Praseodymium ion-doped potassium strontium borate fluorescent powder and high-temperature solid-phase preparation method

A technology of high-temperature solid phase and fluorescent powder, which is applied in the direction of chemical instruments and methods, luminescent materials, etc., and can solve the problems of electronegativity and the influence of radius luminescence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

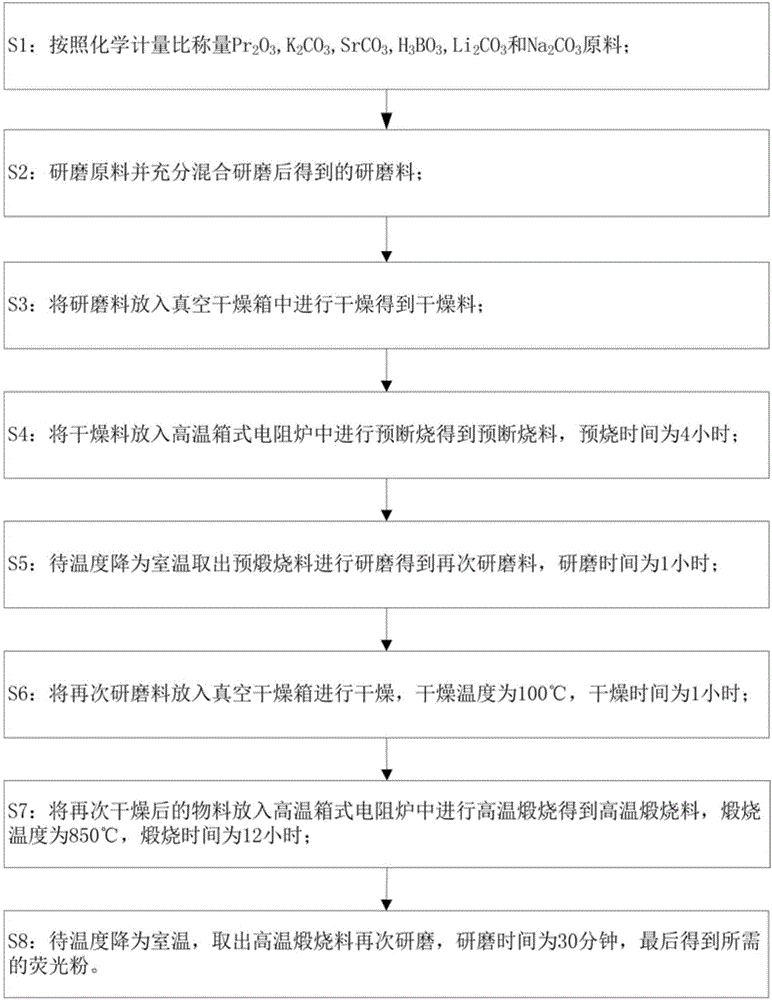

[0041] Such as figure 1 As shown, the high-temperature solid-phase preparation method of potassium strontium borate phosphor doped with praseodymium ions provided in this embodiment includes the following steps:

[0042] S1: Weighing Pr according to the stoichiometric ratio 2 o 3 , K 2 CO 3 , SrCO 3 , HBO 3 , Li 2 CO 3 and Na 2 CO 3 raw material;

[0043] S2: Grinding raw materials and fully mixing and grinding to obtain abrasives;

[0044] S3: putting the grinding material into a vacuum drying oven for drying to obtain a dry material;

[0045] S4: put the dried material into a high-temperature box-type resistance furnace for pre-calcination to obtain a pre-calcined material, the pre-calcined temperature is 400-600°C, and the pre-calcined time is 3-6 hours;

[0046] S5: After the temperature drops to room temperature, take out the pre-calcined material and grind it to obtain the re-ground material, and the grinding time is 0.8-1.2 hours;

[0047] S6: put the regri...

Embodiment 2

[0061] The specific steps of the high-temperature solid-phase preparation method of potassium strontium borate phosphor doped with praseodymium ions provided in this embodiment are as follows:

[0062] Weigh Pr according to the stoichiometric ratio 2 o 3 , K 2 CO 3 , SrCO 3 , HBO 3 , Li 2 CO 3 , Na 2 CO 3 raw material;

[0063] Grinding raw materials and thoroughly mixing the ground raw materials;

[0064] Dry the ground raw material in a vacuum drying oven;

[0065] Put it into a high-temperature box-type resistance furnace and pre-calcine at 500 ° C for 5 hours.

[0066] When the temperature drops to room temperature, take it out and grind it in an agate mortar for 1.1 hours.

[0067] Then move it into a corundum crucible, put it in a vacuum drying oven and dry it at 100°C for 1.1 hours,

[0068] Then put it into a high-temperature box-type resistance furnace, and perform high-temperature calcination at 850° C. for 16 hours.

[0069] When the temperature drops ...

