Preparation method of titanium dioxide negative electrode material coated with surfactant serving as carbon source

A surfactant and titanium dioxide technology, applied in the direction of active material electrodes, negative electrodes, battery electrodes, etc., can solve the problems of insufficient contact, uneven carbon layer, etc., and achieve improved electronic conductivity, wide application value, and excellent electrochemical performance. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

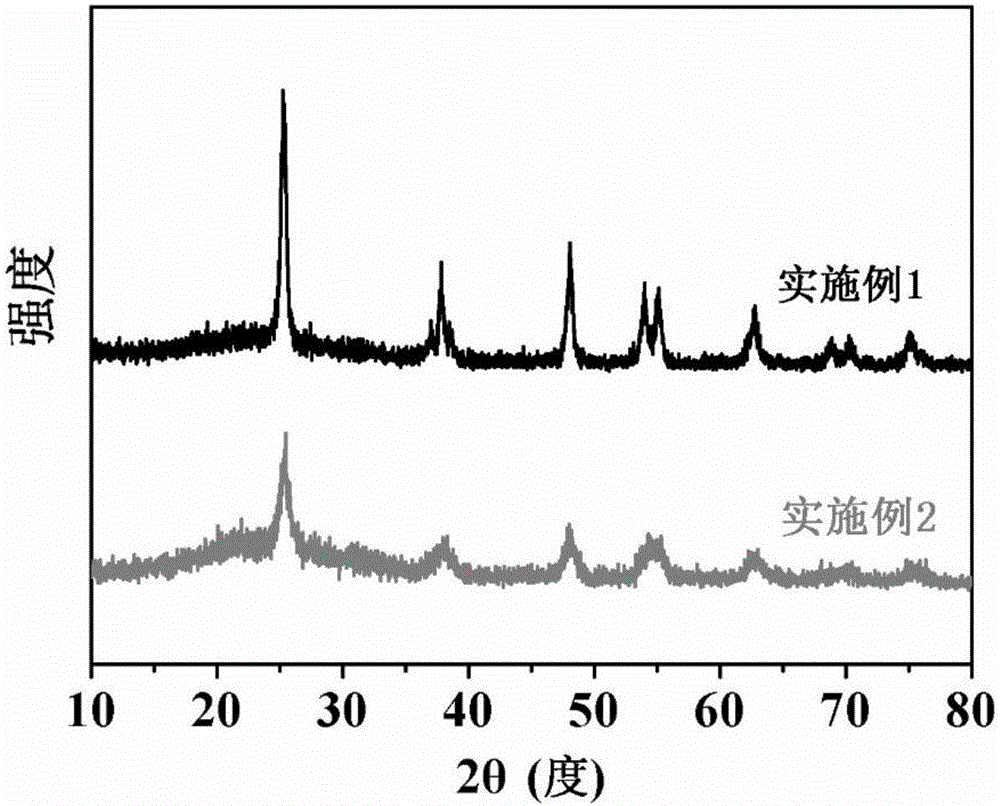

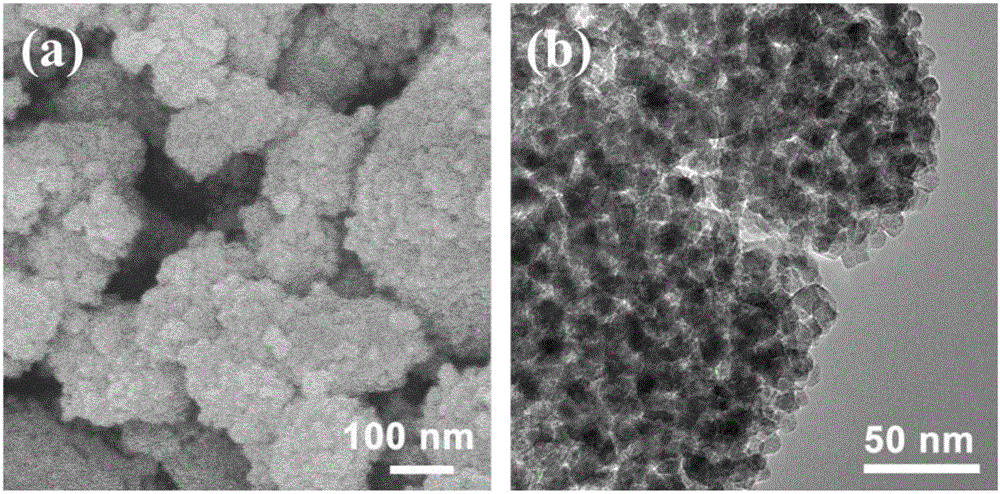

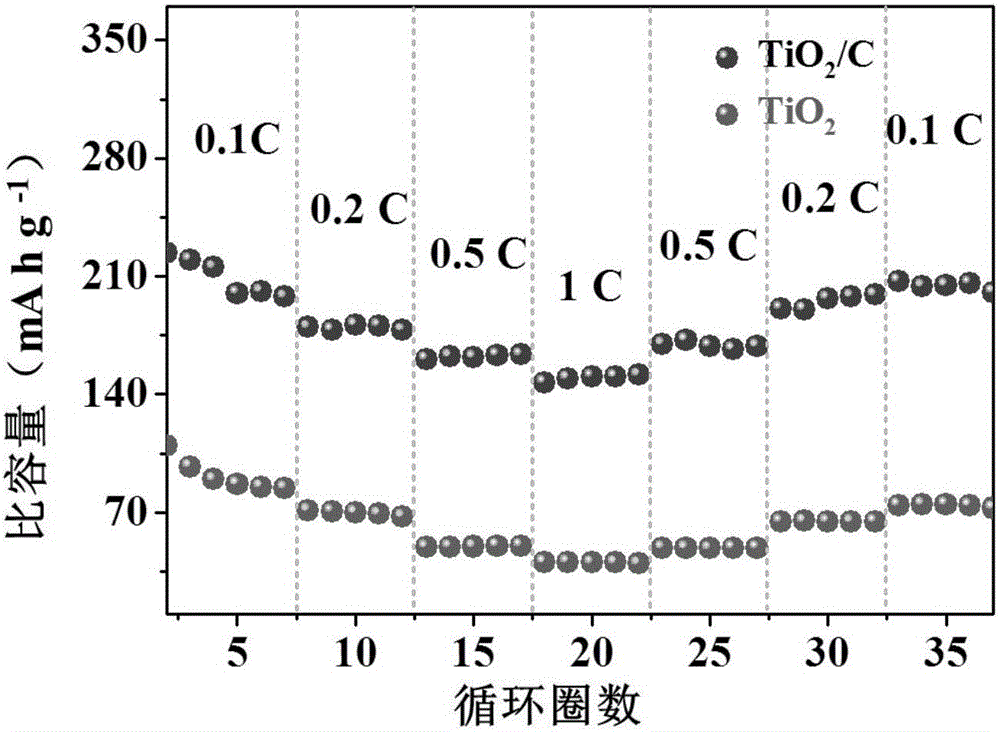

Embodiment 1

[0019] A method for preparing a titanium dioxide negative electrode material coated with a surfactant as a carbon source, using the electrostatic attraction between the cationic surfactant and the negatively charged titanium dioxide precursor titanate, and preparing it by hydrothermal method and subsequent high-temperature calcination carbon-coated titanium dioxide, the steps are as follows:

[0020] 1) Add 0.5g of cetyltrimethylammonium bromide (CTAB) into 15mL of deionized water and stir until completely dissolved; take 1.0g of tetrabutyl titanate and dissolve it in a stainless steel autoclave containing 20mL of absolute ethanol, Stir until dissolved;

[0021] 2) Slowly drop the above-prepared solution containing CTAB into the reaction kettle, mix evenly, put it in a constant temperature oven for hydrothermal reaction for 12 hours, wash the product with deionized water and absolute ethanol, centrifuge, and dry to obtain titanium dioxide powder ;

[0022] 3) Put the above t...

Embodiment 2

