Perovskite Co-based composite negative electrode material as well as preparation and application thereof

A composite cathode and perovskite-type technology, applied in battery electrodes, solid electrolyte fuel cells, electrical components, etc., can solve the problems of low thermal expansion coefficient of cathode materials, inconsistent thermal matching of base electrolyte, high thermal expansion coefficient, etc., and achieve high output Effects of power, excellent electrochemical performance, and catalytic activity at high and medium temperatures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

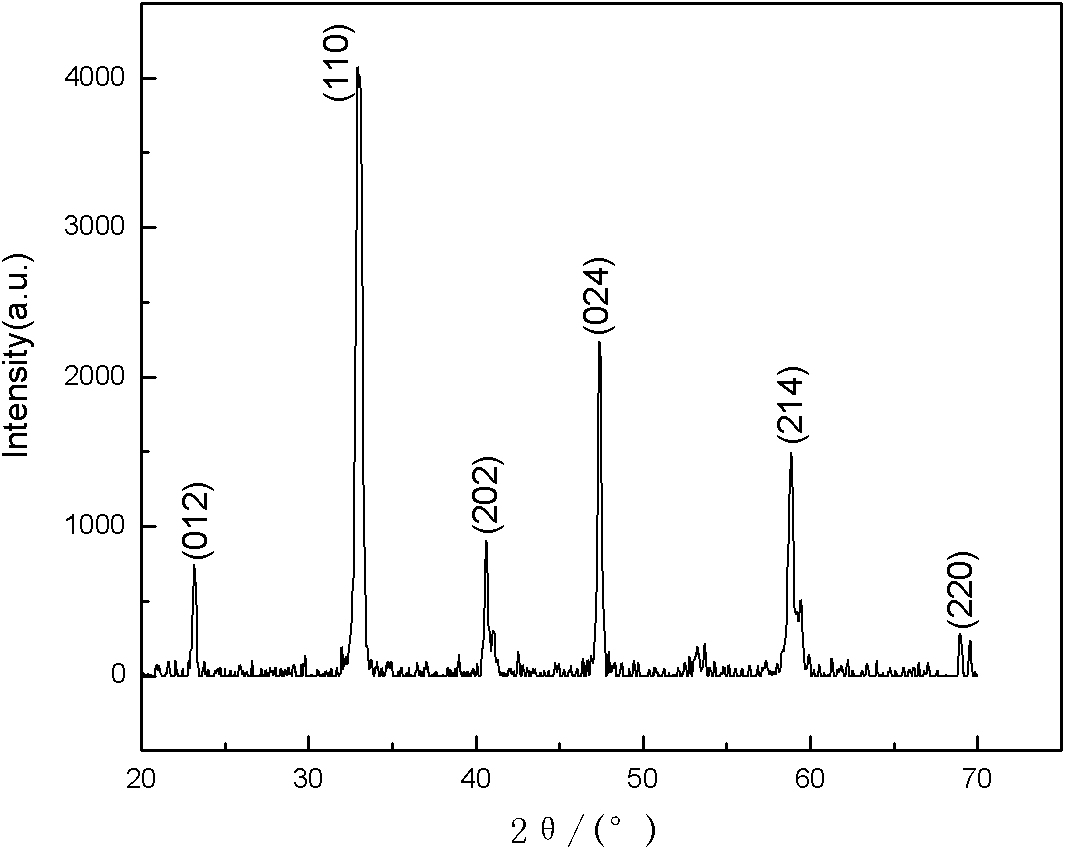

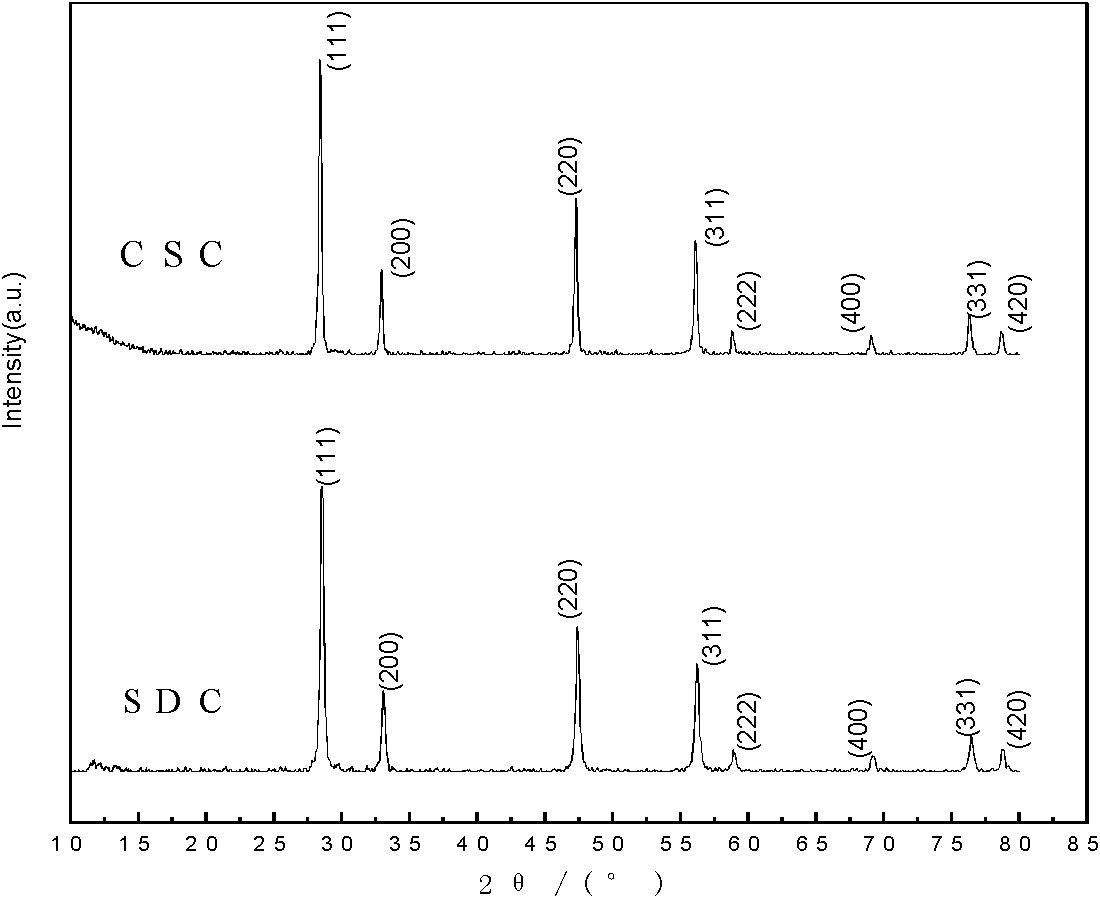

[0035] ①Electron-oxygen ion mixed conductor La 0.7 Sr 0.15 Ca 0.15 co 0.8 Fe 0.2 o 3-δ Cathode material preparation

[0036] a. La(NO 3 ) 3 ·6H 2 O(AR), Sr(NO 3 ) 2 (AR), Ca(NO 3 ) 2 4H 2 O(AR), Co(NO 3 ) 3 ·6H 2 O(AR) and Fe(NO 3 ) 3 9H 2 O(AR) by La 0.7 Sr 0.15 Ca 0.15 co 0.8 Fe 0.2 o 3-δ After weighing the stoichiometric ratio, dissolve with distilled water to form a nitrate mixed solution; be 1.5: 1 to take citric acid according to the mol ratio of citric acid (AR) and metal ion, and dissolve citric acid with distilled water;

[0037] b. Pour the citric acid solution into the nitrate mixed solution, and adjust the pH to 2 with ammonia water;

