Preparation method of catalytic composite material Mn3O4/ZIF-8 (Zeolite Imidazate Framework-8) for activating PMS (Potassium Monopersulfate)

A technology of ZIF-8, zinc nitrate hexahydrate, used in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The concrete steps of this embodiment are as follows:

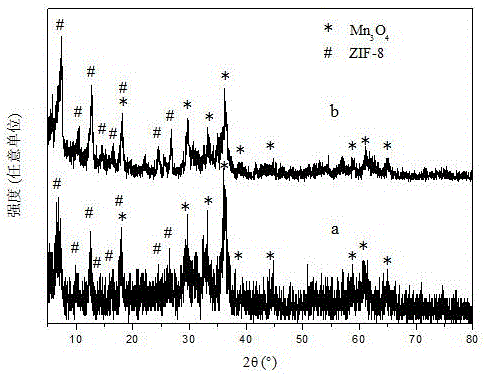

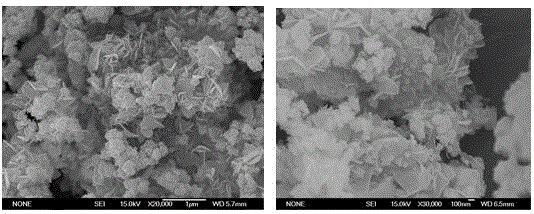

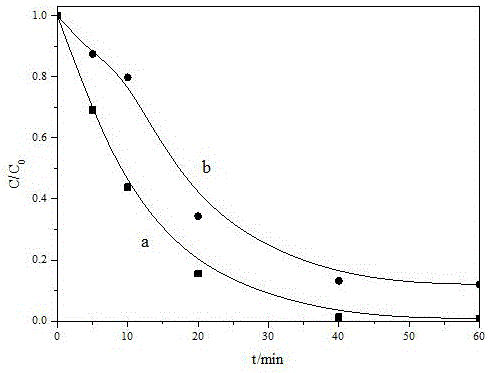

[0028] The catalytic composite material Mn of novel activation PMS of the present invention 3 o 4 The preparation method of / ZIF-8, this method is to be raw material with zinc nitrate hexahydrate, MIM, sodium formate dihydrate, DMF, potassium permanganate, adopts colloid chemical synthesis method and solvothermal method to prepare Mn 3 o 4 / ZIF-8 composite. Its technological process is: the Zn(NO of weighing 29.5 mmol 3 ) 2 •6H 2 Dissolve O in 50 mL of DMF and magnetically stir at room temperature until completely dissolved; weigh 88.4 mmol of HCOONa 2H 2 O and 117.9 mmol of MIM were dissolved in 25 mL of DMF, stirred magnetically at room temperature until uniformly dispersed; the two mixtures were mixed, stirred magnetically at room temperature for 4 hours until the reaction was complete, and washed by centrifugation, secondary water and anhydrous methanol After 5-6 times of drying at 60°C for 10 hours, the...

Embodiment 2

[0031] The concrete steps of this embodiment are as follows:

[0032] The catalytic composite material Mn of novel activation PMS of the present invention 3 o 4 The preparation method of / ZIF-8, this method is to be raw material with zinc nitrate hexahydrate, MIM, sodium formate dihydrate, DMF, potassium permanganate, adopts colloid chemical synthesis method and solvothermal method to prepare Mn 3 o 4 / ZIF-8 composite. Its technological process is: the Zn(NO of weighing 29.5 mmol 3 ) 2 •6H 2 Dissolve O in 50 mL of DMF and magnetically stir at room temperature until completely dissolved; weigh 88.4 mmol of HCOONa 2H 2 O and 117.9 mmol of MIM were dissolved in 25 mL of DMF, stirred magnetically at room temperature until uniformly dispersed; the two mixtures were mixed, stirred magnetically at room temperature for 4 hours until the reaction was complete, and centrifuged, secondary water and anhydrous methanol The product ZIF-8 was obtained after washing 5-6 times and dryin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com