Castable magnesium alloys

A technology for casting alloys and magnesium-based alloys, applied in the field of magnesium-based alloys, can solve problems such as poor casting performance and achieve good performance

Active Publication Date: 2006-01-04

MAGNESIUM ELETRON LTD

View PDF4 Cites 36 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0071] 1. Example - Corrosion Test 1

[0072] An initial set of experiments was performed to determine the general influence of the following factors on the corrosion performance of the alloys of the invention:

[0073] ●alloy chemical properties

[0074] ● Melting variable

[0075] ●Surface preparation

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

Login to View More

Abstract

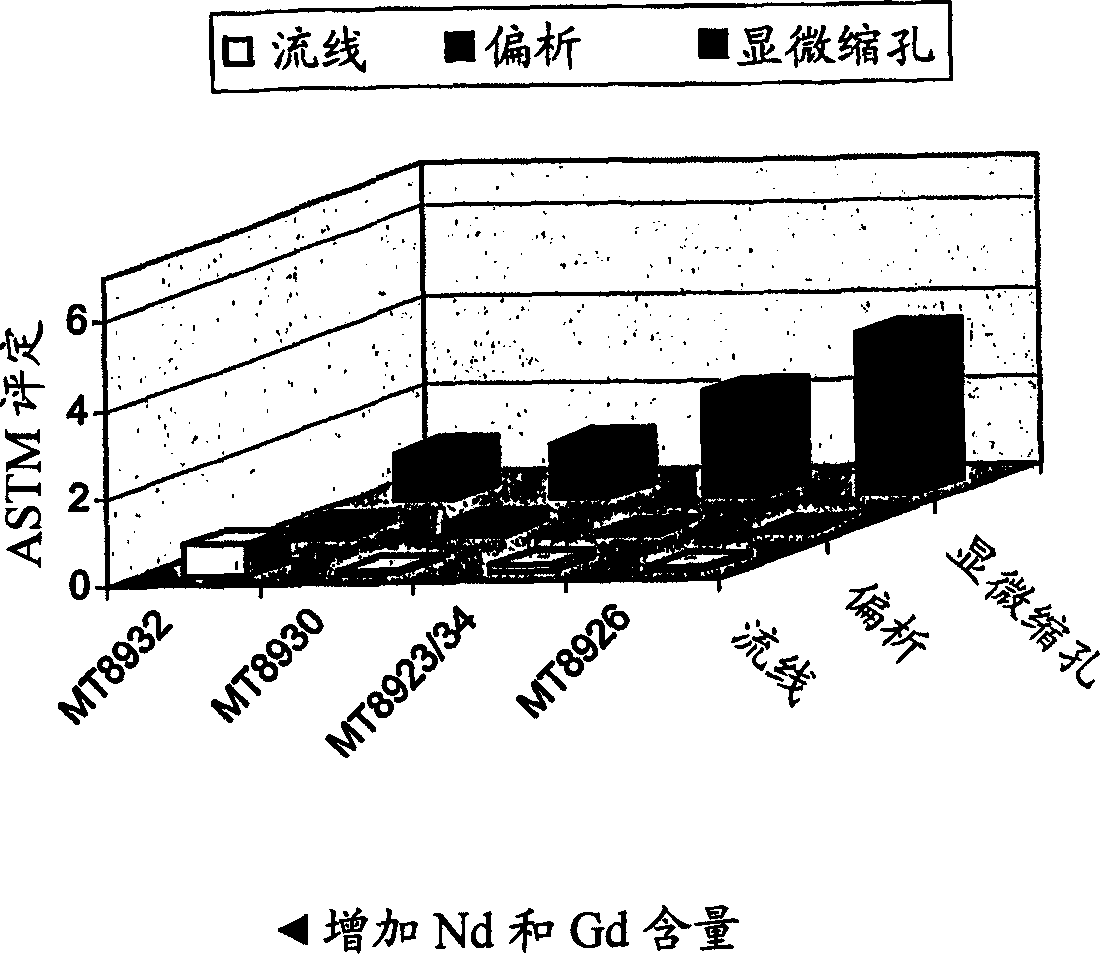

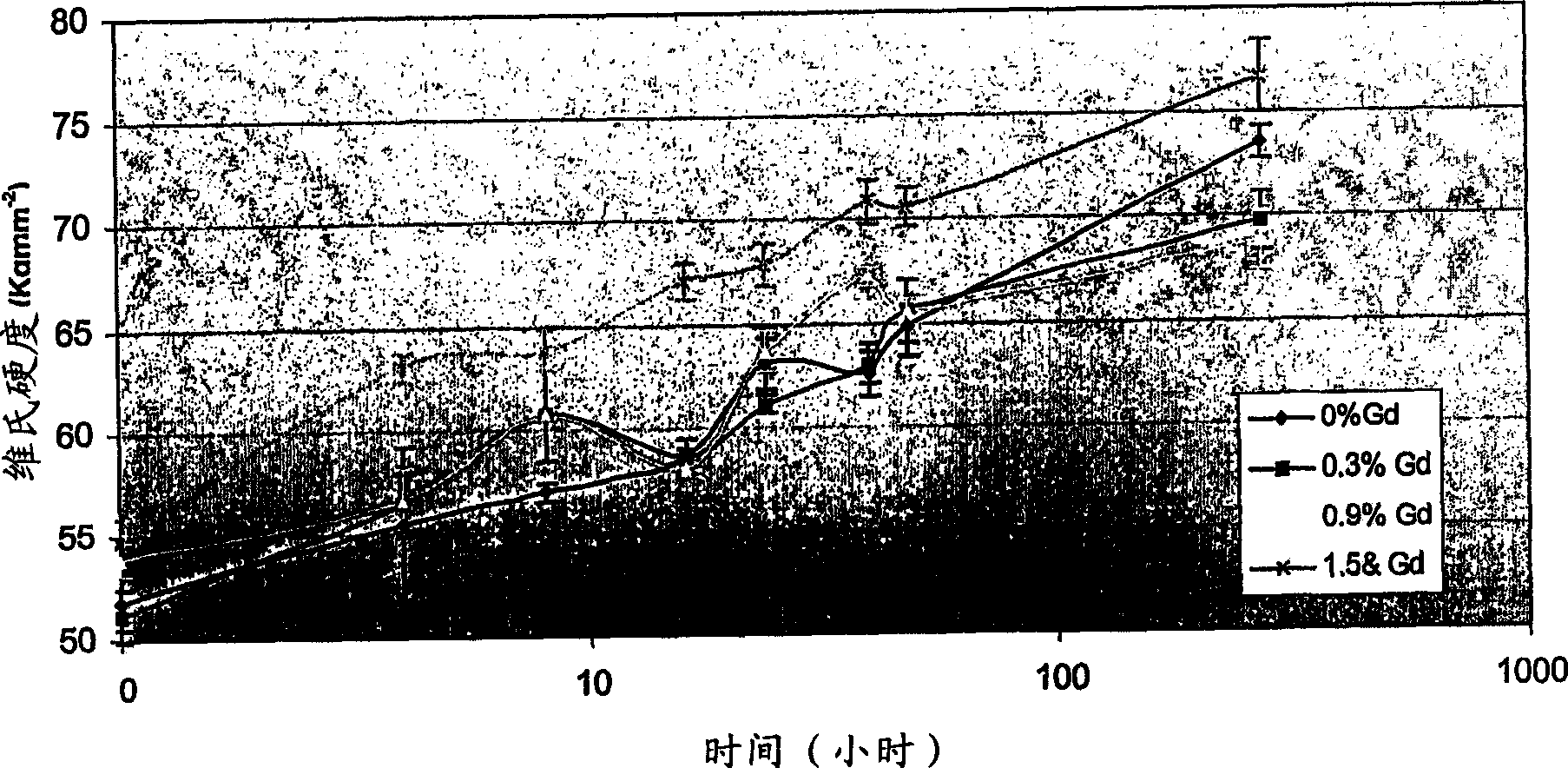

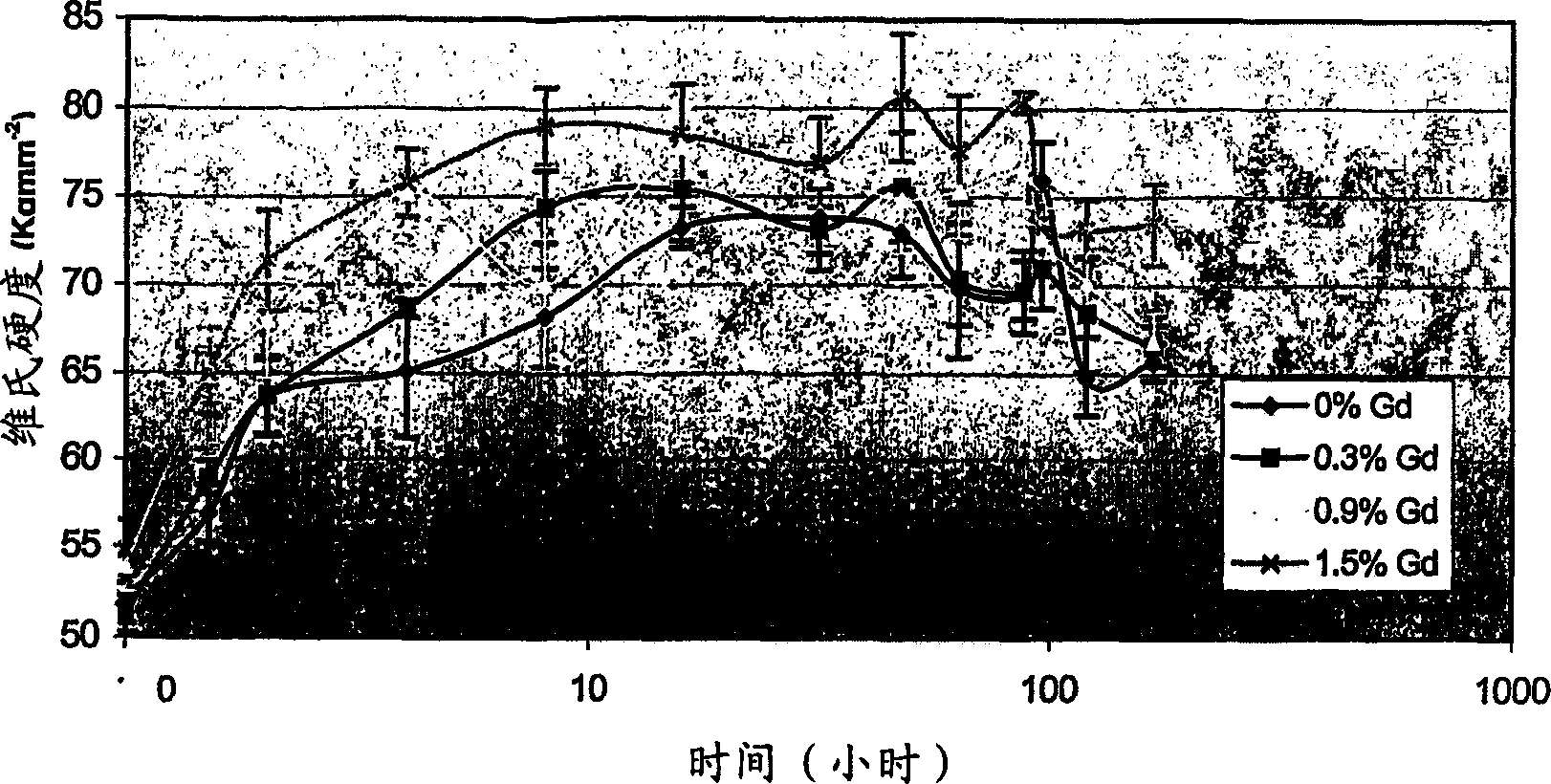

