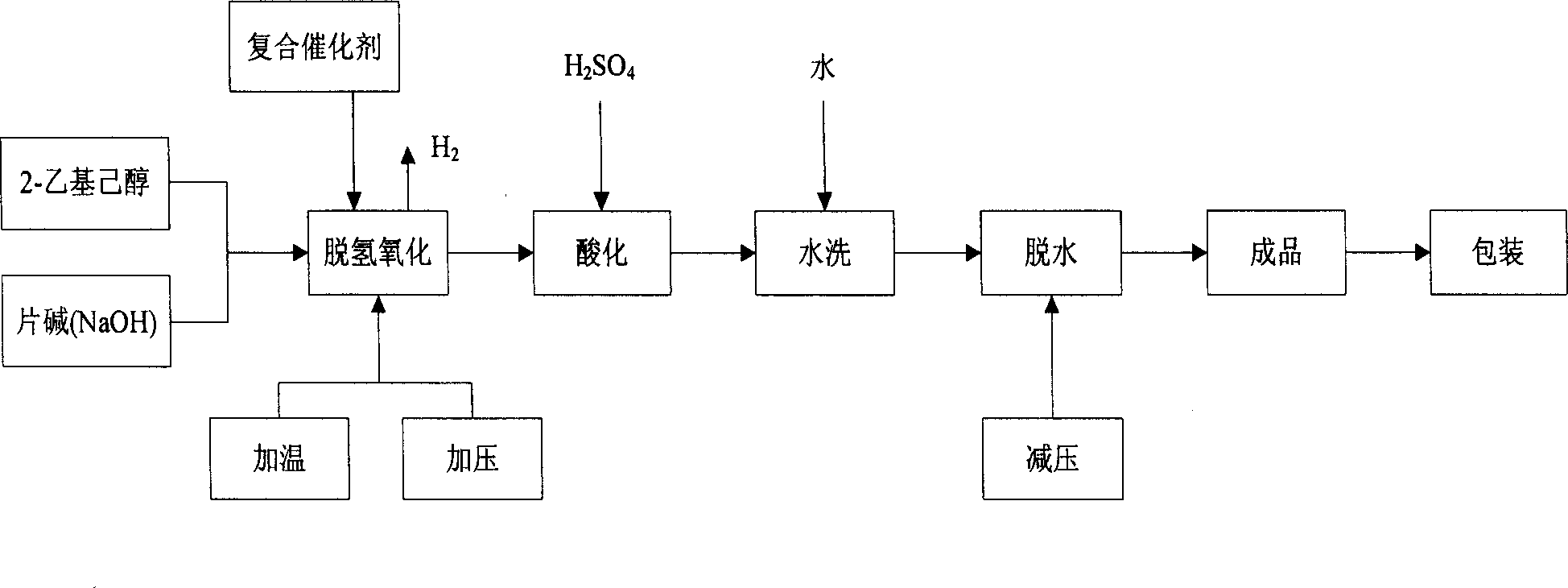

Production of isooctaacid by composite catalytic method

A technology of isooctanoic acid and a new process, which is applied in the direction of chemical instruments and methods, preparation of organic compounds, physical/chemical process catalysts, etc., can solve problems such as strict equipment requirements, large consumption of raw materials and energy, and increased product costs, and achieve shortening The effect of process time, material cost reduction and production efficiency improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

