Movable multi-use drying machine

A dryer and mobile technology, applied in the field of mobile multi-purpose dryers, can solve the problems of high energy consumption, time-consuming, labor-intensive efficiency, and reduced quality, and achieve the effect of good quality, high efficiency, and rapid drying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

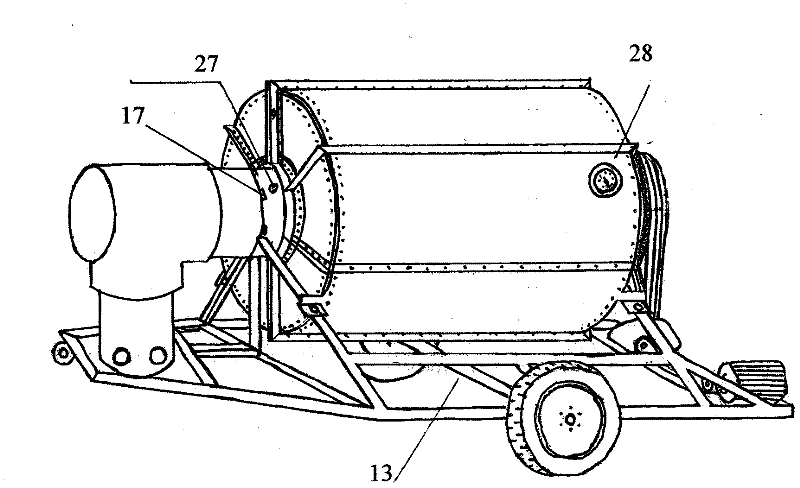

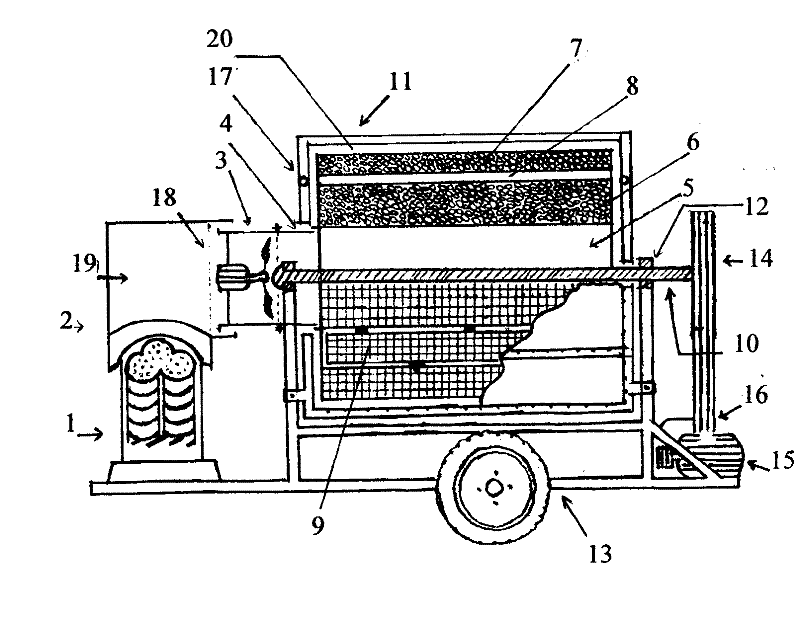

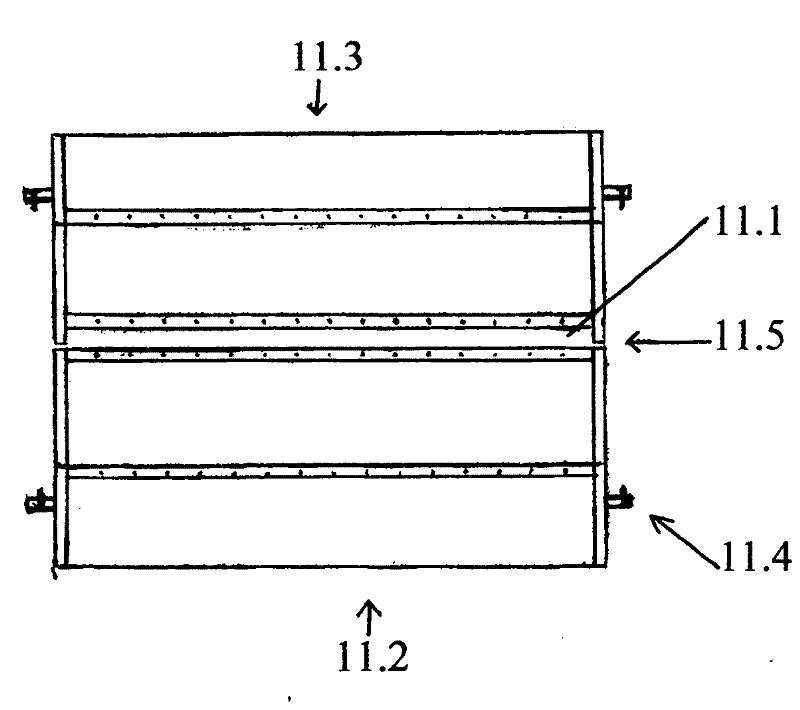

[0017] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0018] Embodiments of the present invention refer to figure 1 , 2 , 3, 4, 5, and 6.

[0019] The first embodiment is a mobile multi-purpose dryer, which includes three parts: a heating part, a main part, and a transmission part. Air port, main air passage, inner drying box, outer drying box and heat preservation cover, the transmission part includes main shaft, bearing, chassis frame, large pulley, motor and reducer, it is characterized in that: the hot air cover is arranged on Above the briquette furnace, the axial flow fan is installed at the air inlet, the main air passage is outside the main shaft and inside the inner drying box, and the inner drying box is wrapped outside the main air passage An annular hollow cylinder, the outside of the inner drying box is the outer drying box and the heat preservation cover in turn, and the inner drying box, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com