This invention relates to magnesium-based alloys particularly suitable for casting applications where good mechanical properties at room and at elevated temperatures are required. The alloys contain: 2 to 4.5% by weight of neodymium; 0.2 to 7.0 of at least one rare earth metal of atomic No. 62 to 71; up to 1.3% by weight of zinc; and 0.2 to 0.7% by weight of zirconium; optionally with one or more other minor component They are resistant to corrosion, show good age-hardening behaviour, and are also suitable for extrusion and wrought alloy applications.

Description

technical field [0001] The present invention relates to magnesium-based alloys particularly suitable for casting applications, which have good mechanical properties at room and elevated temperatures. Background technique [0002] Magnesium-based alloys are often used in aerospace applications due to their high strength and light weight, where components such as helicopter gearboxes and jet engine components are suitable for sand casting. Such aerospace alloys have been developed during the last 20 years in an attempt to obtain good corrosion resistance in such alloys without loss of strength at high temperatures such as up to 200°C. [0003] A particular area of research is magnesium-based alloys, which contain one or more rare earth (RE) elements. For example, WO 96 / 24701 describes a magnesium alloy particularly suitable for high pressure die casting which contains 2% to 5% by weight of rare earth metals in combination with 0.1% to 2% of zinc. In this specification, "ra...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C22C23/06

CPCC22C23/06C22F1/06C22C23/00

Inventor 保罗·莱昂约翰·金侯赛因·卡里姆扎德伊斯梅特·赛义德

Owner MAGNESIUM ELETRON LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com