[0026] A method for preparing a titanium dioxide negative electrode material coated with a surfactant as a carbon source, using the electrostatic attraction between the cationic surfactant and the negatively charged titanium dioxide precursor titanate, and preparing it by hydrothermal method and subsequent high-temperature calcination carbon-coated titanium dioxide, the steps are as follows:

[0027] 1) Add 0.5g of cetyltrimethylammonium bromide (CTAB) into 15mL of deionized water and stir until completely dissolved; take 1.0g of tetrabutyl titanate and dissolve it in a stainless steel autoclave containing 20mL of absolute ethanol, Stir until dissolved;

[0028] 2) Slowly drop the above-prepared solution containing CTAB into the reaction kettle, mix evenly, put it in a constant temperature oven for hydrothermal reaction for 12 hours, wash the product with deionized water and absolute ethanol, centrifuge, and dry to obtain titanium dioxide powder ;

[0029] 3) Put the above-m...

Embodiment 3

[0034] A method for preparing a titanium dioxide negative electrode material coated with a surfactant as a carbon source, using the electrostatic attraction between the cationic surfactant and the negatively charged titanium dioxide precursor titanate, and preparing it by hydrothermal method and subsequent high-temperature calcination carbon-coated titanium dioxide, the steps are as follows:

[0035] 1) Add 0.5g of cetyltrimethylammonium chloride (CTAC) into 15mL of deionized water and stir until completely dissolved; take 1.0g of tetrabutyl titanate and dissolve it in a stainless steel autoclave containing 20mL of absolute ethanol, Stir until dissolved;

[0036] 2) Slowly drop the above-prepared solution containing CTAB into the reaction kettle, mix evenly, put it in a constant temperature oven for hydrothermal reaction for 12 hours, wash the product with deionized water and absolute ethanol, centrifuge, and dry to obtain titanium dioxide powder ;

[0037] 3) Put the above-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com