Preparation method of three-phase composite photocatalytic material

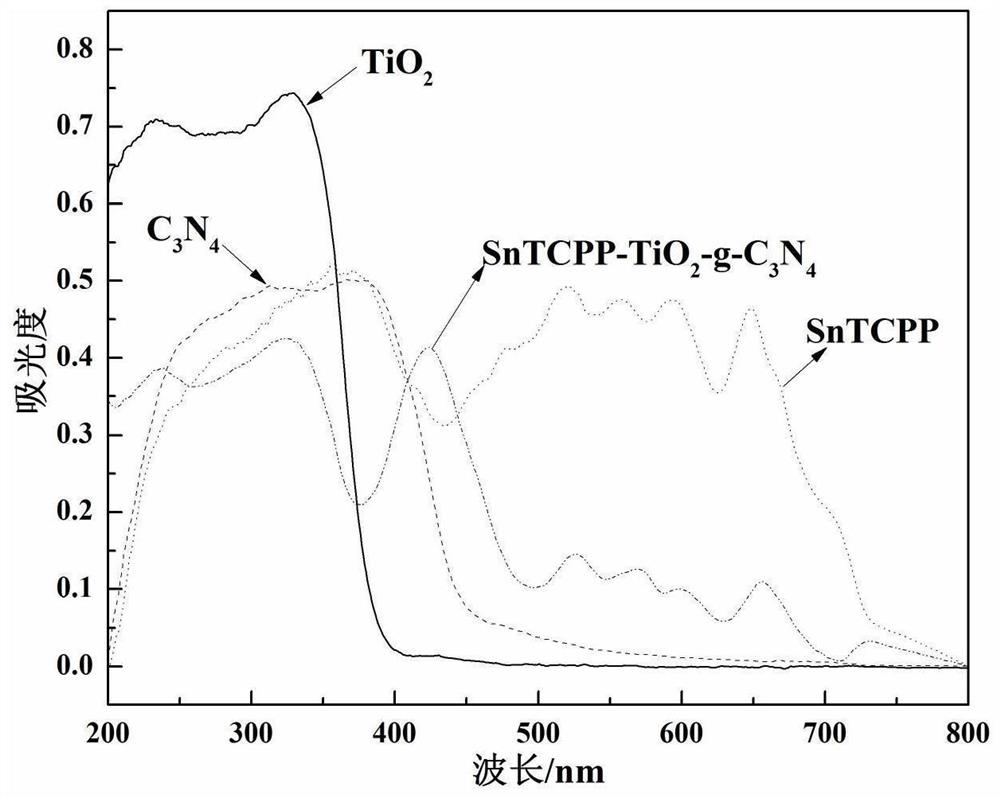

A composite photocatalysis and composite material technology, which is applied in the field of preparation of three-phase composite photocatalytic materials, can solve problems such as modification effects that have not been tried yet, and achieve high visible light capture capacity, mild reaction conditions, and good transmission effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

