Super-hydrophobic metal-organic framework array, as well as preparation method and application thereof

A metal-organic framework, super-hydrophobic technology, used in separation methods, chemical instruments and methods, liquid separation, etc., can solve the problem of less design of other structures, and achieve the effects of excellent hydrophobicity, high separation efficiency and reusability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

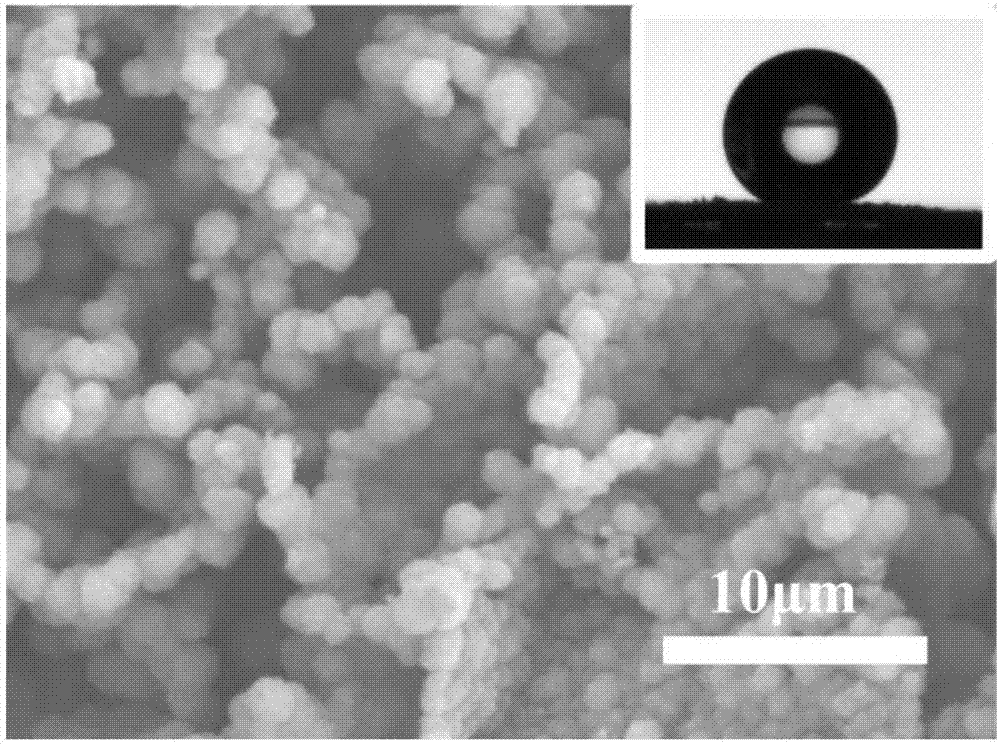

Embodiment 1

[0028] (1) Cut a stainless steel mesh with a size of 2cm×3cm×0.05cm, put it in 12mL acetone, ultrasonically clean it for 30s, and dry it at 80°C for later use;

[0029] (2) Weigh 0.89g of zinc nitrate hexahydrate, 0.45g of 2-methylimidazole, and 0.235g of anhydrous sodium formate, dissolve them in 25mL of ethanol, and ultrasonicate for 10min; place the clean stainless steel mesh obtained in step (1) vertically in a Put the solution in a polytetrafluoroethylene reactor; react at 90°C for 10 hours to obtain a ZnO array; place the ZnO array in ethanol for 15 seconds to remove excess ZnO on the surface, dry it at room temperature, and set aside;

[0030] (3) Weigh 0.40g of benzimidazole and dissolve it in 30mL of N,N-dimethylformamide, and ultrasonicate for 2min until the solution is completely clear; place the ZnO array obtained in step (2) vertically in a In a polytetrafluoroethylene reactor; react at 130°C for 10 hours to obtain a ZIF-7 array; wash the ZIF-7 array with N,N-dime...

