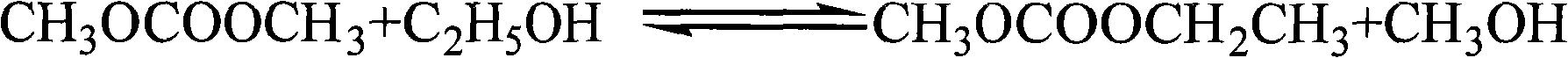

Method for preparing methyl ethyl carbonate

A technology of ethyl methyl carbonate and dimethyl carbonate, applied in the field of preparation of ethyl methyl carbonate, can solve problems such as many side reactions and low yields

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] Preparation of absolute ethanol

[0022] Add 200 grams of 5A molecular sieves to 1000 ml of commercially available ethanol (Guangzhou Chemical Reagent Factory, analytically pure); after sealing and standing for 24 hours, take the supernatant to obtain absolute ethanol. Tested by Swiss Metrohm KF831 moisture tester, the moisture content of the absolute ethanol is 0.02%.

Embodiment 1

[0024] In a 500ml round-bottomed three-necked bottle, add 270 grams (3.0 moles) of dimethyl carbonate, 69 grams (1.5 moles) of absolute ethanol after dehydration treatment, 10 grams (0.25 moles) of catalyst sodium hydroxide, and put In the water bath, heat while stirring, control the temperature rise rate to 5°C / hour, when the reaction temperature rises to 50°C, stop the temperature rise, maintain this temperature, and react for about 2 hours. After the reaction, stop stirring, and cool the reaction solution to 25°C, release the product in the kettle, filter, take the filtrate for atmospheric distillation, collect and separate the solvent dimethyl carbonate in sections, collect 108-110°C fractions, and obtain 122.0g Colorless liquid, product yield 78.2%, carry out gas chromatography-mass spectrometry (GC-MS) to product and carry out qualitative analysis, then carry out quantitative analysis with gas chromatography (GC), record product purity and be 99.9% methyl carbonate Ethyl...

Embodiment 2

[0026] In a 500ml round-bottomed three-necked bottle, add 360 grams (4.0 moles) of dimethyl carbonate, 46 grams (1.0 moles) of dehydrated ethanol after dehydration treatment, and 8 grams (0.2 moles) of catalyst sodium hydroxide, and put into a constant temperature In the water bath, start stirring. Then heat, the temperature of the reaction mixture is raised, and the temperature rise rate is controlled at 7°C / hour. When the reaction temperature rises to 55°C, the temperature rise is stopped and the temperature is maintained for about 3 hours. After the reaction is over, stop stirring and cool to 25°C, release the product in the kettle, filter, take the filtrate and carry out atmospheric distillation, collect and separate the solvent dimethyl carbonate in sections, and then collect 108~110°C fractions to obtain 83.5g colorless liquid Product yield 80.3%, ethyl methyl carbonate purity testing method is the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com