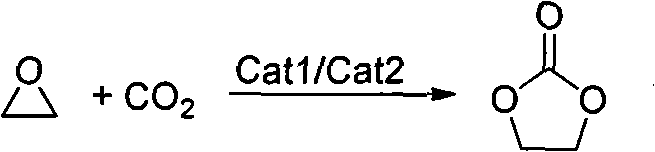

Catalytic method for preparing dimethyl cabonate along with ethylene glycol

A technology of dimethyl carbonate and ethylene glycol, which is applied in clean catalysis and green fields, and can solve problems such as incompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

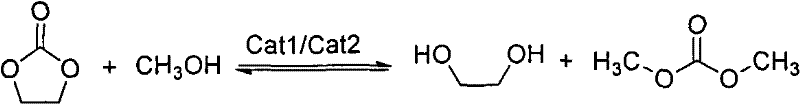

Method used

Image

Examples

Embodiment 1

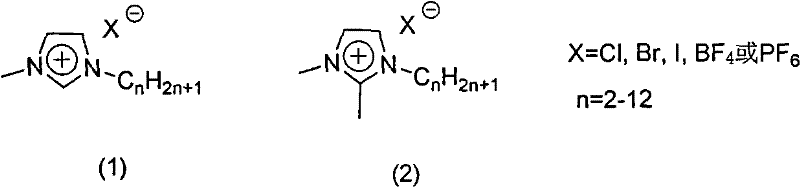

[0013] (a) Implementation method: In a 100mL stainless steel autoclave, add 0.2mol of ethylene oxide, 4mmol of 1-butyl-3-methylimidazole brominated by composite catalyst, K 2 CO 3 1mmol, airtight reaction kettle, filled with carbon dioxide of appropriate pressure, controlled temperature by temperature controller to slowly rise to 393K, then control carbon dioxide pressure to 2.0MPa, react for 1 hour, cool to room temperature, unload the kettle, excess carbon dioxide with saturated sodium carbonate solution absorption, and the resulting mixed solution was analyzed by gas chromatography, the product selectivity was 99%, and the yield was 98%.

[0014] (b) Implementation method: add methanol 1.6mol in the original reactor and the ethylene carbonate and composite catalyst mixed solution generated in (a), seal the reactor, and slowly rise to 383K by the temperature controller, and react 1

[0015] h, cooled to room temperature, and the resulting mixed solution was analyzed by gas ...

Embodiment 2

[0017] (a) implementation method: with embodiment 1, add composite catalyst chloride 1-ethyl-3-methylimidazole 2mmol, Na 2 CO 3 1 mmol, the time is 6 hours, and other things are unchanged, the selectivity of ethylene carbonate is 99%, and the yield is 98%.

[0018] (b) Implementation method: with embodiment 1, add methyl alcohol 0.8mol, other is constant, obtains ethylene carbonate conversion rate 62%, the selectivity of ethylene glycol 99%, the selectivity of dimethyl carbonate is 99%.

Embodiment 3

[0020] (a) implementation method: with embodiment 1, add composite catalyst iodide 1-dodecyl-3-methylimidazole 2mmol, K 2 CO 3 2mmol, the reaction pressure is 10MPa, and other things remain unchanged, the selectivity of ethylene carbonate is 99%, and the yield is 97%.

[0021] (b) Implementation method: with embodiment 1, the time is 0.5 hour, other is constant, obtains ethylene carbonate transformation rate 68%, the selectivity 99% of ethylene glycol, the selectivity of dimethyl carbonate is 99%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com