Novel technique for purifying high-quality propylene glycol in production process of dimethyl carbonate

A kind of technology of dimethyl carbonate, production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

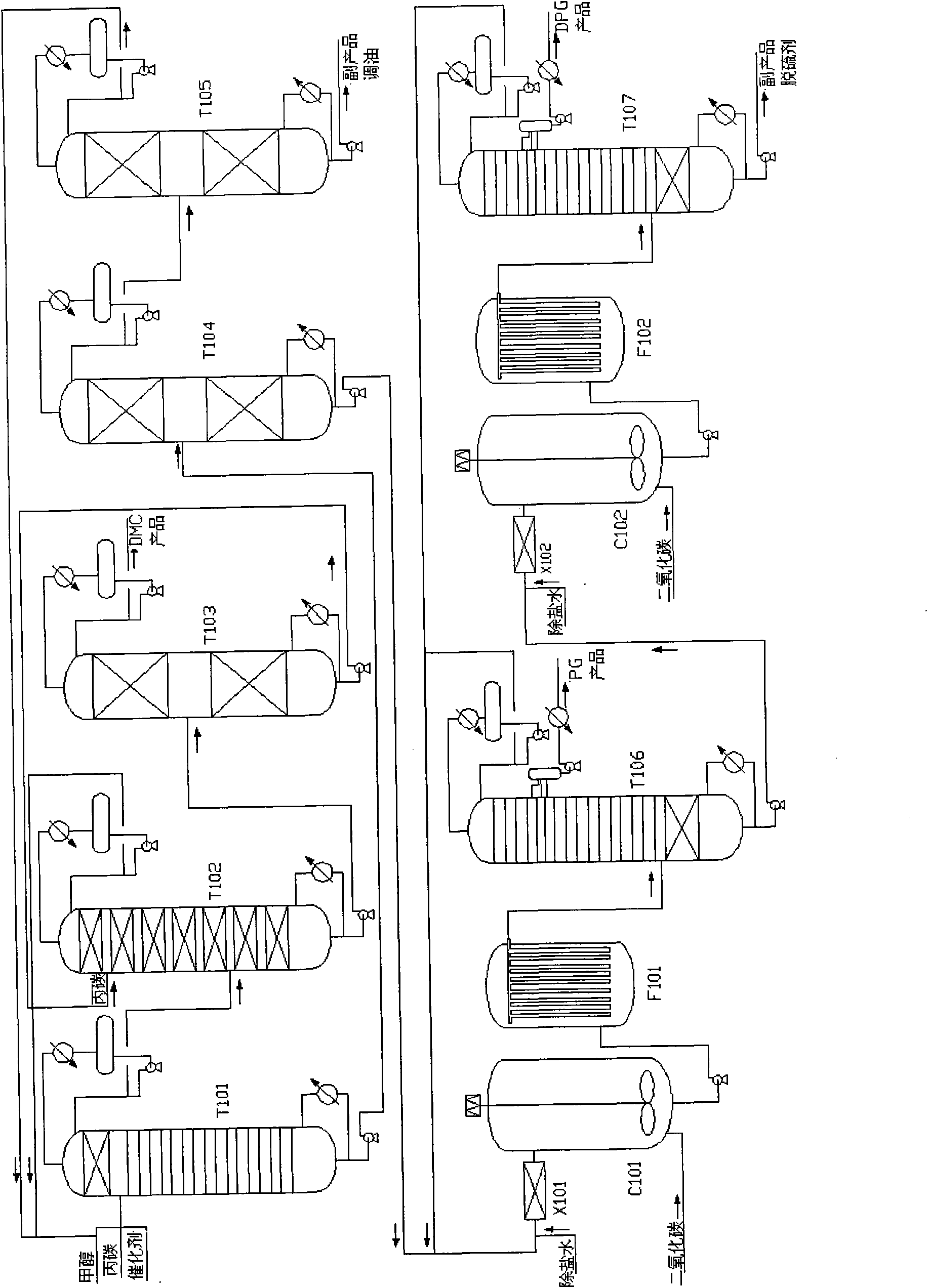

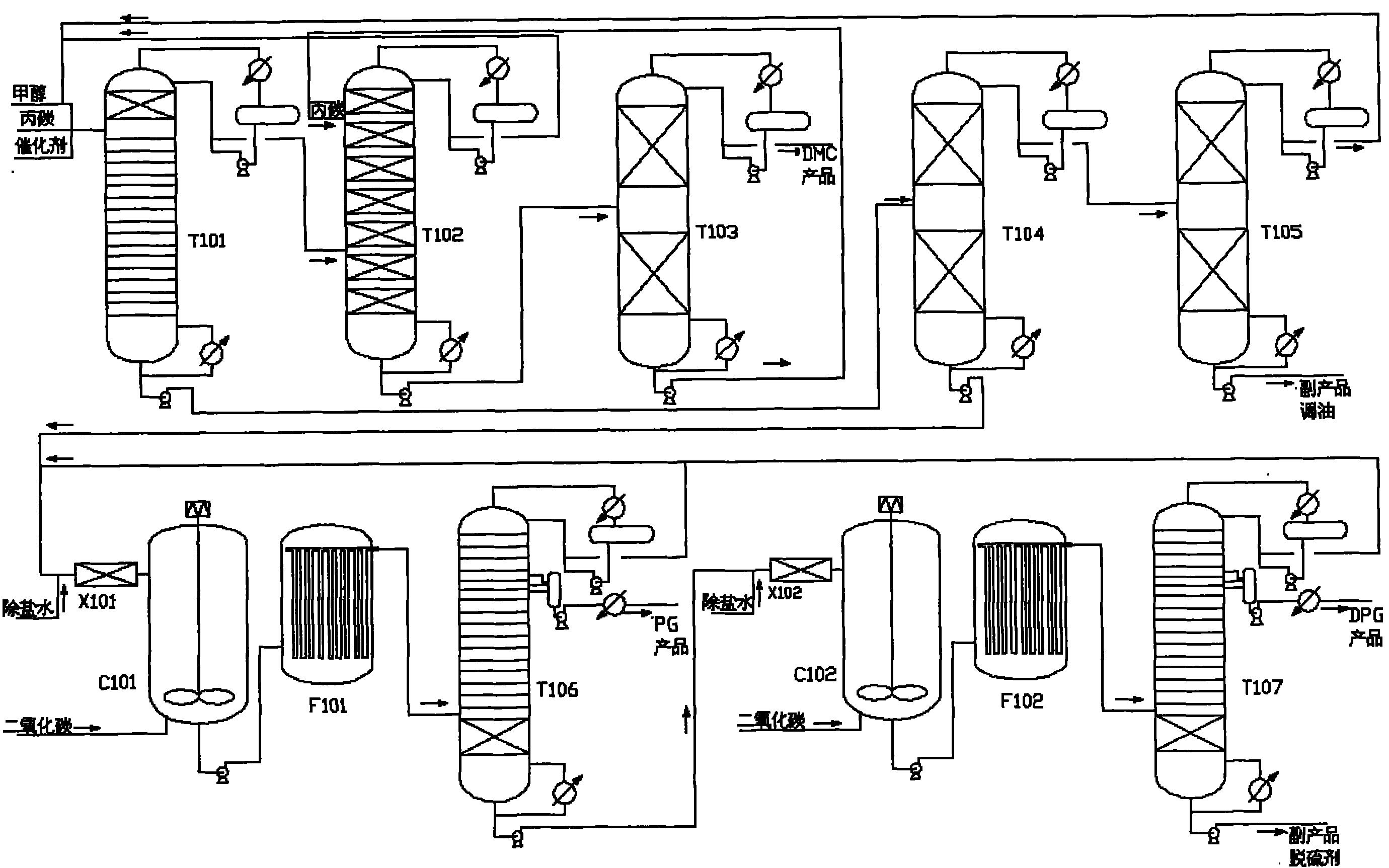

[0042] combined with figure 1 , the present invention comprises the following steps:

[0043] 1. Reactive distillation: Reactive distillation of methanol and propylene carbonate: propylene carbonate, methanol and catalyst sodium methoxide are mixed into the static mixer through the feed pump, and the mixed materials enter the reactive distillation tower T101 . Control the mol ratio of methyl alcohol and propylene carbonate in the reactive rectification tower to be: 8~15: 1, control the content of catalyst sodium methylate on each layer tray in the reactive rectification tower at 0.20%~0.80% (mass percentage). Control the reaction temperature of the reactive distillation tower at 50°C to 100°C, the pressure at 0.060MPa to 0.20MPa, the reflux ratio at 0.30 to 2.0, and the reaction residence time at 0.35 to 1.5 hours. The azeotrope of methanol and dimethyl carbonate obtained at the top of the tower enters the extractive distillation column T102 for separation. And the still li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com