A kind of preparation method of biodegradable polylactic acid-polyethylene glycol block copolymer

A technology of block copolymer and polyethylene glycol, which is applied in the field of preparation of biodegradable copolymers, can solve the problems of difficult control of side reactions and wide molecular weight distribution, and achieve less side reactions, good controllability, and low reaction temperature Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

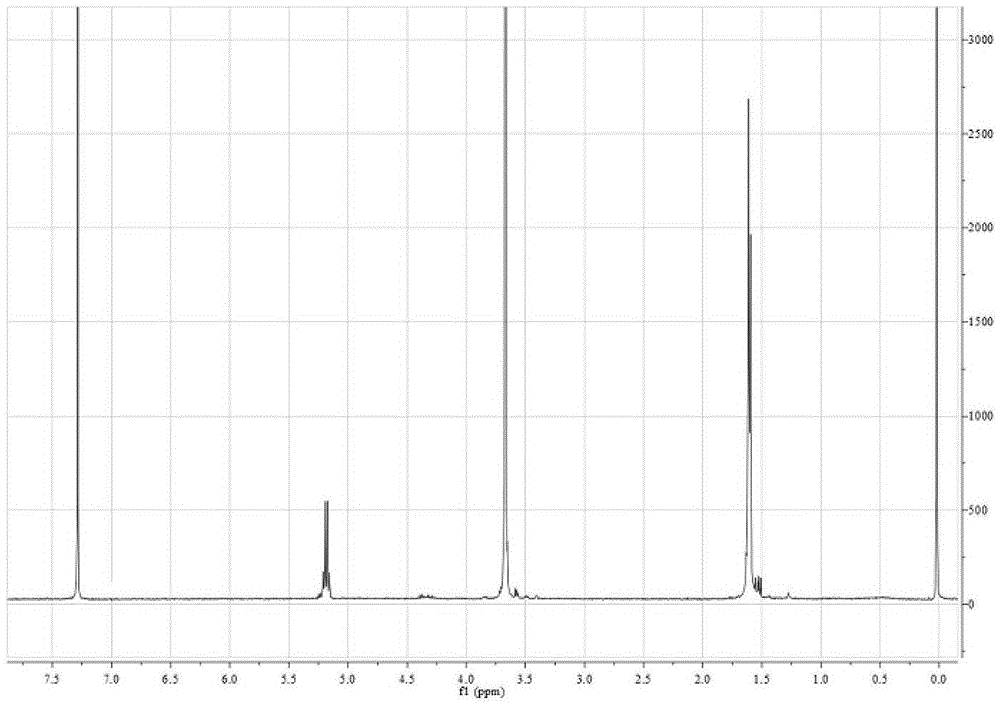

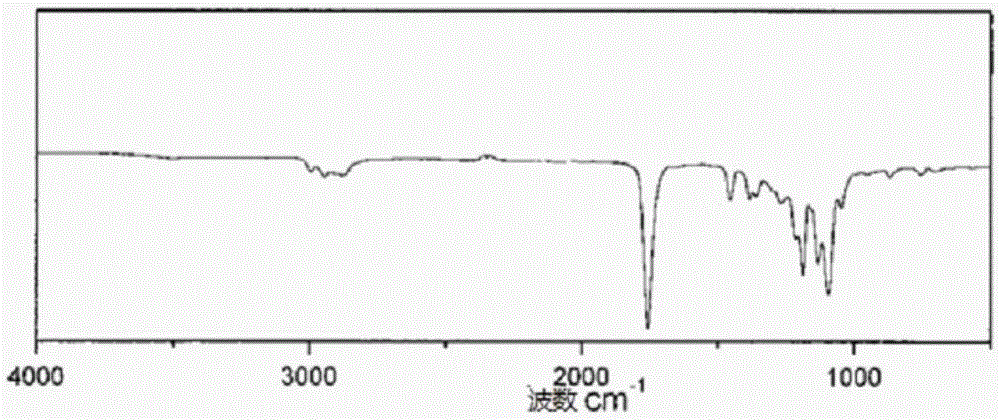

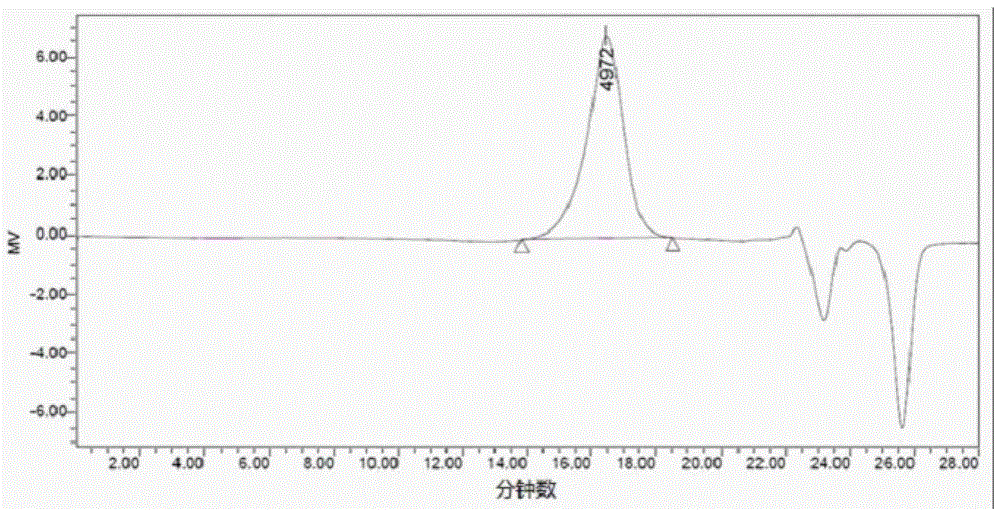

Image

Examples

Embodiment 1

[0032] With 100 ml of tetrahydrofuran as a solvent, dissolve 0.1 g of polyethylene glycol with a molecular weight of 2000, add metal potassium and naphthalene at a molar ratio of polyethylene glycol terminal hydroxyl: potassium: naphthalene = 1:1:1, and add 0.4 g under nitrogen protection. After reacting at 25°C for 48 hours, add 10 ml of acetic acid, concentrate and precipitate in a large amount of ether to obtain a polylactic acid-polyethylene glycol triblock copolymer.

Embodiment 2

[0033] Example 2: With 50 milliliters of dioxane as a solvent, dissolve 5 grams of polyethylene glycol monomethyl ether with a molecular weight of 5000, and add it according to the molar ratio of polyethylene glycol terminal hydroxyl: sodium: naphthalene = 1:10:1 Metal sodium and naphthalene, under the protection of nitrogen, add 10 grams of lactide in 50 ml of dioxane solution, react at 60 ° C for 24 hours, add 5 ml of hydrochloric acid, concentrate and precipitate in a large amount of ether to obtain polylactic acid-poly Ethylene glycol diblock copolymer.

Embodiment 3

[0034] Example 3: Using 50 ml of methylpyrrolidone as a solvent, dissolve 50 grams of polyethylene glycol monomethyl ether with a molecular weight of 1000, and add the metal according to the molar ratio of polyethylene glycol terminal hydroxyl: sodium: naphthalene = 1:5:1 Sodium and naphthalene, add 50 grams of lactide in 50 milliliters of methyl pyrrolidone solution under nitrogen protection, react at 50 ° C for 18 hours, add 5 milliliters of formic acid, concentrate and precipitate in a large amount of ether to obtain polylactic acid-polyethylene glycol Alcohol Diblock Copolymer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| polydispersity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com