Preparation method of immobilized beta-glucosidase

A technology of glucosidase and fructose, which is applied in directions such as being fixed on/in an organic carrier, can solve the problems of high production and use costs, inactivation of β-glucosidase, etc., and achieves a simple removal method without pollution, load The effect of high amount and reducing the cost of enzymatic hydrolysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

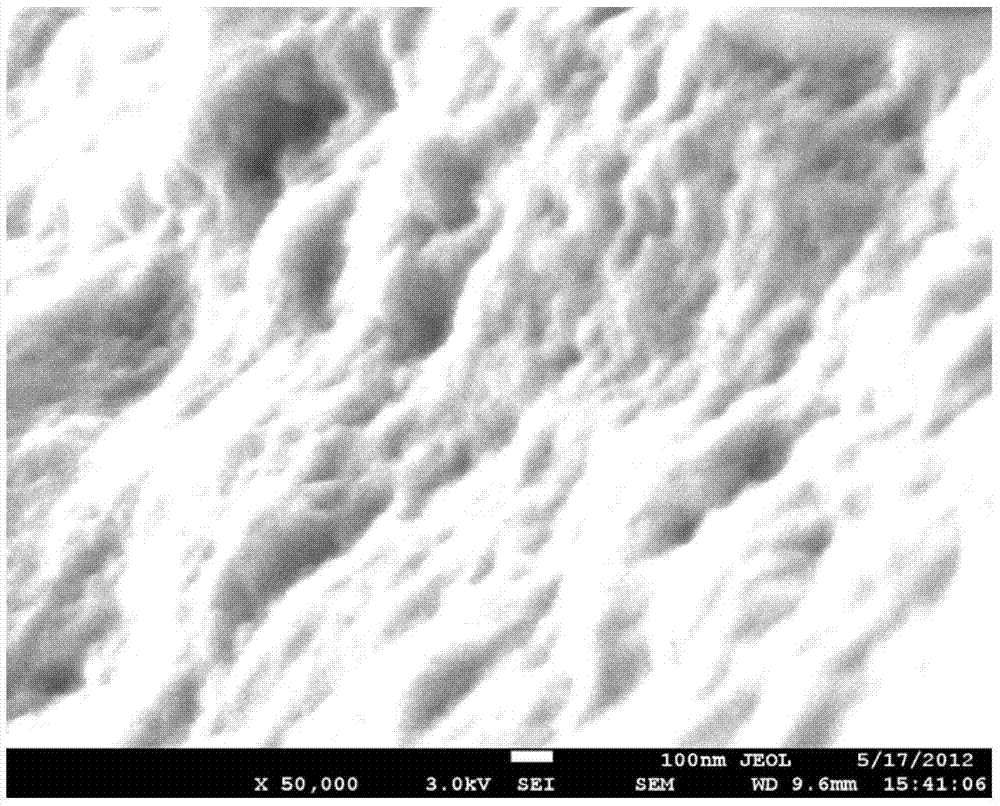

[0047] Add 32g of tetraethyl orthosilicate and 7.5mL of 0.034mol hydrochloric acid into a 500mL three-neck round bottom flask, under nitrogen atmosphere, magnetically stir (1500rpm) for 15min, then raise the temperature of the water bath, and reflux for 1h when it rises to 60°C , then cooled to room temperature and degassed with nitrogen.

[0048] Vacuum was applied under magnetic stirring until the weight loss was about 50%. Add 50% fructose aqueous solution, stir evenly, and then sonicate for 5 minutes to remove air bubbles. The obtained liquid was evenly divided into three 100mL small beakers, and 1.155mL of enzyme solution (a mixture of β-glucosidase and 50mM, pH5.0 acetate buffer solution) was added, stirred for 2min, sealed with plastic wrap, and Prick 30-40 holes on the membrane and put it in a refrigerator at 4°C for 48 hours to make it gel.

[0049] After 48 hours, put the gelled immobilized β-glucosidase sample into a vacuum drying oven to dry in vacuum until the wei...