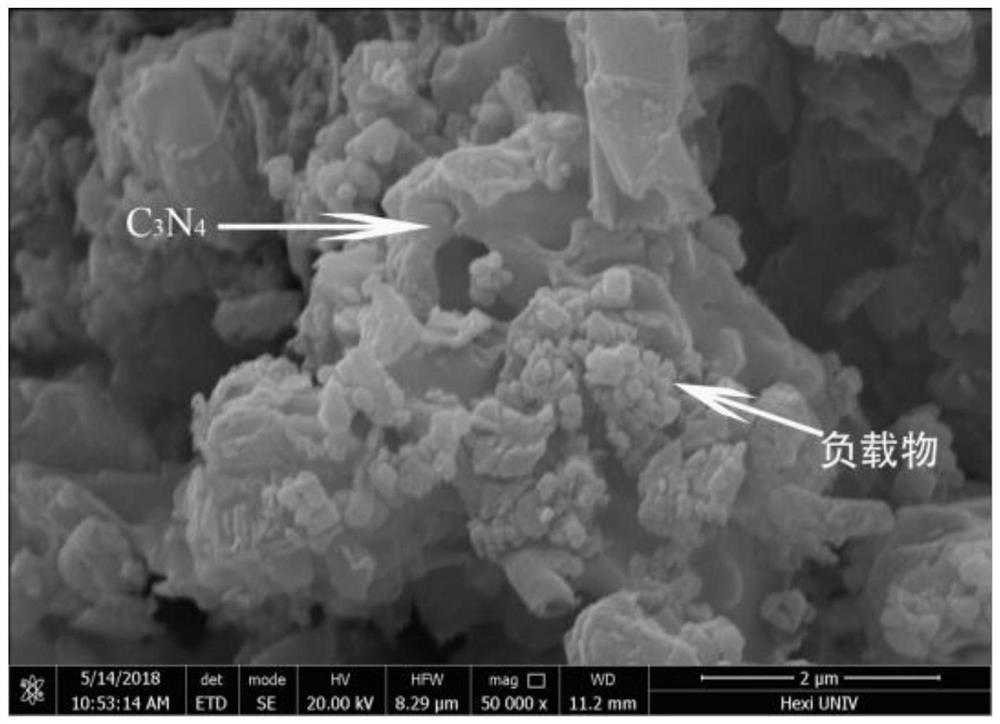

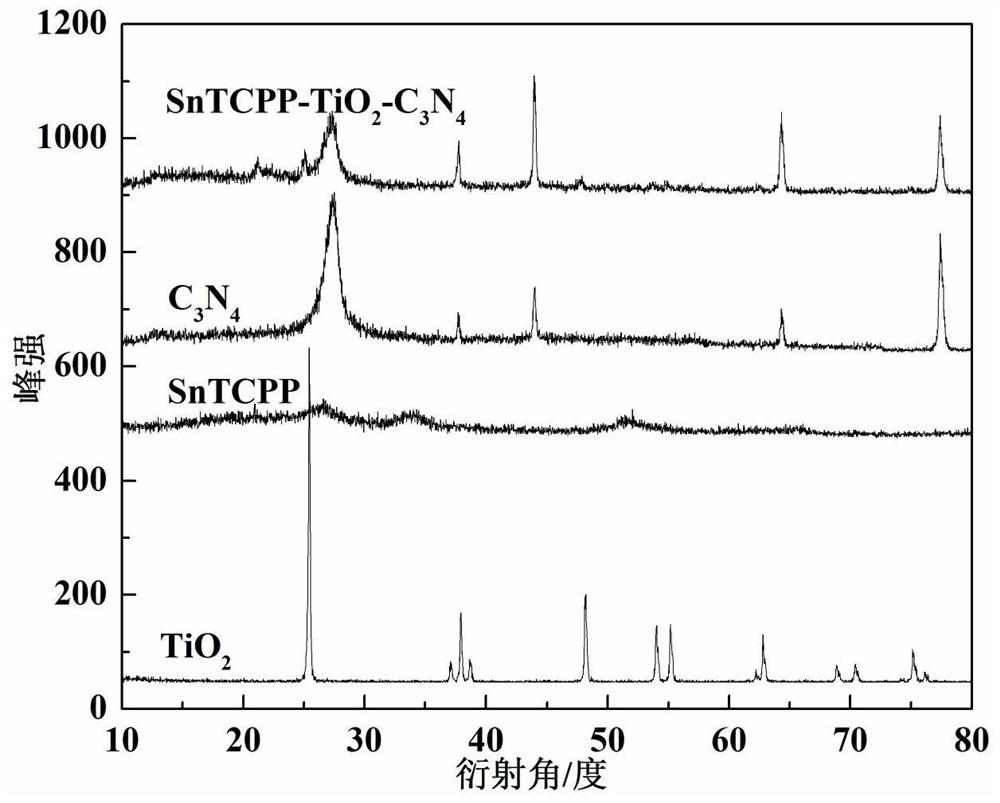

Method used

Image

Examples

preparation example Construction

[0039] A preparation method of a three-phase composite photocatalytic material, specifically comprising the following steps:

[0040] Step 1: Put C 3 h 3 N 6 and CH 4 N 2 The mixture of S is applied high temperature calcination method to prepare graphite phase carbon nitride g-C 3 N 4 ,Specifically:

[0041] Step 1.1, weigh an appropriate amount of melamine C 3 h 3 N 6 with thiourea CH 4 N 2 S mixed well in a mortar, C 3 h 3 N 6 with CH 4 N 2 The weight ratio of S is 5:1~8:1;

[0042] Step 1.2, put the mixture obtained in step 1.1 into a semi-closed alumina crucible, cover it and place it in a muffle furnace at a heating rate of 2°C / min to 550°C-600°C for 4 hours, then cool down to room temperature to obtain Yellow powdery solid, dried and ground to give g-C 3 N 4 .

[0043] Step 2, take carboxybenzaldehyde, pyrrole and anhydrous tin chloride as raw materials, prepare tetracarboxyphenyl tin porphyrin SnTCPP, specifically:

[0044] Step 2.1, weigh 2.16g of ...

Embodiment 1

[0056] Step 1: Put C 3 h 3 N 6 and CH 4 N 2 The mixture of S uses high temperature calcination method to prepare g-C 3 N 4 ,Specifically:

[0057] Step 1.1: Weigh C with a weight ratio of 5:1 3 h 3 N 6 with CH 4 N 2 Mix well in a mortar;

[0058] Step 1.2: Place the mixture obtained in Step 1.1 in a semi-closed alumina crucible, cover it and place it in a muffle furnace at a heating rate of 2°C / min to 550°C for 4 hours, then cool down to room temperature to obtain a light yellow powder solid, dried and ground to give g-C 3 N 4 .

[0059] Step 2: take carboxybenzaldehyde, pyrrole and anhydrous tin chloride as raw materials, prepare tetracarboxyphenyl tin porphyrin SnTCPP, specifically:

[0060] Step 2.1: Weigh 2.16g of 4-formylbenzoic acid into a three-necked flask, pour 150mL of propionic acid, heat the oil bath to 135°C, slowly add the mixture of 1mL of pyrrole and 20mL of propionic acid dropwise, and control it within 60min After the dropwise addition, reflux...

Embodiment 2

[0077] Step 1: Prepare g-C 3 N 4 ,Specifically:

[0078] Step 1.1: Weigh C with a weight ratio of 6:1 3 h 3 N 6 with CH 4 N 2 Mix well in a mortar;

[0079] Step 1.2: Place the mixture obtained in step 1.1 in a semi-closed alumina crucible, cover it and place it in a muffle furnace at a heating rate of 2°C / min to 600°C for 4 hours, then cool down to room temperature to obtain a light yellow powder solid, dried and ground to give g-C 3 N 4 .

[0080] Step 2: prepare tetracarboxyphenyl tin porphyrin SnTCPP, specifically:

[0081] Step 2.1: Weigh 2.16g of 4-formylbenzoic acid into a three-necked flask, pour 150mL of propionic acid, heat the oil bath to 135°C, slowly add the mixture of 1mL of pyrrole and 20mL of propionic acid dropwise, and control it within 60min After the dropwise addition, reflux at 140°C for 2 hours after the dropwise addition;

[0082] Step 2.2: Cool the reaction product of step 2.1 to room temperature, add 50mL of ethanol and put it in the refrig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com