Method for controlling aerosol generation in absorbing process by ammonia process of desulfurization

An absorption process, ammonia desulfurization technology, applied in the field of environmental protection, can solve the problems of high operating cost, low concentration of absorption liquid, and less crystallization, and achieve the effects of reducing energy consumption, reducing ammonia escape, and avoiding waste water discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

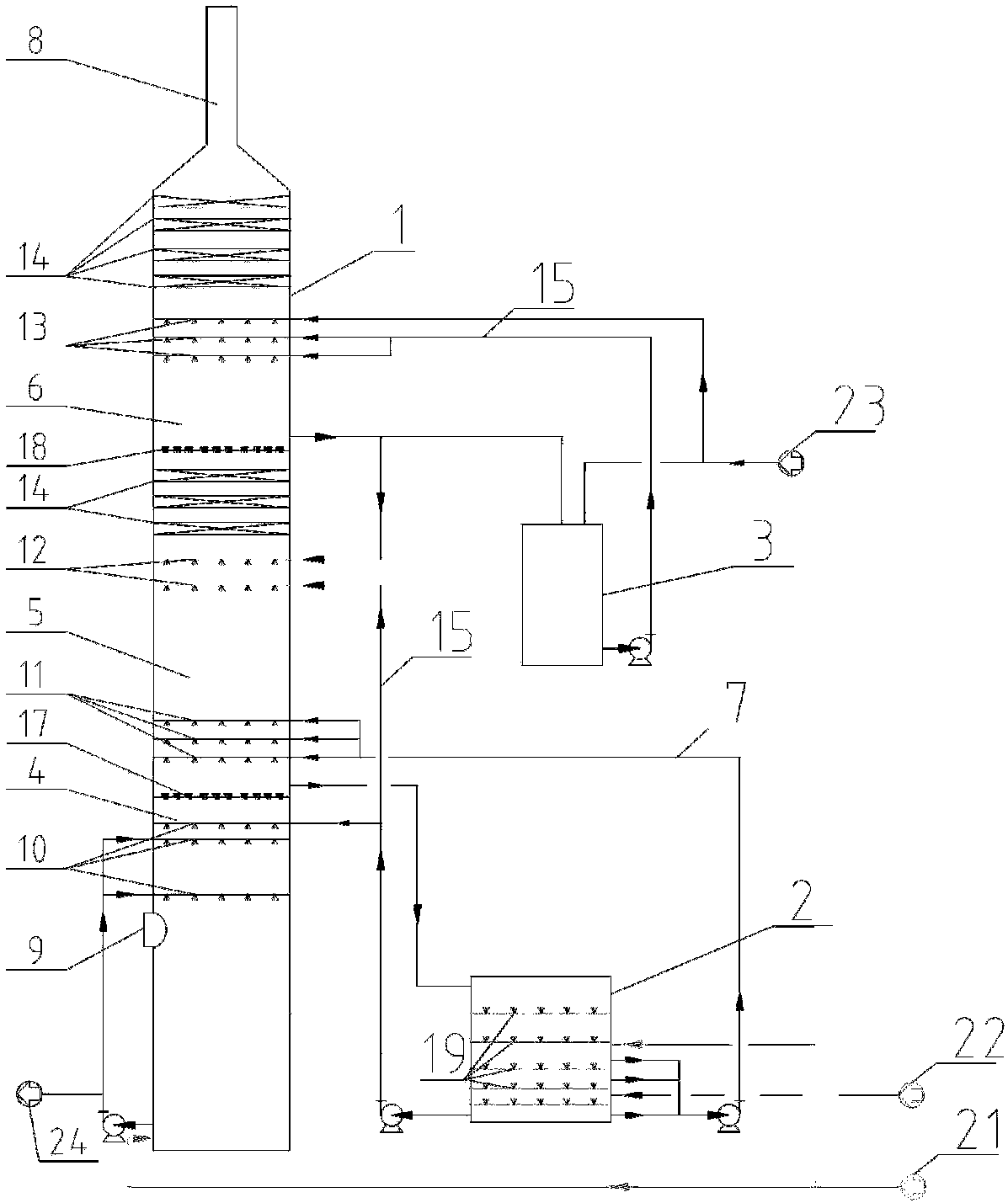

[0144] like figure 1 The method for controlling aerosol generation in the absorption process of ammonia desulfurization, uses the absorption circulation liquid containing ammonium sulfite to remove sulfur dioxide in the flue gas, so as to control the generation of aerosol in the absorption process of ammonia desulfurization.

[0145] Through graded solution composition control and reaction condition control, high-efficiency desulfurization and dust removal are realized, and ammonia escape and aerosol generation are controlled while desulfurization is efficient.

[0146] The graded solution component control includes concentration gradient control of ammonium sulfite, ammonium bisulfite, ammonium sulfate or a combination thereof.