Embodiment 3

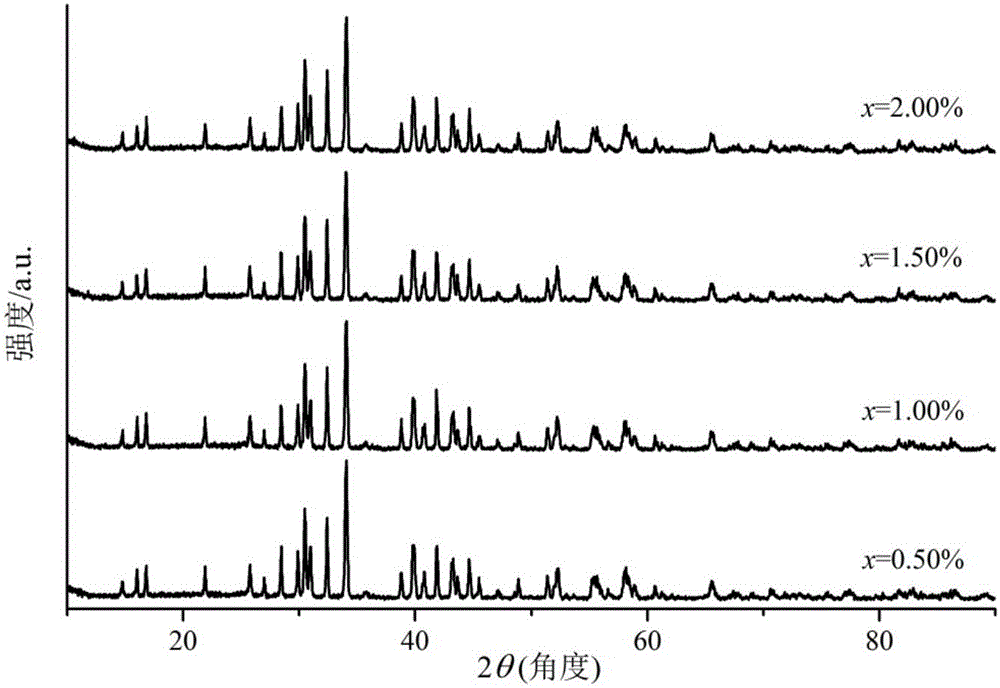

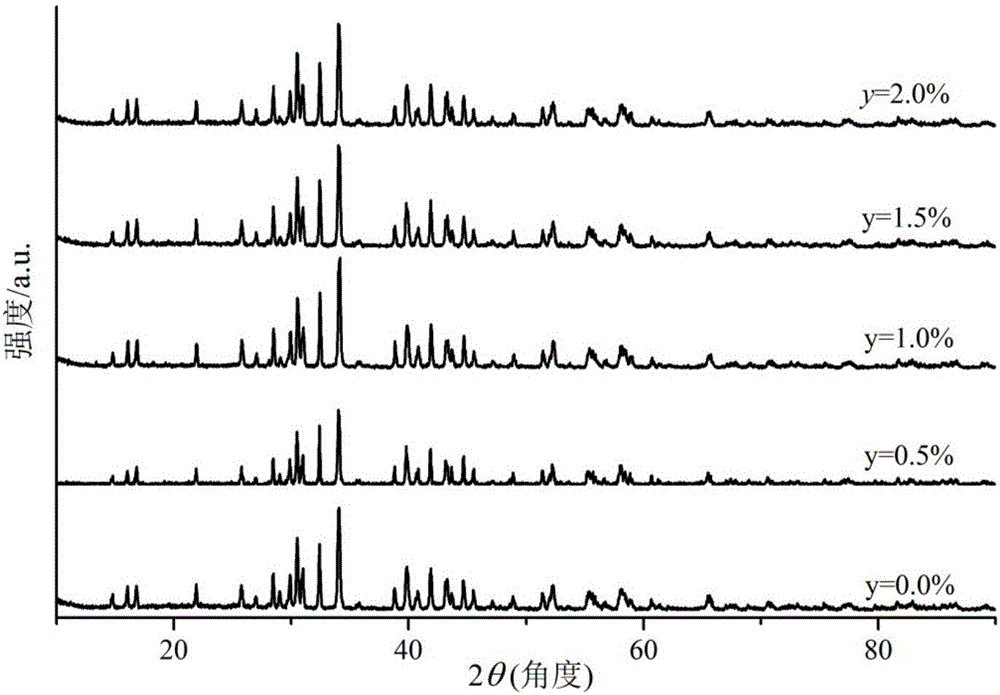

[0080] The phosphor preparation method provided in this embodiment is to prepare potassium strontium borate phosphor doped with praseodymium ions by using a high-temperature solid-phase method. Replace potassium ions and strontium ions with praseodymium ions, replace strontium ions and praseodymium ions by doping charge compensators, the XRD pattern, SEM pattern, and spectrum of the sample, such as Figure 2-10 As shown; among them, SEM HV indicates the working voltage in ultra-high vacuum; SEMMAG indicates the magnification; WD indicates the working distance; Det:SE indicates the detector type; MIRA3 TESCAN indicates the model of thermal field emission scanning electron microscope; performance in nanospace indicates the operation mode .

[0081] (1) The XRD diffraction pattern of the experimental sample is compared with the pattern of the relevant literature, and the diffraction peaks are consistent, which shows that KSr was synthesized 4 (BO 3 ) 3 crystal, and the charge ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| emission peak | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com