Method used for producing sulfur-based urea compound fertilizer from ammonia desulphurization by-products

A technology of ammonia desulfurization and compound fertilizer, which is applied in the field of producing sulfur-based urea compound fertilizer, can solve the problems of poor product quality, high energy consumption, and large steam consumption, and achieve the effects of low cost, low energy consumption, and low desulfurization cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

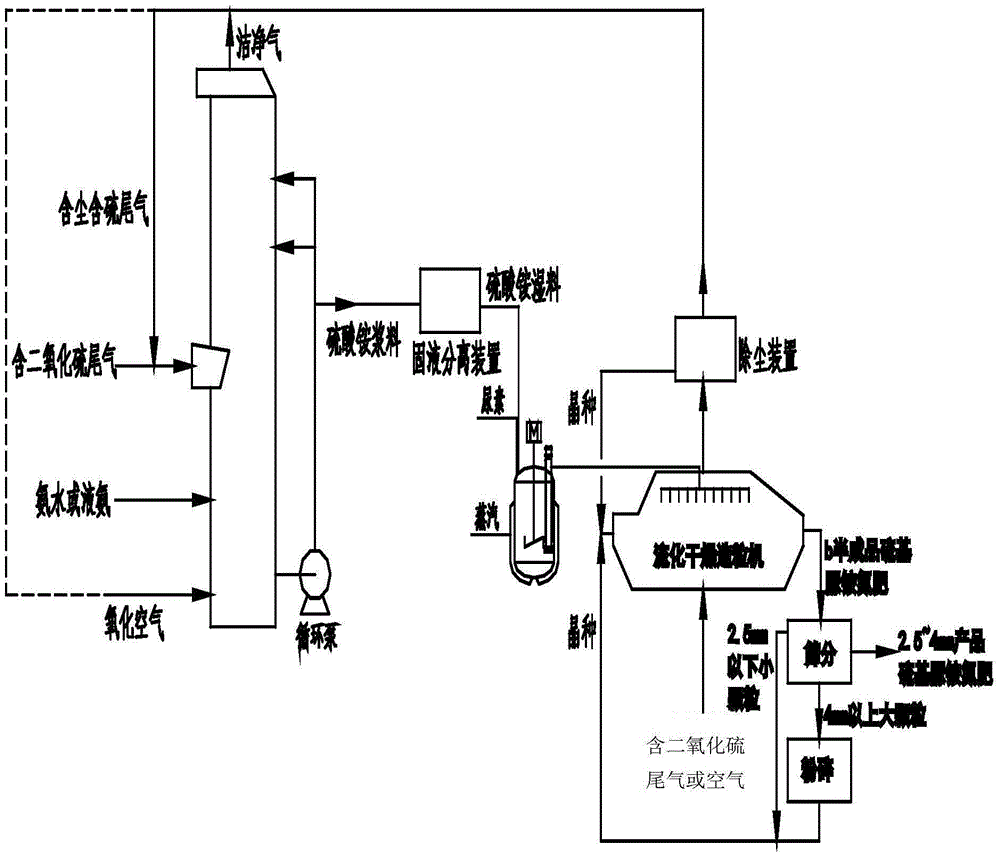

[0033] 20000Nm 3 / h150℃, 5kPa, sulfur dioxide concentration 1000mg / Nm 3 of sulfur dioxide-containing tail gas, of which 19000Nm 3 / h directly enters the DN2400*35000 desulfurization tower, uses 15% ammonia water as the desulfurizer, and the concentration of sulfur dioxide in the clean gas after desulfurization is 20mg / Nm 3, after absorption, oxidation, concentration, solid-liquid separation (using centrifuge), 21kg / h wet material ammonium sulfate (water content 5%) is obtained and added to the molten urea tank, and raw material urea (nitrogen content 46.4%) is fed at a speed of 22kg / h Add the molten urea tank, the molten urea tank is equipped with a jacket, heated with 0.4MPa steam, and the temperature of the solution is controlled at 115-118°C. The molten urea tank is equipped with a stirrer. After fully mixed, pump into the fluidized bed, another 1000Nm 3 / h The tail gas containing sulfur dioxide is also passed into the fluidized bed, and the mixed solution is fluidized,...

Embodiment 2

[0035] 30000Nm 3 / h151℃, 6.6kPa, sulfur dioxide concentration 2000mg / Nm 3 of sulfur dioxide-containing tail gas, of which 26000Nm 3 / h directly enters the DN3000*36000 desulfurization tower, uses 25% ammonia water as the desulfurizer, and the concentration of sulfur dioxide in the clean gas after desulfurization is 23mg / Nm 3 After absorption, oxidation, concentration, and solid-liquid separation (using a plate and frame filter), 63kg / h of wet material ammonium sulfate (water content 5%) is obtained and added to the molten urea tank. The molten urea tank is equipped with a jacket and heated with 0.3MPa steam. Control the solution temperature to 112-115°C. The molten urea tank is equipped with a stirrer. At the same time, the raw material urea (46.4% nitrogen content) is added to the molten urea tank at a rate of 200kg / h, and after being fully mixed, it is pumped into the fluidized bed, and another 4000Nm 3 / h The tail gas containing sulfur dioxide is also passed into the fl...

Embodiment 3

[0037] 30000Nm 3 / h145℃, 2.6kPa, sulfur dioxide concentration 3000mg / Nm 3 The sulfur dioxide-containing tail gas directly enters the DN3200*36000 desulfurization tower, using liquid ammonia as the desulfurizer, and the concentration of sulfur dioxide in the clean gas after desulfurization is 29.8mg / Nm 3 , absorb, oxidize, concentrate, solid-liquid separation (drum filtration) to obtain 94kg / h wet material ammonium sulfate (water content 4.75%) into the molten urea tank, while the raw material urea (nitrogen content 46.4%) at a speed of 180kg / h Add molten urea to the tank, set a jacket on the molten urea tank, heat with 0.3MPa steam, and control the solution temperature to 111-114°C. The molten urea tank is equipped with a stirrer. After fully mixed, pump into the fluidized bed, another 2000Nm 3 / h, 152°C air is also passed into the fluidized bed, and the mixed solution is fluidized, dried and granulated. Gradually increase from import to export. The gas discharged from t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com