Preparation method of hydroxylapatite nano fibers or nano wires

A technology of hydroxyapatite and nanofibers, applied in nanostructure manufacturing, nanotechnology, nanotechnology, etc., can solve the problems of small specific surface area, reduced content of effective calcium components, poor biological activity, etc., and achieve uniform particle size, The effect of single shape and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] At 20°C, add a certain amount of 0.2g disodium hydrogen phosphate into a two-neck round bottom flask, add 5mL 2mol·L -1 Sodium hydroxide aqueous solution, mechanically stirred for 20 minutes, added 20 mL of oleic acid ethanol mixture with a volume ratio of 1:1, continued to stir for three hours, then transferred to a hydrothermal kettle, and placed in an infrared incubator at 100°C for 5 hours. The white product in the above-mentioned hydrothermal kettle was taken out, washed 3 times with distilled water and 3 times with ethanol, centrifuged to remove the reaction residue and impurities, and finally put the white powder product in a drying oven at 75°C for 8 hours.

Embodiment 2

[0020] At 30°C, add a certain amount of 0.4g disodium hydrogen phosphate into a two-neck round bottom flask, add 8mL 2mol L -1 Sodium hydroxide aqueous solution, mechanically stirred for 20 minutes, added 20 mL of oleic acid ethanol mixture with a volume ratio of 1:1, continued to stir for three hours, then transferred to a hydrothermal kettle, and placed in an infrared incubator at 120°C for 8 hours. The white product in the above-mentioned hydrothermal kettle was taken out, washed 3 times with distilled water and 3 times with ethanol, centrifuged to remove the reaction residue and impurities, and finally put the white powder product in a drying oven at 75°C for 8 hours.

Embodiment 3

[0022] At 40°C, add a certain amount of 0.5g disodium hydrogen phosphate into a two-neck round bottom flask, add 10mL 2mol L -1 Sodium hydroxide aqueous solution, mechanically stirred for 20 minutes, added 20 mL of oleic acid ethanol mixture with a volume ratio of 1:1, continued to stir for three hours, then transferred to a hydrothermal kettle, and placed in an infrared incubator at 180°C for 10 hours. The white product in the above-mentioned hydrothermal kettle was taken out, washed 3 times with distilled water and 3 times with ethanol, centrifuged to remove the reaction residue and impurities, and finally put the white powder product in a drying oven at 75°C for 8 hours.

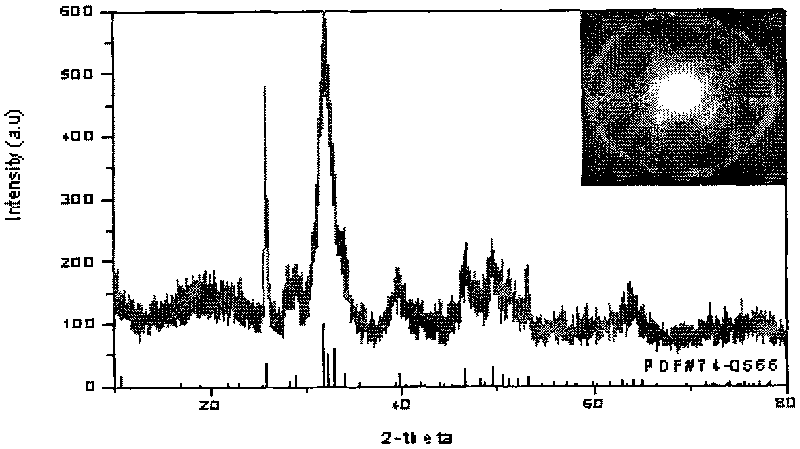

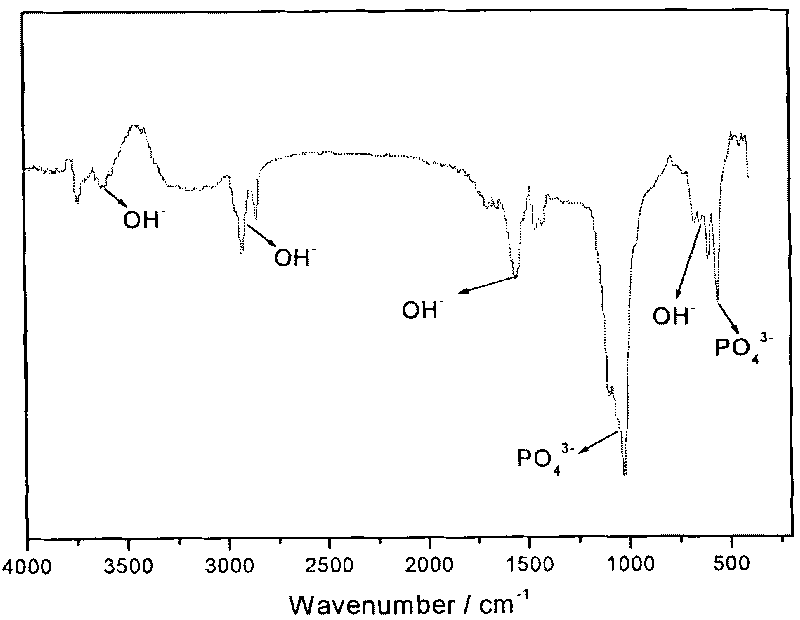

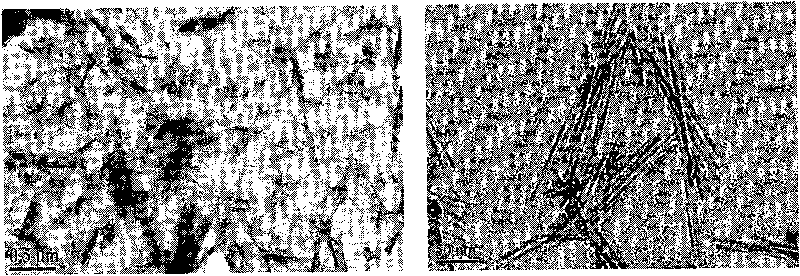

[0023] The X-ray diffraction figure of above-mentioned embodiment 1-3 gained product is as figure 1 As shown in the figure, the synthesized sample is hydroxyapatite, and the corresponding standard card is PDF#74-0566, Ca 10 (PO 4 ) 6 (OH) 2 , hexagonal system, space group P63 / m[176], unit cell paramet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com