Zeolite imidazate framework/polyamide composite membrane and preparation method thereof

A technology of zeolite imidazolate and polyamide, applied in separation methods, chemical instruments and methods, membrane technology, etc., can solve problems such as poor compatibility and uneven distribution of MOFs, and achieve improved gas separation performance, great development potential and industrial application Foreground, the effect of simple film making process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

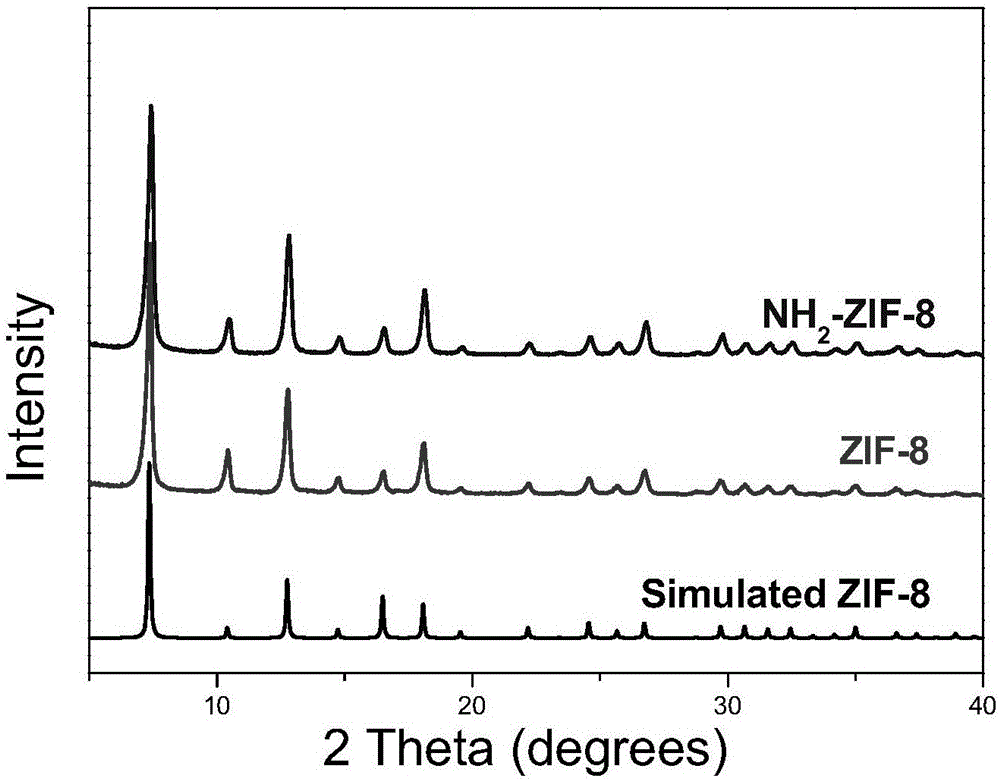

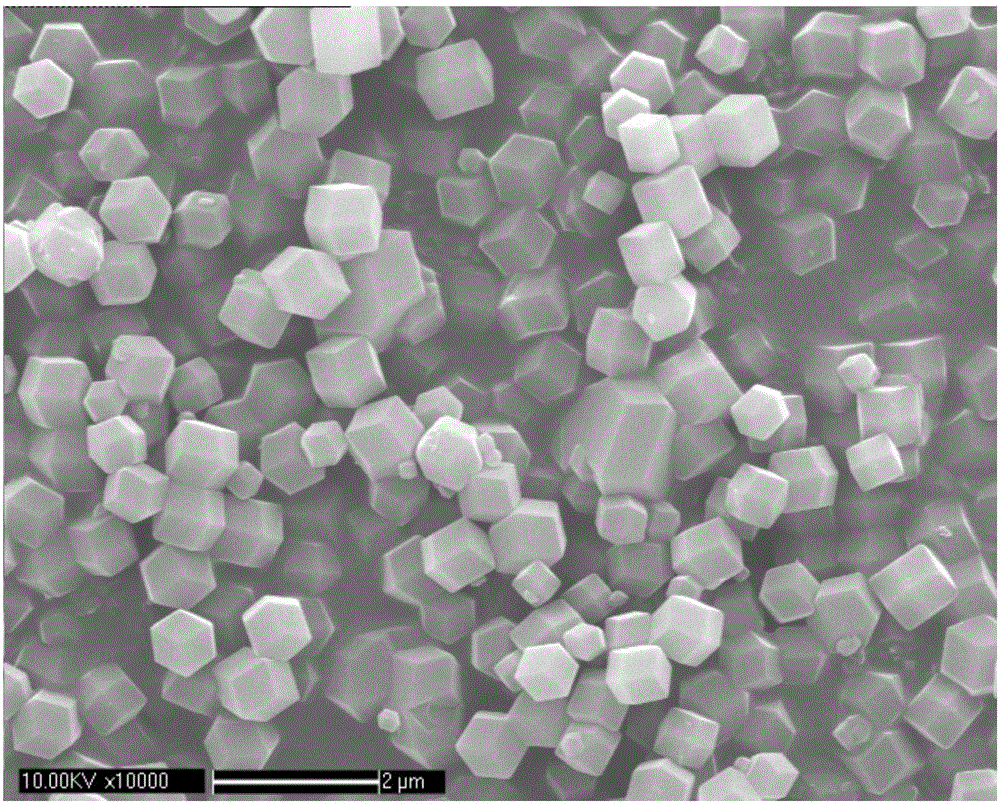

[0036] Step 1: first dissolve two kinds of imidazoles of sodium formate 20mmol, 2-aminobenzimidazole 12mmol and 2-methylimidazole in total 68mmol in deionized water 200ml; dissolve zinc nitrate hexahydrate 20mmol in N,N-dimethylformaldehyde In 200ml of amide; the two solutions were mixed and reacted for 1h, and NH was obtained by centrifugation, washing and drying 2 -ZIF-8 nanocrystalline material, its XRD pattern and SEM pattern are detailed figure 1 and figure 2 .

[0037] Step 2: Put 0.3g NH 2 -ZIF-8 nanocrystalline material was dispersed in 100ml deionized water by ultrasonic, ultrasonic dispersion time was 3h; then 0.4g Na was added in turn 2 CO 3 and 0.5ml of DNMDAm, stirred until completely dissolved to obtain an aqueous solution; 0.3ml of trimesoyl chloride (TMC) was dissolved in 100ml of n-hexane, and stirred until completely dissolved to obtain an organic solution.

[0038] Step 3: Pour the organic phase solution obtained in Step 2 onto the silicone rubber memb...

Embodiment 2

[0051] Step 1: first dissolve two kinds of imidazoles of sodium formate 20mmol, 2-aminobenzimidazole 12mmol and 2-methylimidazole in total 68mmol in deionized water 200ml; dissolve zinc nitrate hexahydrate 20mmol in N,N-dimethylformaldehyde In 200ml of amide; the two solutions were mixed and reacted for 1h, and NH was obtained by centrifugation, washing and drying 2 - ZIF-8 nanocrystalline material.

[0052] Step 2: Combine 0.6g, 1g and 2g NH 2 -ZIF-8 nanocrystalline materials were dispersed in three parts of 100ml deionized water by ultrasonic respectively, the ultrasonic dispersion time was 3h; then 0.4g Na was added in turn 2 CO 3 and 0.5ml of DNMDAm into three parts of aqueous solutions, stirred until completely dissolved to obtain an aqueous solution; 0.3ml of trimesoyl chloride (TMC) was dissolved in 100ml of n-hexane, stirred until completely dissolved, to obtain an organic solution, and prepared 3 copies.

[0053] Step 3: Pour the three organic phase solutions obta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com