[0147] The flue gas enters from the pre-washing area, and the flue gas after preliminary cooling and purification in the pre-washing area contacts with the absorption circulation liquid 7 and the fine particle circulation washing liquid 15 in order t...

Embodiment 1

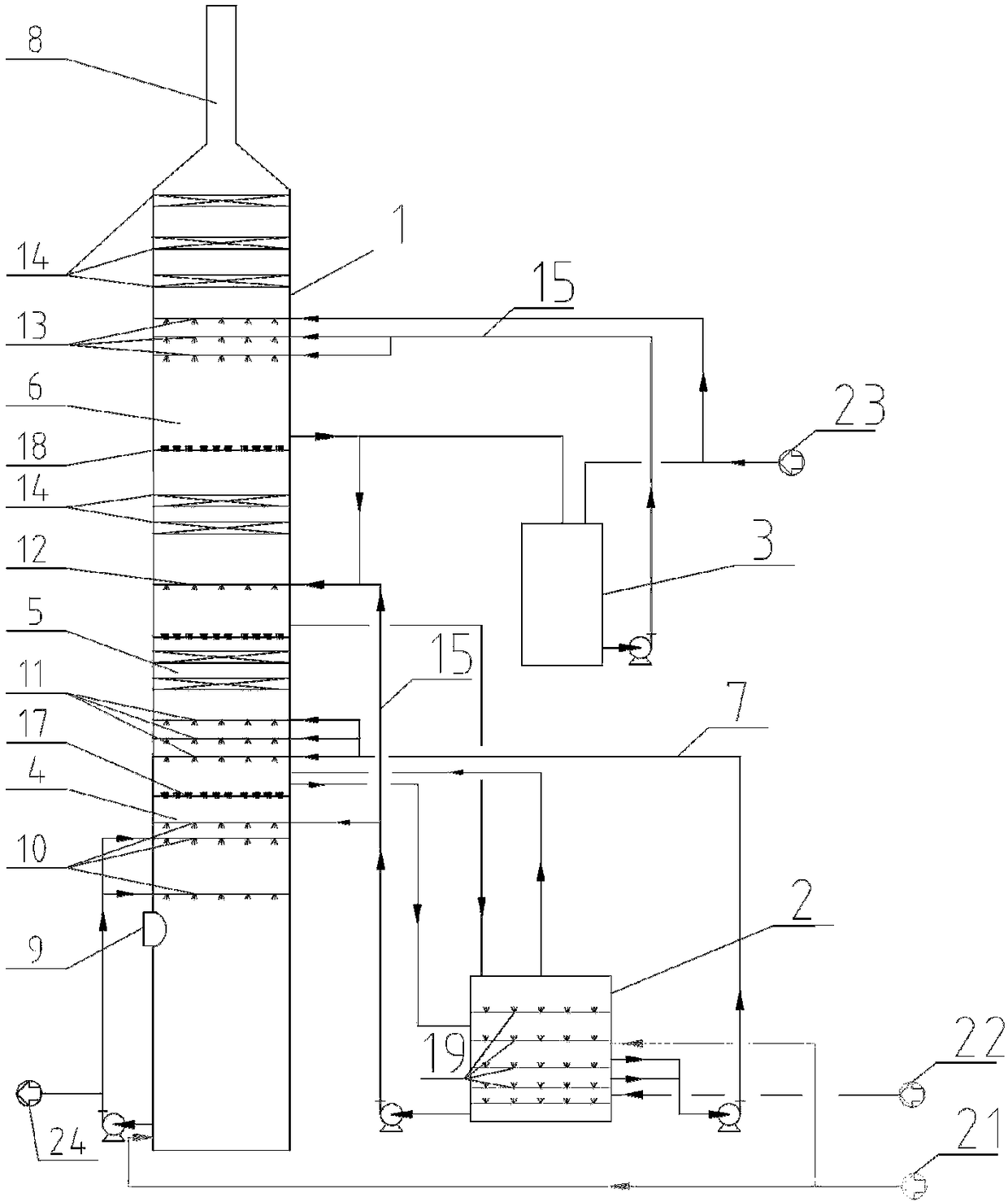

[0168] 1. A method for ammonia desulfurization to control aerosol generation in the absorption process

[0169] The sulfur dioxide in the flue gas is removed by the absorption circulation liquid containing ammonium sulfite to control the generation of aerosol in the absorption process of ammonia desulfurization.

[0170] Through graded solution composition control and reaction condition control, high-efficiency desulfurization and dust removal are realized, and ammonia escape and aerosol generation are controlled while desulfurization is efficient.

[0171] The graded solution component control includes concentration gradient control of ammonium sulfite, ammonium bisulfite, ammonium sulfate or a combination thereof.

[0172] The flue gas enters from the pre-washing area of the absorption tower, and the pre-cooled and purified flue gas in the pre-washing area contacts the absorption circulating liquid 7 and the fine particle washing circulating liquid 15 in order to realize t...

