Method for recycling sodium formate and sodium sulfite from waste sodium hydrosulfite liquid with sodium formate method

A recovery method and sodium sulfite technology are applied in the preparation of alkali metal sulfites, chemical instruments and methods, separation/purification of carboxylic acid compounds, etc., which can solve problems such as material waste and environmental pollution, and achieve simple process and high purity. , easy to achieve effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

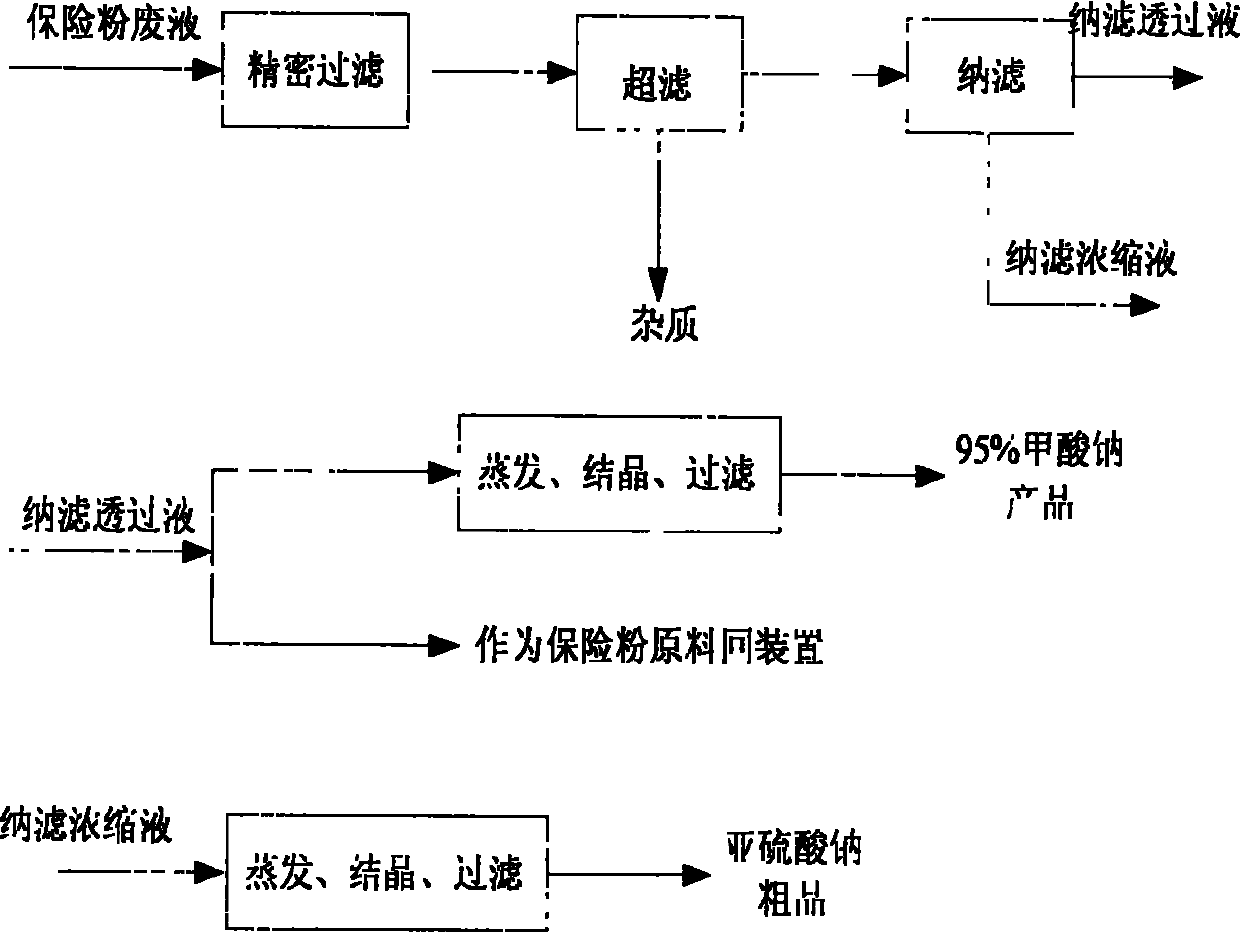

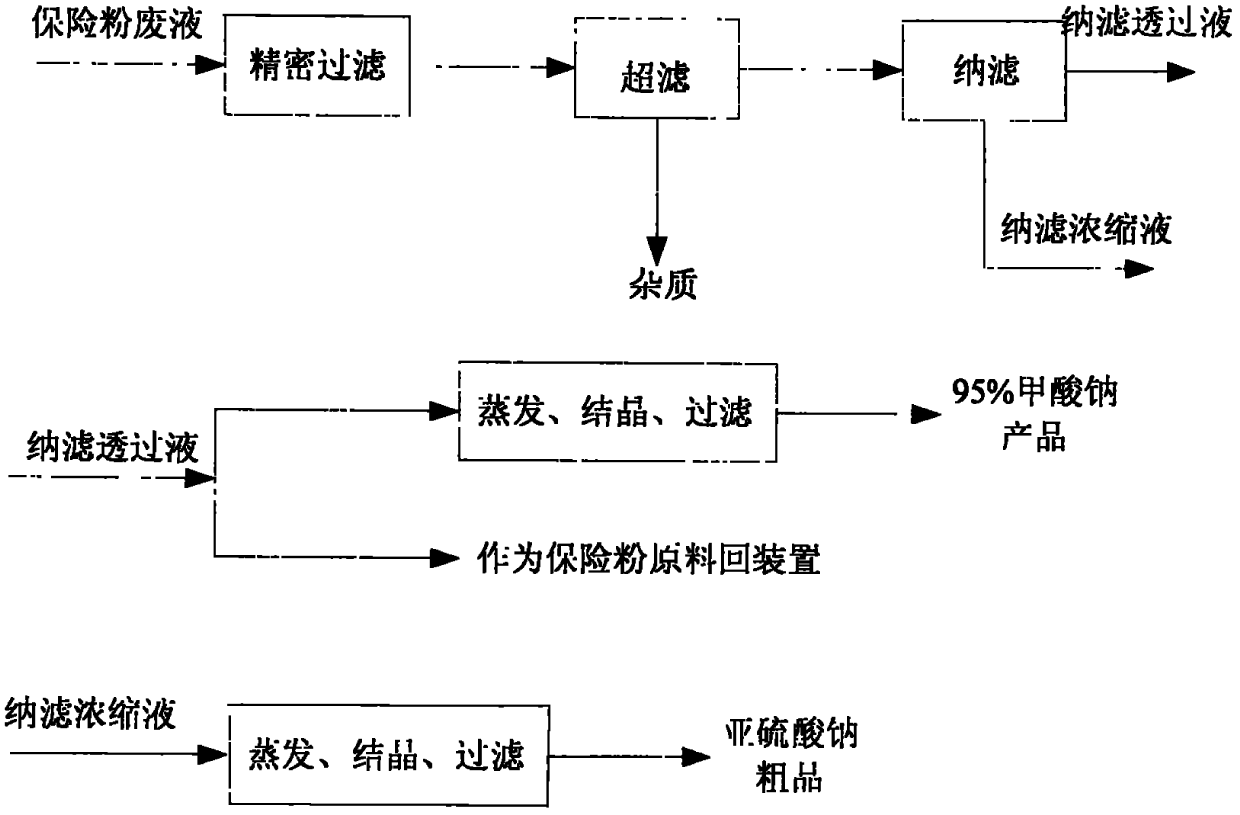

[0022] The recovery method of sodium formate and sodium sulfite in the sodium formate method hydrosulfite waste liquid of embodiment 1 comprises the following steps:

[0023] (1) Sodium formate method hydrosulfite waste liquid is firstly filtered through a precision filter and an ultrafiltration device to remove particulate impurities; the molecular weight cut-off of the ultrafiltration membrane of the ultrafiltration device is 5000, and the ultrafiltration temperature is 20°C.

[0024] (2) The waste liquid after removing particulate impurities enters the nanofiltration system for nanofiltration separation; the nanofiltration membrane of the nanofiltration system has a molecular weight cut-off of 150-300, an operating temperature of 20° C., and an operating pressure of 4.0 MPa.

[0025] (3) the nanofiltration permeate liquid returns to the sodium formate production section as the raw material of sodium hydrosulfite or through evaporation, crystallization, filtration, obtains th...

Embodiment 2

[0027] Example 2 The recovery method of sodium formate and sodium sulfite in the sodium formate method hydrosulfite waste liquid, the steps are the same as in Example 1, but the ultrafiltration temperature in the step (1) is 50°C; the operating temperature in the step (2) is 50°C °C, the operating pressure is 1.0MPa.

Embodiment 3

[0028] Example 3 The recovery method of sodium formate and sodium sulfite in the sodium formate method hydrosulfite waste liquid, the steps are the same as in Example 1, but the molecular weight cut-off of the ultrafiltration membrane of the ultrafiltration device in the step (1) is 10000, and the ultrafiltration temperature is 40 ° C; The operating temperature of the step (2) is 40° C., and the operating pressure is 2.0 MPa.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com