Titanic oxide negative electrode material used as sodium-ion battery and preparation method of thereof

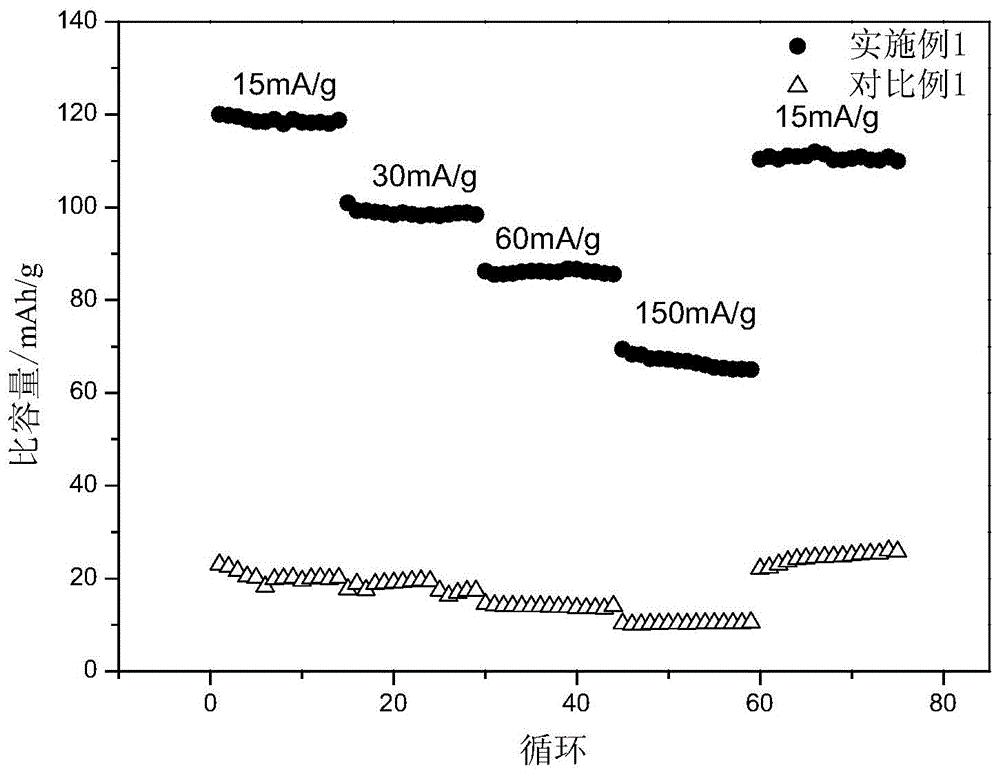

A sodium-ion battery and negative electrode material technology, which is applied in the field of energy storage materials and chemical power sources, can solve the problems of specific capacity and cycle stability to be improved, and achieve the effect of abundant raw materials, spacious ion transmission channels, and good electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

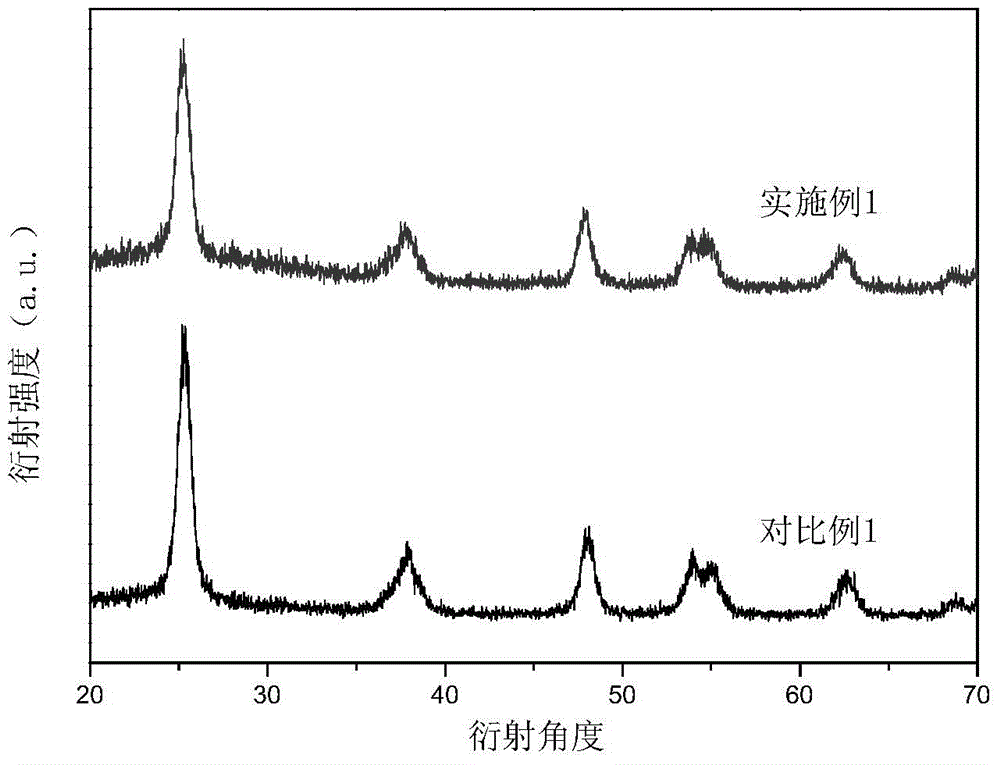

[0021] Mix 20ml of ethanol with 5ml of concentrated hydrochloric acid, and then add 0.002mol of NbCl 5 0.02 mol of tetrabutyl titanate was added under stirring, and then the solution was heated and dried under stirring. The dried product was heated up to 500° C. at a heating rate of 3° C. / min in an air atmosphere, and kept at a temperature of 5 hours to obtain the product niobium-doped titanium oxide.

Embodiment 2

[0023] Mix 30ml of ethylene glycol with 1ml of concentrated hydrochloric acid, and then add 0.004mol of NbCl 5 0.02 mol of tetrabutyl titanate was added under stirring, and then the solution was heated and dried under stirring. The dried product was heated up to 700° C. at a rate of 10° C. / min in an oxygen atmosphere, and kept at a temperature of 3 hours to obtain a product niobium-doped titanium oxide.

Embodiment 3

[0025] Mix 15ml of cyclohexane with 2ml of concentrated hydrochloric acid, and then add 0.0001mol of InCl 3 0.02 mol of tetrabutyl titanate was added under stirring, and then the solution was heated and dried under stirring. The dried product was heated to 400° C. at a heating rate of 2° C. / min under an argon atmosphere, and kept for 10 hours to obtain the product indium-doped titanium oxide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com