Embodiment 2

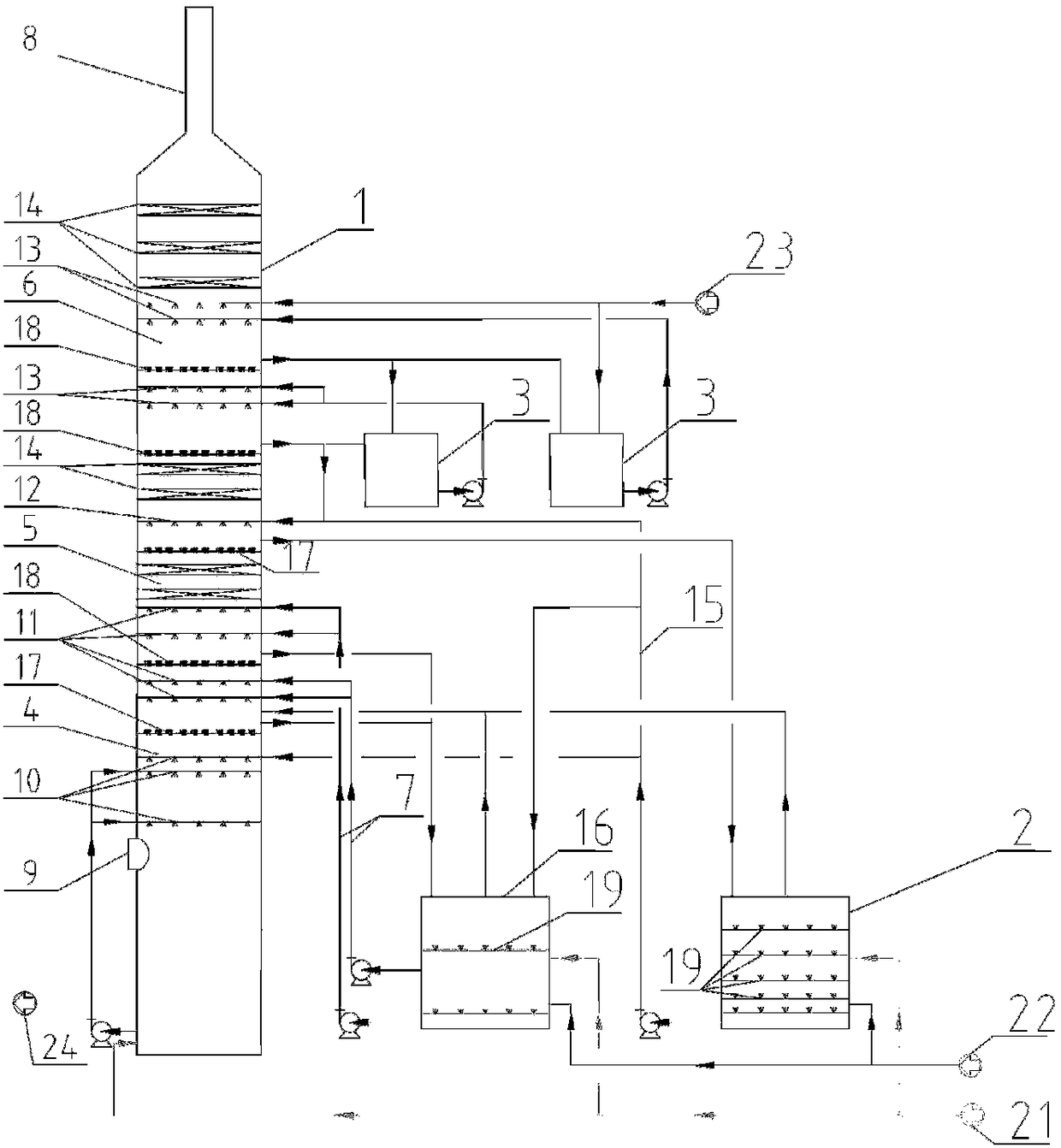

[0205] 1. A method for ammonia desulfurization to control aerosol generation in the absorption process

[0206] The sulfur dioxide in the flue gas is removed by the absorption circulation liquid containing ammonium sulfite to control the generation of aerosol in the absorption process of ammonia desulfurization.

[0207] Through graded solution composition control and reaction condition control, high-efficiency desulfurization and dust removal are realized, and ammonia escape and aerosol generation are controlled while desulfurization is efficient.

[0208] The graded solution component control includes concentration gradient control of ammonium sulfite, ammonium bisulfite, ammonium sulfate or a combination thereof.

[0209] The flue gas enters from the pre-washing area, and the flue gas after preliminary cooling and purification in the pre-washing area contacts with the absorption circulation liquid 7 and the fine particle washing circulation liquid 15 in order to realize the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com