Method for preparing bamboo shoot shell-based activated carbon for super capacitor

A technology of supercapacitor and bamboo shoot shell, which is applied to the preparation of bamboo shoot shell-based activated carbon for supercapacitors and the field of activated carbon preparation, can solve the problems of no activated carbon performance parameters and application, performance needs to be improved, and application performance is limited, and achieves good commercial application. Prospects, easy to large-scale industrial production, the effect of abundant resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

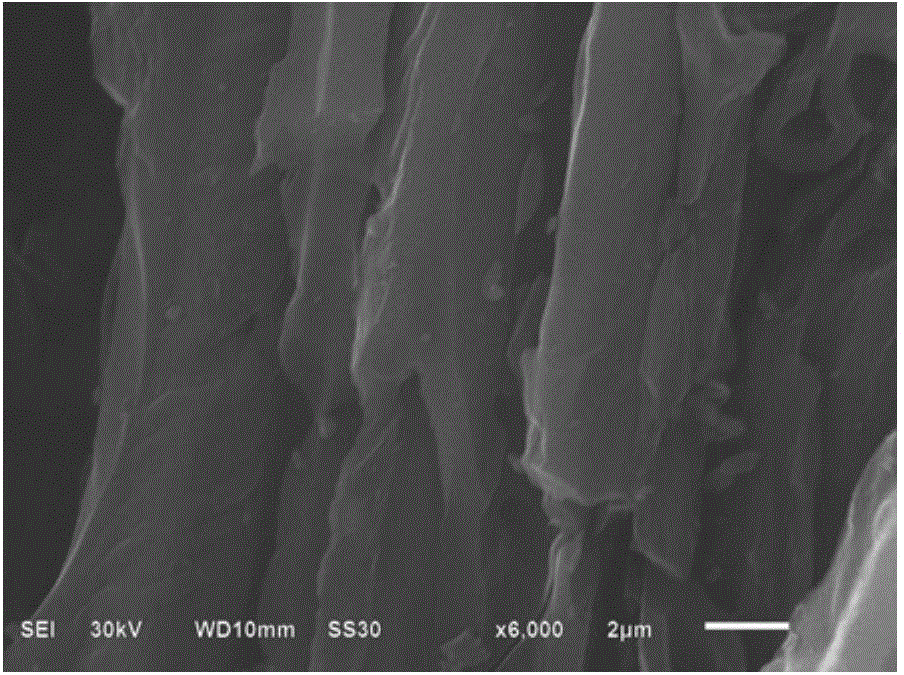

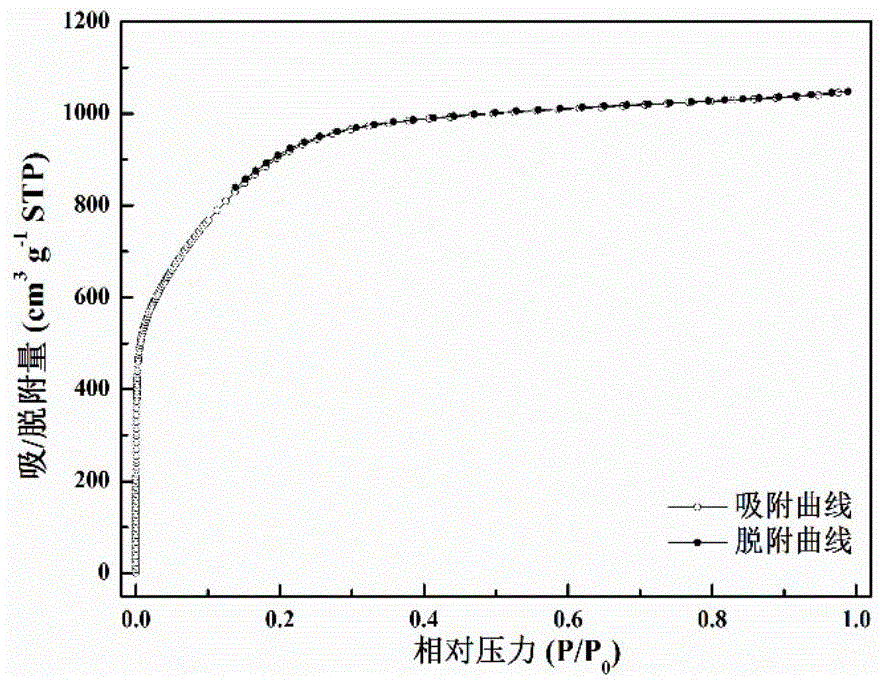

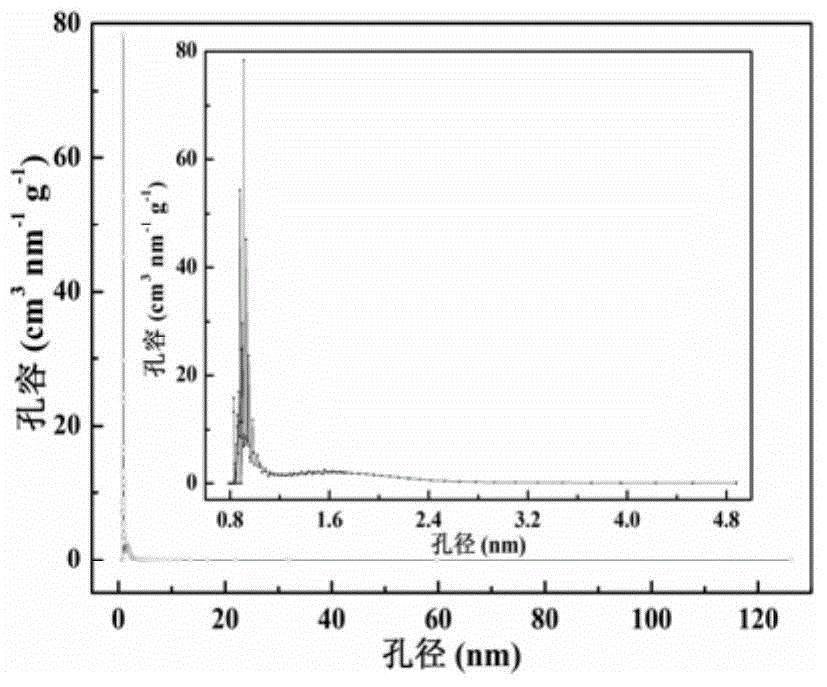

Embodiment 1

[0031] Soak the bamboo shoot shells in water, scrub them clean, put them into an oven, and dry them at a constant temperature at 100°C for 12 hours. Cut the dried bamboo shoot shells to about 0.5cm 2sized pieces. Then weigh 1 kg of bamboo shoot shell fragments, put them into a vacuum furnace, pass through argon protection, set the heating rate to 5°C / min, heat up to 350°C, keep the temperature constant for 1h, and then rise to 600°C at a heating rate of 10°C / min. Constant temperature 2h. Grind the obtained bamboo shoot shell carbonization product into a fine powder, pass through a 200 mesh sieve, then soak the powder with nitric acid with a mass fraction of 5%, heat to boiling, reflux for 1 hour, cool to room temperature, filter, wash the bamboo shoot shell carbonization product to the filtrate Neutral. The filter cake was put into a blast drying oven, and dried at a constant temperature of 80° C. for 12 hours to obtain bamboo shoot charcoal. Weigh 100g dried bamboo shoot ...

Embodiment 2