[0038] c. Stir the mixed solution magnetically at 65-75°C. With the continuous evaporation of the solvent, the solution gradually thickens and finally forms a gel; place the gel in an electric constant temperature blast drying oven at 120°C to dry the precursor ;

[0039] d. The precursor was microwave-calcin...

Embodiment 2

[0058] ①Electron-oxygen ion mixed conductor La 0.7 Sr 0.15 Ca 0.15 co 0.8 Fe 0.2 o 3-δ Cathodic material synthesis

[0059] a. La(NO 3 ) 3 ·6H 2 O, Sr(NO 3 ) 2 , Ca(NO 3 ) 2 4H 2 O, Co(NO 3 ) 3 ·6H 2 O and Fe(NO 3 ) 3 9H 2 O Press La 0.7 Sr 0.15 Ca 0.15 co 0.8 Fe 0.2 o 3-δ After the stoichiometric ratio is weighed, it is dissolved in distilled water to form a mixed solution of nitrate; the citric acid is weighed according to the molar ratio of metal ions in the mixed solution of citric acid and nitrate is 2:1, and the citric acid is dissolved in distilled water.

[0060] b. with embodiment 1.

[0061] c. With embodiment 1.

[0062] d. The precursor was microwave-calcined at 1000 °C for 1.5 h to prepare the electron-oxygen ion mixed conductor La with perovskite structure 0.7 Sr 0.15 Ca 0.15 co 0.8 Fe 0.2 o 3-δ cathode material.

[0063] Step 2. and 3. are with embodiment 1;

[0064] Wherein 4. b step is as follows, other steps are with embodime...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Power density | aaaaa | aaaaa |

| Power density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com