Continuous long glass fiber reinforced PBT composite material and preparation method thereof

A composite material and long glass fiber technology, which is applied in the field of continuous long glass fiber modified and reinforced PBT composite materials and its preparation, can solve the problems of demanding performance requirements of composite materials, application limitations of short fiber reinforced PBT composite materials, etc., and achieve enhanced Impregnation effect, improvement of surface finish, good effect of temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

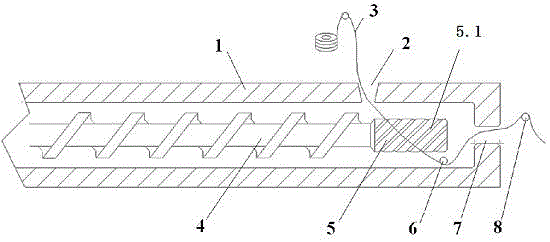

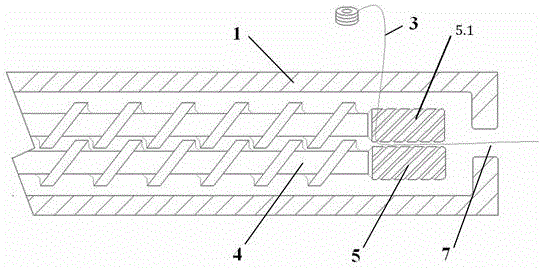

[0023] The preparation method of the long glass fiber reinforced PBT composite material in this embodiment includes the following steps: (1) adding PBT resin, flow modifier, toughening agent, nucleating agent, antioxidant, lubricant and POE component Make it fully mixed in the mixer;

[0024] (2) Add the above mixture into the twin-screw extruder through the feeding port, set the extrusion temperature at 200-235°C, set the temperature of the long glass fiber impregnating head at 230-250°C, and the material in the extruder The residence time is 3-8min, and the speed of the host is controlled at 250-350r·min -1 , the PBT molten primer is injected into the impregnation chamber of the long glass fiber impregnation head by co-rotating twin-screws;

[0025] (3) The long glass fiber is preheated and dried through a 70-80°C hot air pipe, and the long glass fiber is coated on the surface of the glass fiber in an aqueous solution with aminosilane or 3-aminopropyltrihydroxysilane during...

Embodiment 1

[0031] According to mass fraction, 73 parts of PBT (intrinsic viscosity is 1.0dL / g), 3 parts of CBT100, 2 parts of PTW, 1 part of sodium benzoate, 0.1 part of antioxidant 1076, 0.2 part of antioxidant 168, 0.4 part of silicone Mix the powder evenly in a mixer; put it into a twin-screw extruder, inject it into a long glass fiber impregnation head after melting, set the temperature of the extruder at 220-230°C, and set the temperature of the impregnation head at 245°C; put 20 parts of long glass fiber The glass fiber (E-type non-alkali roving) is preheated and dried by 80°C hot air pipe, and the long glass fiber is coated with 3-aminopropyltrihydroxysilane as an aqueous solution on the surface of the glass fiber during the spinning process to make the long glass fiber There are hydroxyl and amino groups on the surface of the glass fiber. The long glass fiber passes through the acetone solution of MDI at a linear speed of 1m / min. The MDI and acetone are mixed at a volume ratio of ...

Embodiment 2

[0033] According to the mass fraction, 59 parts of PBT (intrinsic viscosity is 1.0dL / g), 4 parts of CBT100, 4 parts of AX8900, 2.3 parts of POE, 2 parts of sodium benzoate, 0.2 parts of antioxidant 1010, 0.2 parts of antioxidant 168, Mix 0.4 parts of PETS evenly in a mixer; put it into a twin-screw extruder, inject it into a long glass fiber impregnation head after melting, set the temperature of the extruder at 220-230°C, and set the temperature of the impregnation head at 245°C; One piece of long glass fiber (E-type non-alkali roving) is preheated and dried by 80°C hot air pipe. During the spinning process, the long glass fiber is coated with 3-aminopropyltrihydroxysilane in aqueous solution on the surface of the glass fiber. Make the surface of the long glass fiber have hydroxyl and amino groups, the long glass fiber passes through the acetone solution of TDI at a linear speed of 0.8m / min, mix TDI and acetone at a volume ratio of 1:1, and then pass the long glass fiber throu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Intrinsic viscosity | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com