[0033] Soak the bamboo shoot shells in water, scrub them clean, put them into an oven, and dry them at a constant temperature at 100°C for 12 hours. Grind the dried bamboo shoot shells into powder. Then weigh 1 kg of bamboo shoot shell powder, put it into a vacuum furnace, pass through nitrogen protection, set the heating rate to 5°C / min, raise the temperature to 350°C, keep the temperature constant for 1h, then rise to 500°C at a heating rate of 10°C / min, and keep the temperature constant 2h. Grind the obtained bamboo shoot shell carbonization product into fine powder, pass through a 200 mesh sieve, then soak the powder with hydrochloric acid with a mass fraction of 10%, heat to boiling, reflux for 1 hour, cool to room temperature, filter, wash the bamboo shoot shell carbonization product to the filtrate Neutral. The filter cake was put into a blast drying oven, and dried at a constant temperature of 80° C. for 12 hours to obtain bamboo shoot charcoal. Weigh 100g dried bam...

Embodiment 3

[0035] Soak the bamboo shoot shells in water, scrub them clean, put them into an oven, and dry them at a constant temperature at 100°C for 12 hours. Cut the dried bamboo shoot shells to about 1cm 2 sized pieces. Then weigh 1 kg of bamboo shoot shell fragments, put them into a vacuum furnace, pass in nitrogen protection, set the heating rate to 5°C / min, raise the temperature to 350°C, keep the temperature constant for 1h, then rise to 500°C at a heating rate of 10°C / min, and keep the temperature constant 2h. Grind the obtained bamboo shoot shell carbonization product into fine powder, pass through a 200 mesh sieve, then soak the powder with hydrochloric acid with a mass fraction of 10%, heat to boiling, reflux for 1 hour, cool to room temperature, filter, wash the bamboo shoot shell carbonization product to the filtrate Neutral. The filter cake was put into a blast drying oven, and dried at a constant temperature of 80° C. for 12 hours to obtain bamboo shoot charcoal. Weigh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific capacitance | aaaaa | aaaaa |

| Specific capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com