Synthesis method of taurine

A synthetic method, the technology of taurine, applied in the direction of sulfonic acid preparation, organic chemistry, etc., can solve the problems of difficult control, cumbersome process, expensive raw material cost, etc., and achieve the effect of less reaction steps and concise process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

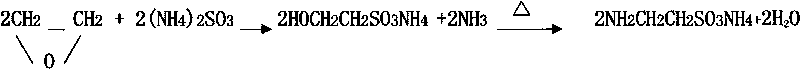

Method used

Image

Examples

Embodiment 1

[0012] Put 200 kilograms of water in a 1000-liter stainless steel high-pressure reactor with stirring, heating and devices, and add 145 kilograms of ammonium sulfite (80.0%) (1×10 3 mol), 44 kg (1.0×10 3 mol), then seal and heat, stir until the temperature in the kettle is 150°C to 160°C, and maintain the pressure in the kettle at 0.5-1MPa, and continue to react in between for 5 hours to obtain ammonium taurine salt solution, and lower the temperature while stirring When the temperature is below 50°C, add 50% sulfuric acid to adjust the pH value of the material in the kettle to be ≤7, and centrifuge to obtain 130 kg of crude taurine;

[0013] Put 130 kilograms of the above-mentioned crude product taurine into a 500L reaction kettle, add 200L of water and 0.1 kilogram of activated carbon, dissolve the crude product taurine under heating and stirring, filter and remove the activated carbon to obtain a colorless transparent liquid, and cool down to 5 DEG C, centrifuge and wash t...

Embodiment 2

[0019] Put 200 grams of water in a 1000 milliliter four-necked flask with stirring, heating and devices, and add 290 grams (2mol) of ammonium sulfite (80.0%), and feed 44 grams of ethylene oxide (99.9%) under stirring (1mol), then water-sealed and heated, stirred until the temperature in the kettle was 100°C to 115°C, and the pressure in the flask was maintained at normal pressure for 5 hours to obtain ammonium taurine salt solution, and the temperature was lowered to below 50°C while stirring , adding 50% sulfuric acid to adjust the pH value of the material in the kettle to be less than or equal to 7, and centrifuged to obtain 121 grams of crude product taurine;

[0020] Put 121 grams of the above-mentioned crude product taurine into a 500 milliliter four-neck flask with stirring, heating and devices, add 200 grams of water and 0.1 gram of activated carbon, dissolve the crude product taurine under heating and stirring, and remove the activated carbon by filtration to obtain c...

Embodiment 3

[0022] Put 200 grams of water in a 1000 milliliter four-necked flask with stirring, heating and devices, and add 145 grams (1mol) of ammonium sulfite (80.0%), and feed 88 grams of ethylene oxide (99.9%) under stirring (2mol), then water-sealed and heated, stirred until the temperature in the bottle was 105°C to 100°C, and reacted under normal pressure for 5 hours to obtain a taurine ammonium salt solution, which was cooled to below 50°C while stirring, and 30% sulfuric acid was added to adjust The pH value of the material in the kettle was ≤7, and it was centrifuged to obtain 129 grams of crude taurine;

[0023] Put 129 grams of the above-mentioned crude product taurine into a 500 milliliter four-neck flask with stirring, heating and devices, add 200 grams of water and 0.1 gram of activated carbon, dissolve the crude product taurine under heating and stirring, and remove the activated carbon by filtration to obtain color transparent liquid, cooled to 5°C under stirring, centri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com