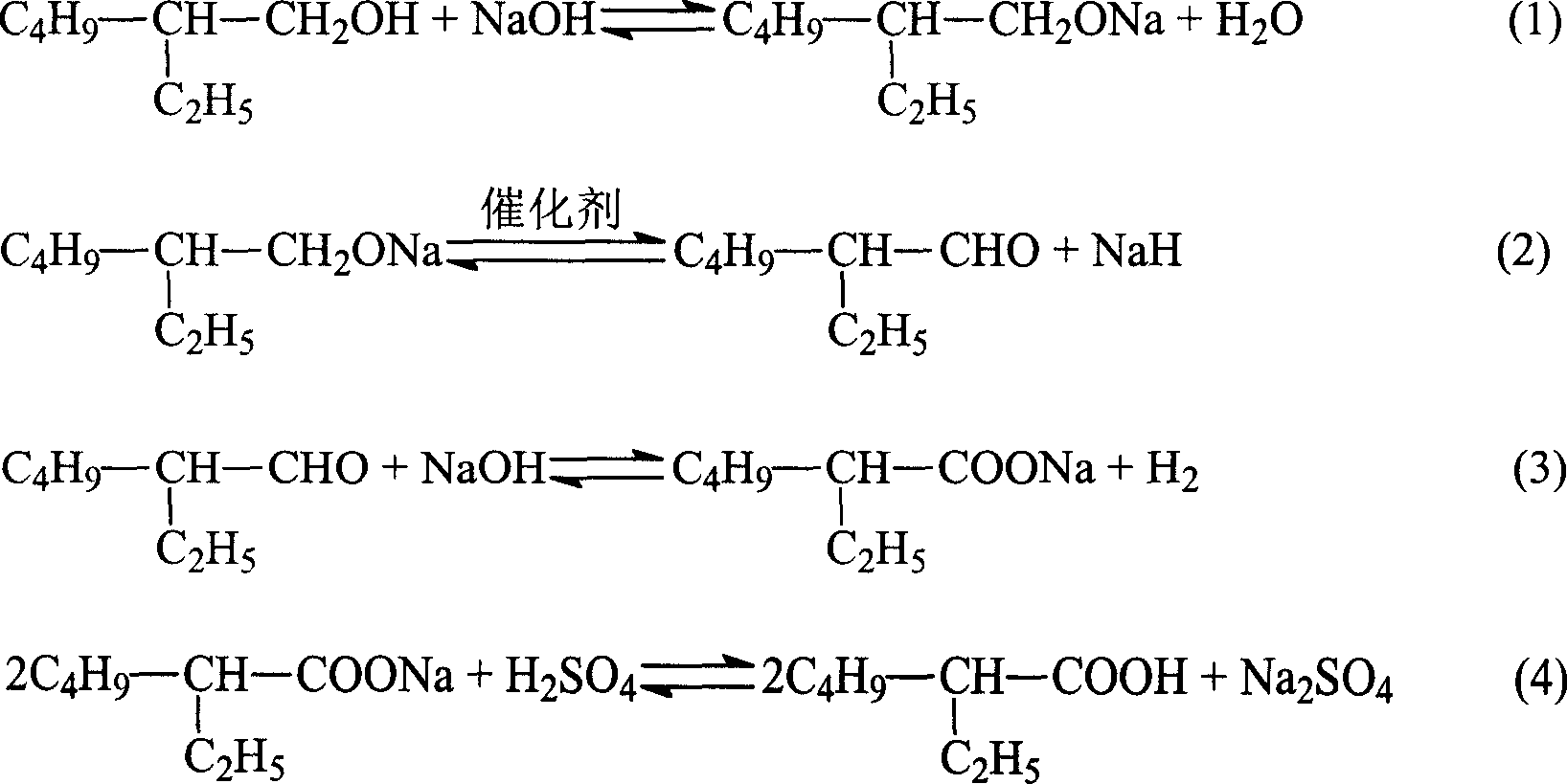

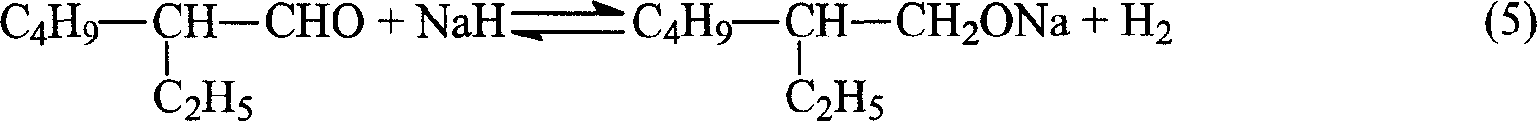

Method used

Image

Examples

Embodiment 1

[0037] Embodiment 1: at first iso-octanol 1000kg and concentration are that 379kg of sodium hydroxide aqueous solution 35% are packed in the reaction kettle that pressure is 4MPa, make alcohol-base molar ratio be 1.3; Calcium (purity 95%), 0.6 unit mass of vanadium pentoxide (purity 98.5%) and 0.1 unit mass of rare earth oxide (purity 99%) are combined; stirring and gradually heating to 260 ° C, making the alcohol alkali Oxidation reaction ends after 1.8 hours; Get rid of hydrogen; Then carry out cooling to reaction mass, add water 5% to dilute again, filter out the composite catalyst of solid; Then add content and be 35% H 2 SO 4 The pH of the material was brought to 3 by the aqueous solution, and the acidification reaction was carried out by stirring for 35 minutes, and the water layer was removed by stratification; then the material was washed with water; and dehydrated under reduced pressure to obtain 844 kg of iso-octanoic acid product and 211 kg of iso-octanol was recove...

Embodiment 2

[0039] At first iso-octanol and concentration are 40% sodium hydroxide aqueous solution packing pressure is in the reactor of 3MPa, make alcohol-alkali mol ratio be 1.2; Then add the calcium oxide (purity 95%) by 1.0 unit mass under stirring , 0.8 unit mass of vanadium pentoxide (purity 98.5%) and 0.2 unit mass of rare earth oxide (purity 99%) combined; stirring and gradually heating to 240 ° C, so that the alcohol-base oxidation reaction ends after 2 hours ; get rid of hydrogen; then cool the reaction mass, then dilute with 10% water, filter out the solid composite catalyst; then add 30% H 2 SO 4 The pH of the material was brought to 3 by the aqueous solution, and the acidification reaction was carried out by stirring for 30 minutes, and the water layer was removed by stratification; the material was washed with water; and dehydrated under reduced pressure to obtain 840 kg of iso-octanoic acid product, and 208 kg of iso-octanol was recovered. After inspection, acid value (mg...

Embodiment 3

[0041]At first iso-octanol and the concentration of 38% sodium hydroxide aqueous solution are packed into a reaction kettle with a pressure of 5 MPa, so that the alcohol-base molar ratio is 1.5; then add 1.2 units of calcium oxide (purity 95%) under stirring , 0.9 unit mass of vanadium pentoxide (purity 98.5%) and 0.4 unit mass of rare earth oxide (purity 99%) combined catalyst; stirring and gradually heating to 280 ° C, so that the alcohol-base oxidation reaction ends after 2.2 hours ; get rid of hydrogen; then carry out the cooling of reaction mass, add water 8% to dilute, filter out the composite catalyst of solid; then add content and be 40% H 2 SO 4 The pH of the material was brought to 3 by the aqueous solution, and the acidification reaction was carried out by stirring for 40 minutes, and the water layer was removed by stratification; the material was washed with water; and dehydrated under reduced pressure to obtain 845 kg of iso-octanoic acid product, and 107 kg of is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com