Preparation method of nitrogen-doped graphene

A nitrogen-doped graphene and precursor technology, applied in the field of nitrogen-doped graphene preparation, can solve problems such as environmental pollution, polluting products, and difficulty in mass production of nitrogen-doped graphene, and achieve excellent performance and appearance. uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

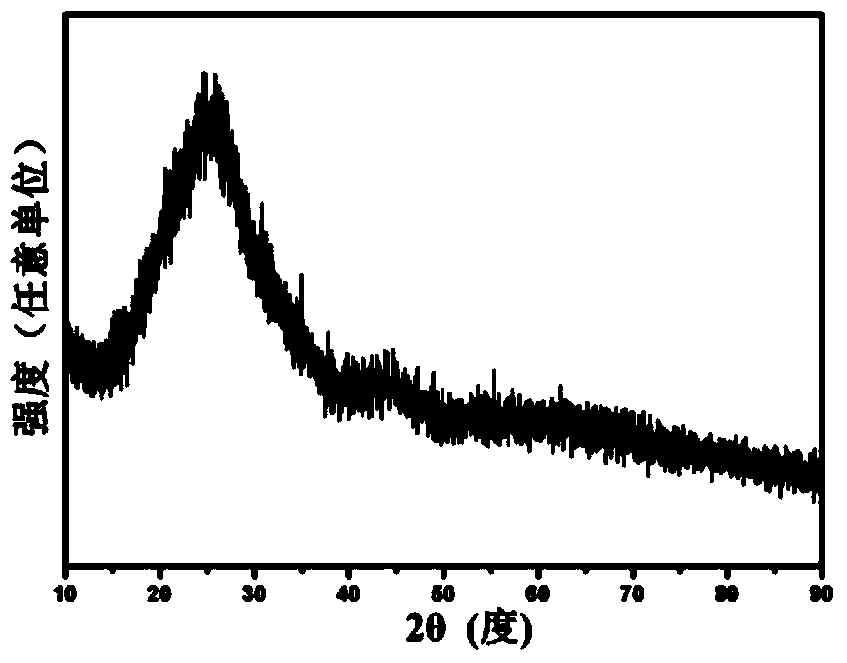

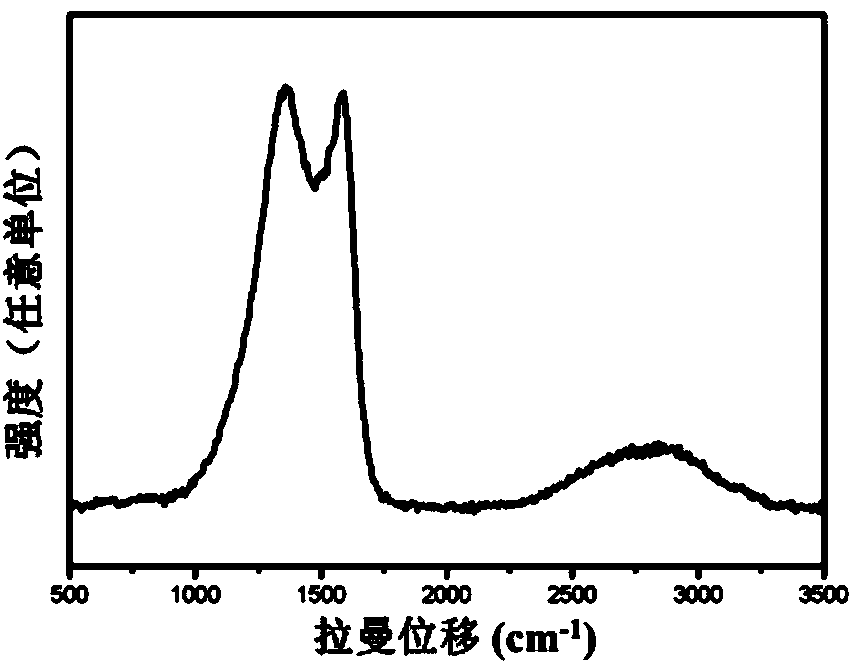

Image

Examples

Embodiment 1

[0019] The first step, the specific steps of preparing the precursor are as follows: the precursor is prepared in the following way: get 1.1g citric acid and 28.9g melamine (molar ratio is 1: 40), add in 150ml of anhydrous methanol, at room temperature Stir at a rate of 1000r / min for 10min, put the sample into a probe-type ultrasonic processor, and ultrasonicate for 10min in an ice-water bath at a power of 20kHz and 400W. Take out the sample after ultrasonication, heat it in a water bath at 80°C and stir it at a rate of 1000r / min until the sample has no obvious liquid water, move it into a blast drying oven, and dry it at 80°C for 24h to obtain the desired precursor.

[0020] In the second step, the precursor calcination process is as follows: put the precursor sample obtained above into a 100×50×50 cm boat-shaped crucible, cover it, place it in a tube furnace, and heat it at 6°C / min under an inert gas atmosphere Calcined at 600°C for 2h at a heating rate of 7°C / min, then calc...

Embodiment 2

[0024] The first step, the specific steps of preparing the precursor are as follows: the precursor is prepared in the following way: get 1.2g citric acid and 23.8g melamine (molar ratio is 1:30), add in 130ml of anhydrous methanol, at room temperature Stir at a rate of 800r / min for 20min, put the sample into a probe-type ultrasonic processor, and ultrasonicate for 15min in an ice-water bath at a power of 20kHz and 300W. The sample after ultrasonication was taken out, heated in a water bath at 70°C and stirred at a rate of 800r / min until the sample had no obvious liquid water, then moved into a blast drying oven, and dried at 70°C for 36h to obtain the desired precursor.

[0025] In the second step, the precursor calcination process is as follows: put the precursor sample obtained above into a 100×50×50 cm boat-shaped crucible, cover it, place it in a tube furnace, and heat it at 4°C / min under an inert gas atmosphere Calcined at 550°C for 2.5h at a heating rate of 5°C / min, then...

Embodiment 3

[0029] The first step, the specific steps of preparing the precursor are as follows: the precursor is prepared in the following way: get 1.4g citric acid and 18.6g melamine (molar ratio is 1:20), add in 100ml of anhydrous methanol, at room temperature Stir at a rate of 600r / min for 30min, put the sample into a probe-type ultrasonic processor, and ultrasonicate for 20min in an ice-water bath at a power of 20kHz and 200W. Take out the sample after ultrasonication, heat it in a water bath at 60°C and stir it at a speed of 600r / min until the sample has no obvious liquid water, move it into a blast drying oven, and dry it at 60°C for 48h to obtain the desired precursor.

[0030] In the second step, the precursor calcination process is as follows: put the precursor sample obtained above into a 100×50×50 cm boat-shaped crucible, cover it, place it in a tube furnace, and heat it at 2°C / min under an inert gas atmosphere Calcined at 500°C for 3h at a heating rate of 3°C / min, then calcin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore volume | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Average pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com