Method for synthesizing poly(sodium-styrenesulfonate) with terpyridyl ruthenium initiator

A technology of sodium polystyrene sulfonate and ruthenium terpyridine, which is applied in the field of synthesizing sodium polystyrene sulfonate, controllable PSS, and uniform molecular weight, which can solve the development limitation of photo-induced RAFT polymerization and the narrow wavelength range of photo-polymerization , low initiator initiation efficiency and other issues, to achieve the effect of good product quality, strong stability and high preparation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] 1. Using ruthenium terpyridine as a photoinitiator to initiate RAFT polymerization to prepare polymer PSS:

[0029] (1) Put 40mg RAFT reagent (4-cyano-4-ethyltrithiovaleric acid, CETP), 4g sodium p-styrenesulfonate and 5mg ruthenium terpyridyl in a 50mL volumetric flask with 8mL water and 9mL di Oxycycline was dissolved to obtain a reagent for subsequent use;

[0030] (2) feed nitrogen into the volumetric flask equipped with reagent in step (1) to remove oxygen for 70 minutes;

[0031] (3) irradiating the volumetric flask after deoxygenation in step (2) for 24h under the blue light of 200W;

[0032] (4) dialyze the product obtained in step (3) in ultrapure water for 4 days, then put it into a vacuum box and dry it to obtain the polymer PSS;

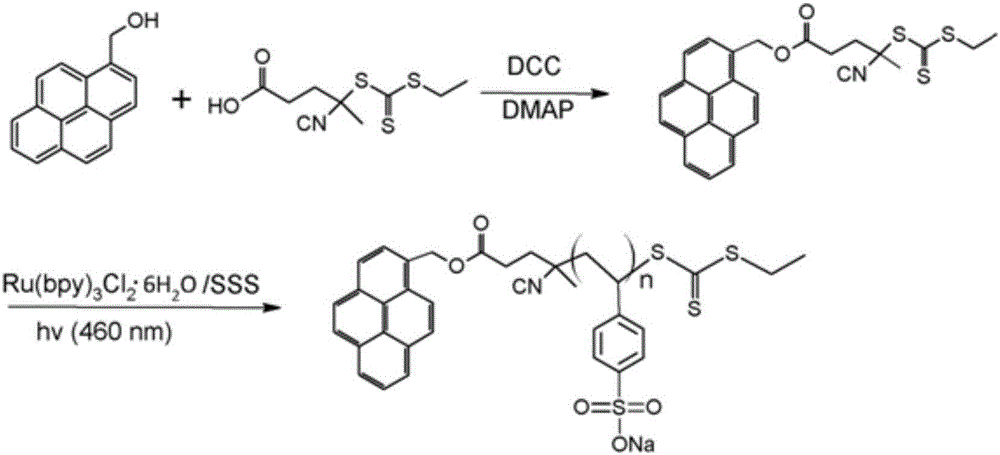

[0033] 2. Pyrene functionalization of RAFT reagent (CETP):

[0034] (1) Dissolve 0.5g pyrenemethanol, 0.73g CETP, 0.6383g dicyclohexylcarbodiimide (DCC) and 0.0378g 4-dimethylaminopyridine (DMAP) in 10mL tetrahydrofuran (THF) re...

Embodiment 2

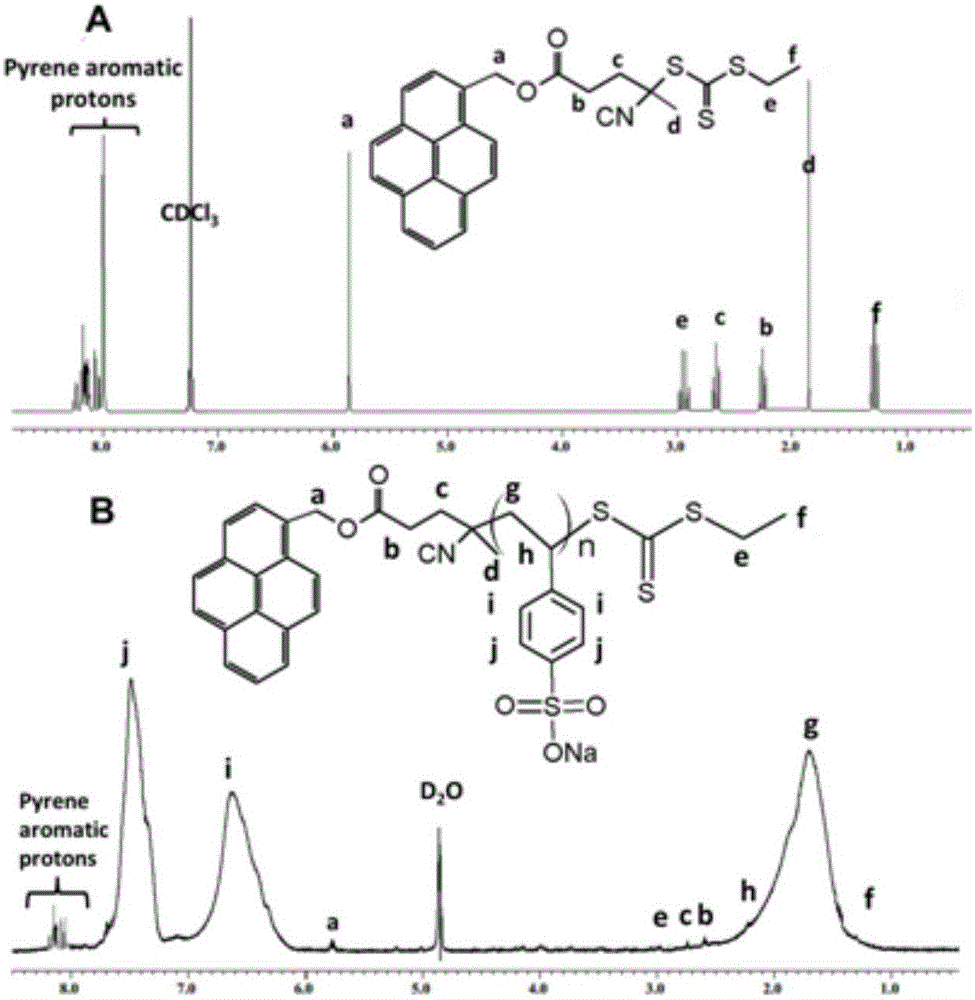

[0043] In this example, the synthetic PCETP and PSS were characterized by NMR. figure 2 A is the NMR characterization of PECTP, figure 2 B is the NMR characterization of PSS. Through the analysis of each peak position on the NMR spectrum, it is proved that PCETP and PSS were successfully synthesized in this embodiment.

Embodiment 3

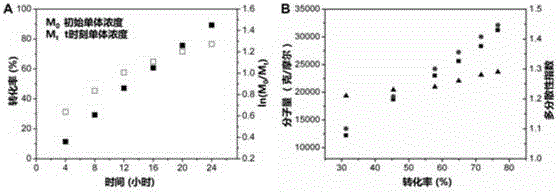

[0045] The present embodiment has characterized the molecular weight, dispersity and conversion rate of PSS, as image 3 Shown in A, the reaction time increases, and the conversion rate of polymer PSS is higher and higher, reaches 79% in 24 hours; As image 3 As shown in B, the difference between the molecular weight of the polymer measured by gel permeation chromatography (GPC) and the theoretical molecular weight is within 2%, and the molecular weight distribution of PSS is very narrow, less than 1.28.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com