Embodiment 2

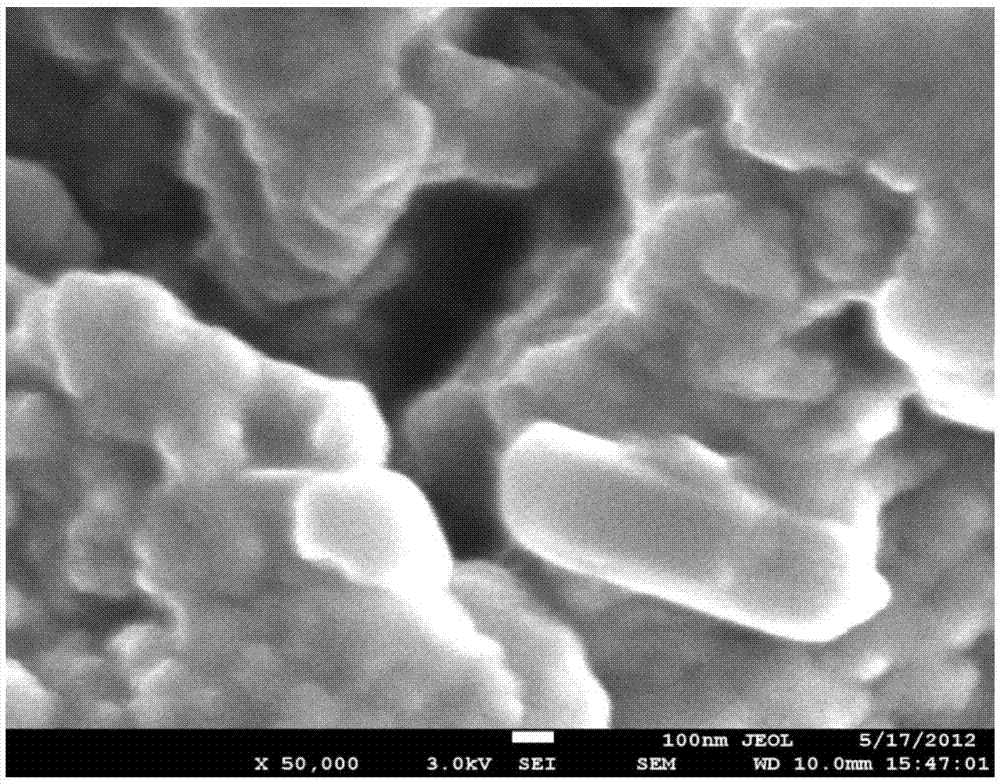

[0052] Add 32g of tetraethyl orthosilicate and 7.5mL of 0.034mol hydrochloric acid into a 500mL three-neck round bottom flask, under nitrogen atmosphere, magnetically stir (1500rpm) for 15min, then raise the temperature of the water bath, and reflux for 2h when it rises to 55°C , then cooled to room temperature and degassed with nitrogen.

[0053] Vacuum was applied under magnetic stirring until the weight loss was about 50%. Add 50% fructose aqueous solution, stir evenly, and then sonicate for 5 minutes to remove air bubbles. The obtained liquid was evenly divided into three 100mL small beakers, and 2.31mL of enzyme solution (a mixture of β-glucosidase and 50mM, pH5.0 acetate buffer solution) was added, stirred for 2min, sealed with plastic wrap, and Prick 30-40 holes on the membrane and put it in a refrigerator at 4°C for 96 hours to make it gel.

[0054] After 96 hours, put the gelatinized immobilized β-glucosidase sample into a vacuum drying oven for vacuum drying until ...

Embodiment 3

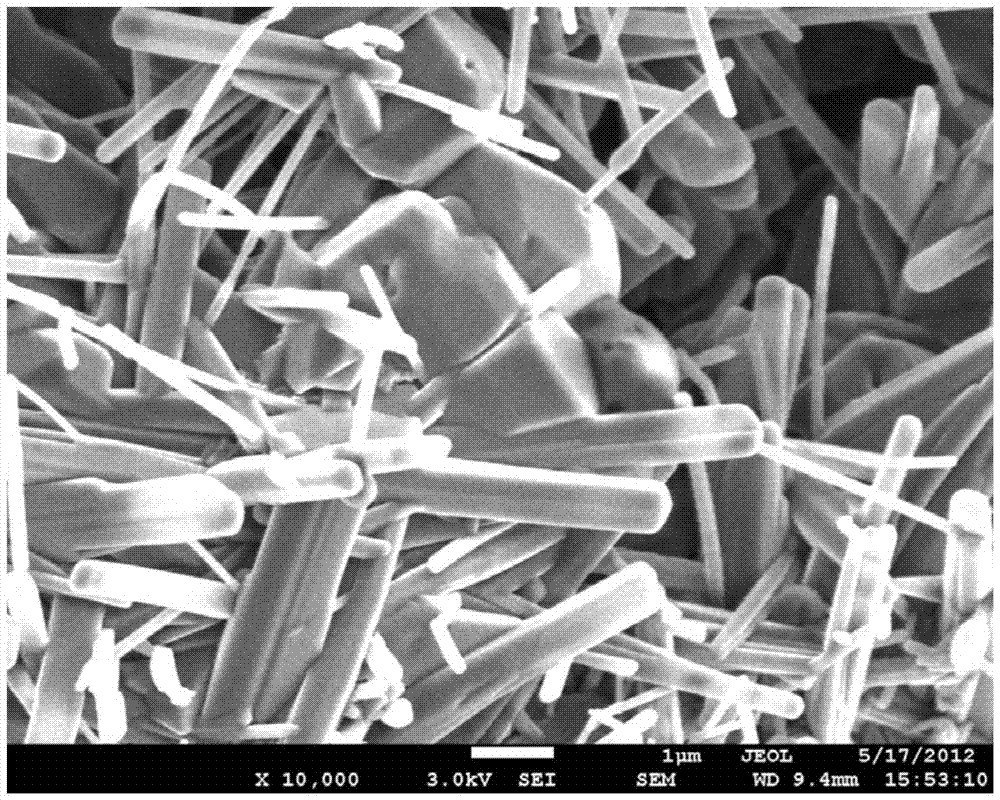

[0056] Add 32g of tetraethyl orthosilicate and 7.5mL of 0.034mol hydrochloric acid into a 500mL three-neck round bottom flask, under nitrogen atmosphere, magnetically stir (1500rpm) for 15min, then increase the temperature of the water bath, and reflux for 1h when it rises to 65°C , then cooled to room temperature and degassed with nitrogen.

[0057] Vacuum was applied under magnetic stirring until the weight loss was about 50%. Add 60% fructose aqueous solution, stir evenly, and then sonicate for 5 minutes to remove air bubbles. The obtained liquid was evenly divided into three 100mL small beakers, and 1.155mL of enzyme solution (a mixture of β-glucosidase and 50mM, pH5.0 acetate buffer solution) was added, stirred for 2min, sealed with plastic wrap, and Prick 30-40 holes on the membrane and put it in a refrigerator at 4°C for 48 hours to make it gel.

[0058] After 48 hours, put the gelled immobilized β-glucosidase sample into a vacuum drying oven to dry in vacuum until th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com