3 connecting them. The drying box 1 includes a base 4, a box body 5 fixed on the base 4, a box door 7 mounted on the box body 5 with a hinge 6, an insulation layer 8 coated on the outside of the box body 5, and symmetrically fixed on the box body 5. The left front and rear base frames 9 and the right front and rear base frames 10 in the interior, the front and rear bearing frames 11 composed of two rollers installed on the left and right side base frames 9 and 10, are installed on each group of front and rear bearing frames 11 respectively. The rotary drying cage 12 in the middle, the steam return air 13 installed on the top of the cabinet 5 and above the rotary drying cage 12, the steam return air 13 fixed between the cabinet 5 and the distillation condensing box 2 and the inlet communi...

Embodiment 2

[0025] Example 2. A method for aromatic plants. The air inlet temperature at the outlet of the air inlet pipe is 80-90°C, the rotating speed of the rotary drying cage is 20-50 rpm, and the water temperature of the spray tank is 10-50°C.

[0026] The test proves that the drying efficiency is the highest when the air inlet temperature is 80-90°C and the rotating speed of the rotary drying cage is 20-50 rpm. When the water temperature in the spray tank is 10-50°C, the distillation efficiency is the highest.

[0027] The devices and methods of Examples 1-2 can recover a large amount of aromatic substances contained in water and distill natural perfume or oil while drying aromatic plants and producing dry products. Not only can save precious aromatic plant resources, but also can greatly improve economic benefits. It can be widely used in the processing and production of roses, jasmine products and other aromatic plant products.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com