Polyethylene powder, composition, cross-linked polyethylene pipe and preparation methods of polyethylene powder and cross-linked polyethylene pipe

A technology for polyethylene powder and compound is applied in the fields of composition, polyethylene powder, cross-linked polyethylene pipe and preparation, and can solve the problems of uneven particle size distribution of polyethylene powder, high cost and complicated preparation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

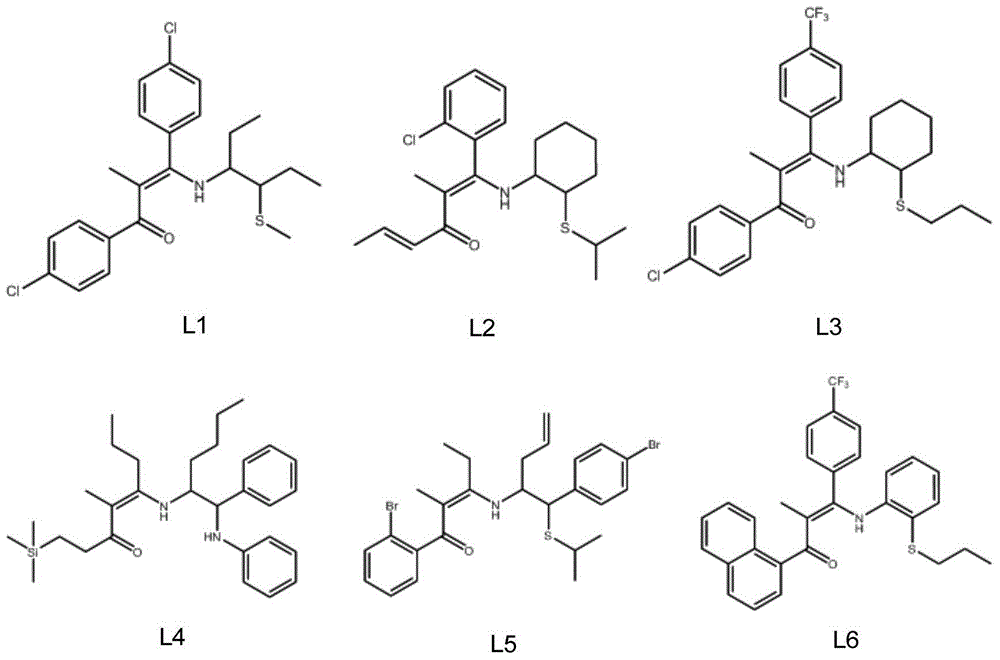

[0101] Weigh 2g of anhydrous magnesium chloride and 2.77g of L29 multidentate ligand under a nitrogen atmosphere, add 25mL of tetrahydrofuran, start stirring and control the temperature of the oil bath at 80°C to reflux for 2 hours to form a clear and transparent solution system, then add 1.34mL tetrahydrofuran dropwise within 10min Titanium chloride, continue to reflux for 2 hours after the dropwise addition.

[0102]

[0103] After cooling the above solution to room temperature, add 50 mL of n-hexane to precipitate, filter, then add 50 mL of n-hexane to wash, stir and mix for 30 minutes, then filter, add 50 mL of hexane again to wash, stir and mix for 30 minutes, and then filter. The filter cake was vacuum-dried at 80 °C for 5 h to constant weight.

[0104] Among them, the molar ratio of anhydrous magnesium chloride and multidentate ligand is 2:1, the molar ratio of titanium tetrachloride and multidentate ligand is 1.15:1, the volume ratio of precipitant n-hexane and tetr...

Embodiment 2

[0107] Except following conditions, other is all identical with embodiment 1:

[0108] The magnesium compound is selected from anhydrous magnesium bromide;

[0109] The multidentate ligand is L21.

[0110]

[0111] Among them, the molar ratio of anhydrous magnesium bromide and multidentate ligand is 2:1, the molar ratio of titanium tetrachloride and multidentate ligand is 1.15:1, and the volume ratio of precipitant hexane and tetrahydrofuran is 2:1 , the volume ratio of the washing solvent hexane and tetrahydrofuran is 2:1.

[0112] The catalyst is designated as CAT-2, Ti content: 7.9 wt%.

Embodiment 3

[0114] Except following conditions, other is all identical with embodiment 1:

[0115] The magnesium compound is selected from methoxymagnesium chloride (Mg(OCH 3 )Cl);

[0116] The multidentate ligand is L20.

[0117]

[0118] Among them, methoxymagnesium chloride (Mg(OCH 3 )Cl) and the molar ratio of the multidentate ligand is 2:1, the molar ratio of titanium tetrachloride and the multidentate ligand is 1.15:1, the volume ratio of the precipitating agent hexane and tetrahydrofuran is 2:1, and the washing solvent has The volume ratio of alkanes and tetrahydrofuran is 2:1.

[0119] The catalyst is designated as CAT-3, Ti content: 8.4 wt%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile yield stress | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Rockwell hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com