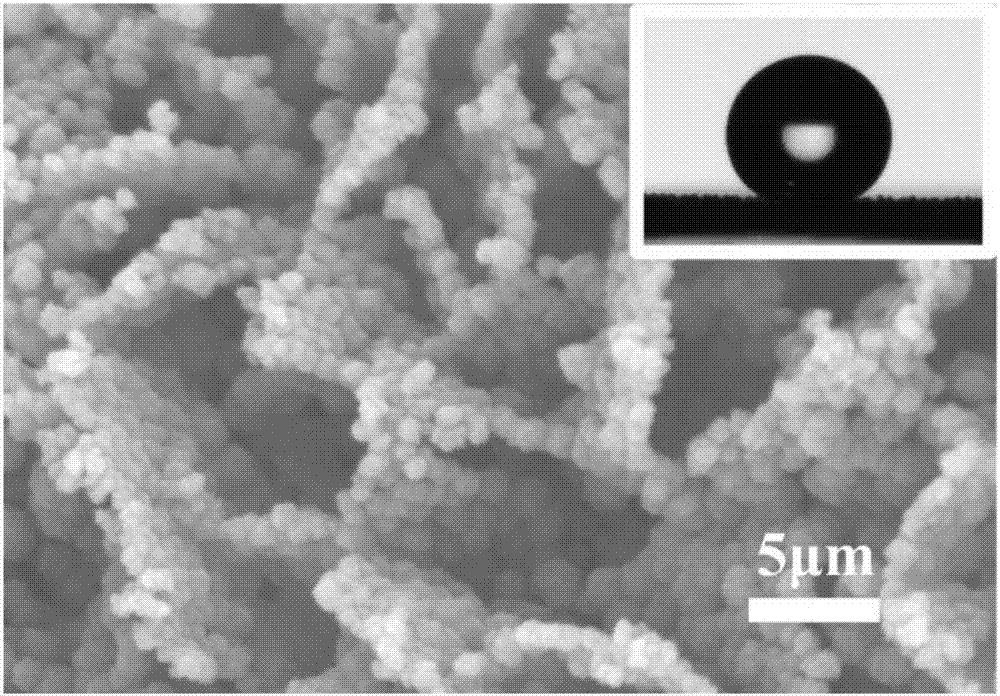

Embodiment 2

[0033] (1) Cut a ceramic membrane with a size of 2cm×3cm×0.1cm, place it in 20mL acetone for ultrasonic cleaning for 30s, and dry it at 80°C for later use;

[0034] (2) Weigh 0.89g of zinc nitrate hexahydrate, 0.45g of 2-methylimidazole, and 0.235g of anhydrous sodium formate and dissolve them in 25mL of ethanol, and ultrasonicate for 10min; place the clean ceramic membrane obtained in step (1) vertically in a Put the clarified solution in a polytetrafluoroethylene reactor; react at 90°C for 10 hours to obtain a ZnO array; put the ZnO array in ethanol and ultrasonically remove excess ZnO on the surface for 15 seconds, dry it at room temperature, and set aside;

[0035] (3) Weigh 0.40g of benzimidazole and dissolve it in 30mL of N,N-dimethylformamide, and ultrasonicate for 2min until the solution is completely clear; place the ZnO array obtained in step (2) vertically in a In a polytetrafluoroethylene reactor; react at 130°C for 10 hours to obtain a ZIF-7 array; wash the ZIF-7 ...

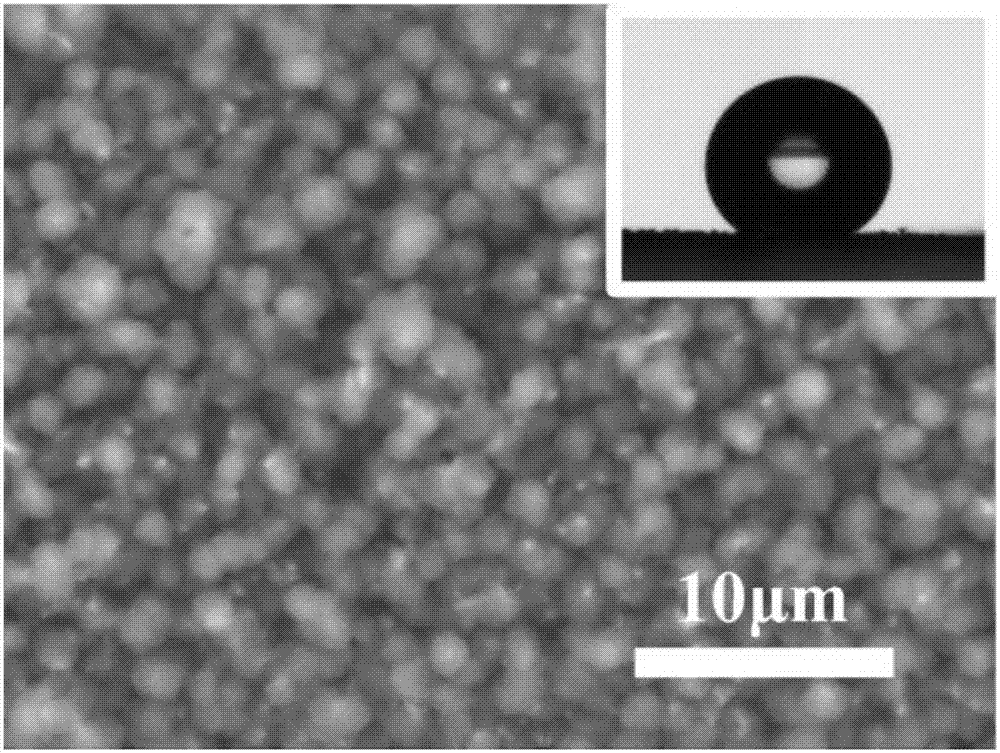

Embodiment 3

[0038] (1) Cut a stainless steel mesh with a size of 2cm×3cm×0.05cm, put it in 12mL acetone, ultrasonically clean it for 30s, and dry it at 80°C for later use;

[0039] (2) Weigh 0.625g of zinc nitrate hexahydrate, 0.25g of 2-methylimidazole, and 0.125g of anhydrous sodium formate, dissolve them in 35mL of ethanol, and ultrasonicate for 10min; place the clean stainless steel mesh obtained in step (1) vertically in a Put the solution in a polytetrafluoroethylene reactor; react at 150°C for 10 hours to obtain a ZnO array; place the ZnO array in ethanol for 15 seconds to remove excess ZnO on the surface, dry it at room temperature, and set aside;

[0040](3) Weigh 0.60g of benzimidazole and dissolve it in 36mL of N,N-dimethylformamide, and ultrasonicate for 2min until the solution is completely clear; place the ZnO array obtained in step (2) vertically on the In a polytetrafluoroethylene reactor; react at 140°C for 10 hours to obtain a ZIF-7 array; wash the ZIF-7 array with N,N-d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Water static contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com