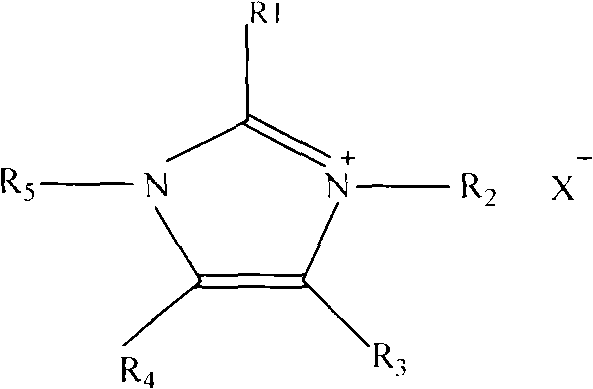

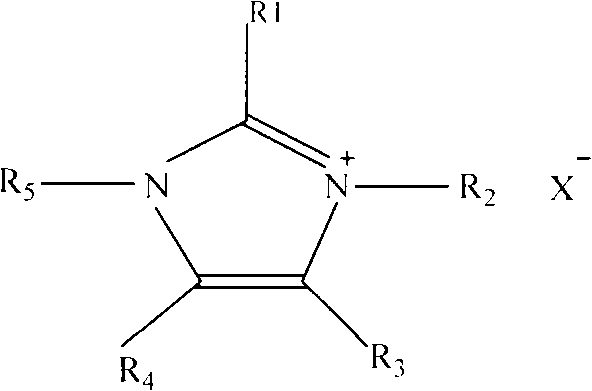

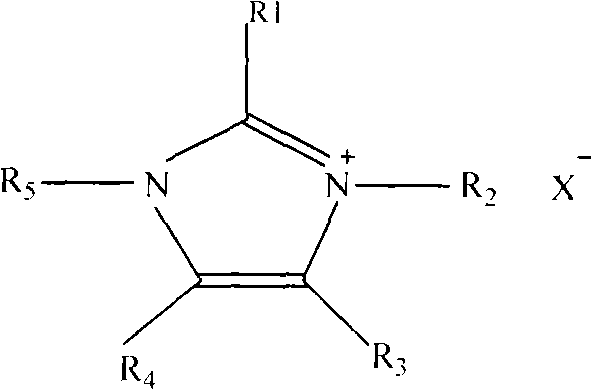

Method for preparing polyacrylonitrile spinning solution for high-performance carbon fiber in ionic liquid

A polyacrylonitrile spinning, ionic liquid technology, applied in the chemical characteristics of fibers, textiles and papermaking, bulk chemical production, etc. Wide range of speed, melting point, and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] At room temperature, acrylonitrile monomer, itaconic acid monomer and ionic liquid 1-butyl-3-methylimidazolium tetrafluoroborate were stirred to make them fully Mix and dissolve, then add a small amount of initiator AIBN, and pass nitrogen protection into the polymerization kettle. The temperature was raised to 58° C. for 4 hours, and the reaction conversion rate of the polymer was measured to be 65%.

[0041] Coagulate the polymer with normal temperature water whose volume is 5 times the volume of the reaction solution, wash 4 times with water at a temperature of 70°C and 3 times the mass of the solid matter, and vacuum dry at 65°C to constant weight. The viscosity-average molecular weight of the prepared polyacrylonitrile measured is 8.0×10 4 , the molecular weight distribution is 1.4.

[0042] Then use dimethyl sulfoxide as a solvent, the dissolution temperature is 65°C, the concentration of sulfoxide is 75%, the concentration of polyacrylonitrile powder is 25%, th...

Embodiment 2

[0044] At room temperature, stir the acrylonitrile monomer, itaconic acid monomer and ionic liquid 1-butyl-3-methylimidazolium hexafluorophosphate according to the mass fraction ratio of 20%, 1% and 79% respectively, and stir them to make them fully mixed Dissolve, then add a small amount of initiator AIBN, and pass nitrogen protection into the polymerization kettle. The temperature was raised to 55° C. for 4 hours and the reaction conversion rate of the polymer was measured to be 58%.

[0045] Coagulate the polymer with normal temperature water whose volume is 5 times the volume of the reaction solution, wash 4 times with water at a temperature of 70°C and 3 times the mass of the solid matter, and vacuum dry at 65°C to constant weight. The viscosity-average molecular weight of the prepared polyacrylonitrile measured is 9.6×10 4 , the molecular weight distribution is 1.6.

[0046] Then use dimethyl sulfoxide as a solvent, the dissolution temperature is 65°C, the concentratio...

Embodiment 3

[0048] At room temperature, stir the acrylonitrile monomer, itaconic acid monomer and ionic liquid 1-butyl-3-methylimidazolium hexafluorophosphate according to the mass fraction ratio of 20.5%, 0.5% and 79% respectively, and stir them to make them fully mixed Dissolve, then add a small amount of initiator AIBN, and pass nitrogen protection into the polymerization kettle. The temperature was raised to 58° C. for 4 hours, and the reaction conversion rate of the polymer was measured to be 69%.

[0049] Coagulate the polymer with normal temperature water whose volume is 5 times the volume of the reaction solution, wash 4 times with water at a temperature of 70°C and 3 times the mass of the solid matter, and vacuum dry at 65°C to constant weight. The viscosity-average molecular weight of the prepared polyacrylonitrile measured is 12.5×10 5 , the molecular weight distribution is 1.5.

[0050] Then use dimethyl sulfoxide as a solvent, the dissolution temperature is 65°C, the concen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com