A method for one-step hydrothermal preparation of molybdenum disulfide quantum dots using sulfur as a sulfur source

A technology of molybdenum disulfide and quantum dots, which is applied in the field of nanomaterials, can solve the problems of difficult sulfur and limited application, and achieves the effects of low preparation cost, reduced synthesis difficulty and danger, and stable performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

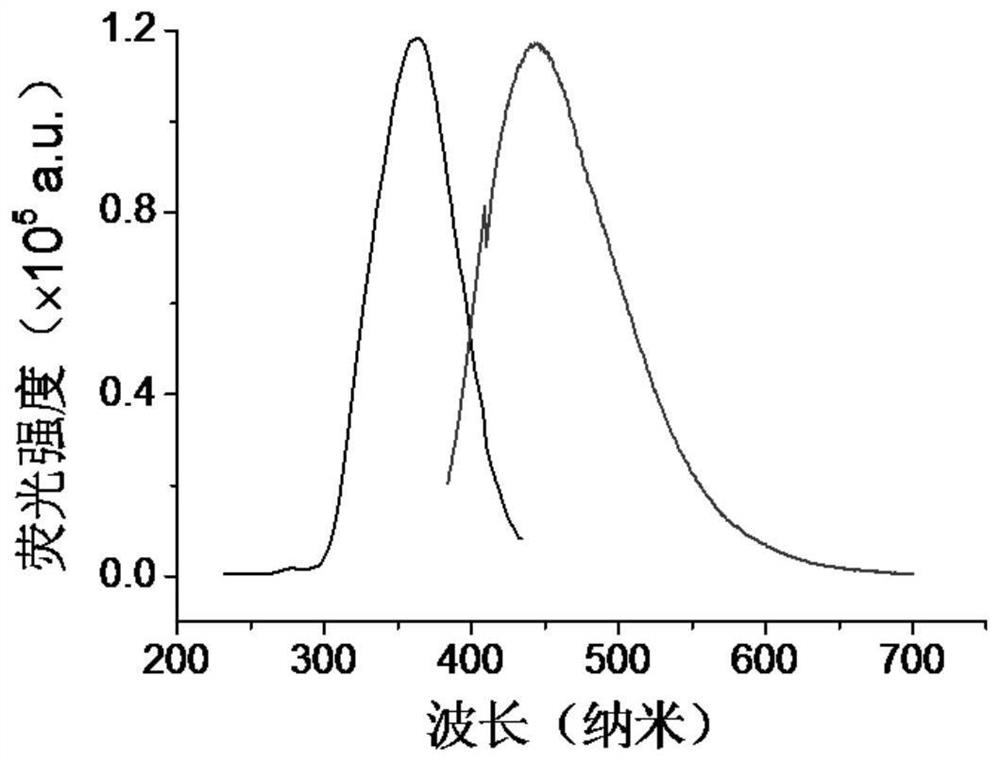

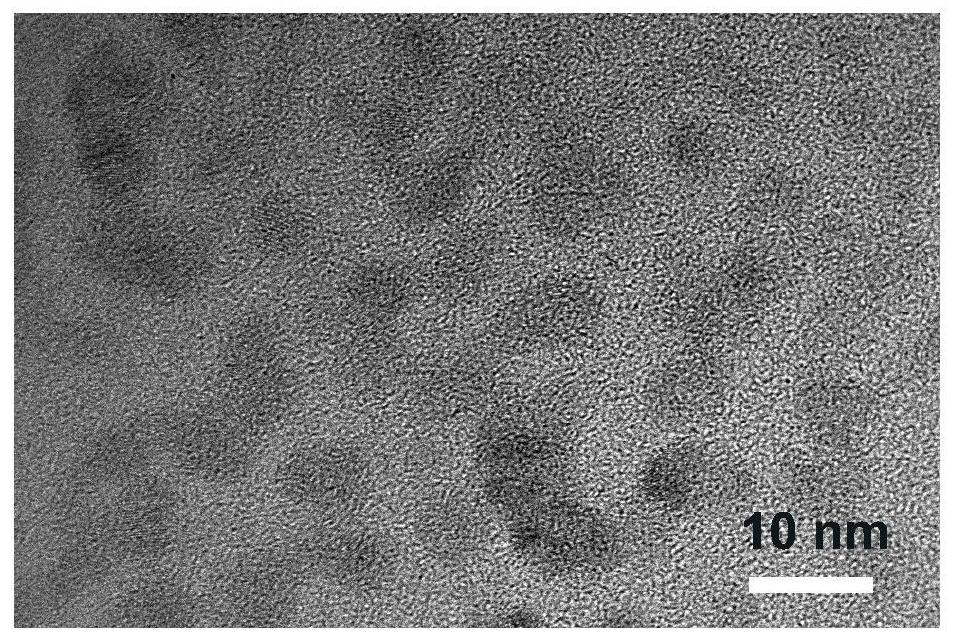

[0022] Dissolve 96 mg of sulfur in 10 mL of 50% hydrazine hydrate and stir at room temperature in the dark until the sulfur powder is completely dissolved to obtain 0.3 M S-N 2 h 4 ·H 2 O (concentration is calculated based on the content of sulfur element). Then 22 mM sodium molybdate dihydrate (Na 2 MoO 4 ·H 2 O) Place in ultrapure water, add 44 mM S-N 2 h 4 ·H 2 O, followed by ultrasonication for 10 min, placed in a reactor at 200 °C for 8 h. like figure 1 and figure 2 As shown, the optimal excitation and emission wavelengths of the synthesized molybdenum disulfide quantum dots are 362 nm and 445 nm, respectively, and the average particle size of the molybdenum disulfide quantum dots synthesized by this method is below 5 nm.

Embodiment 2

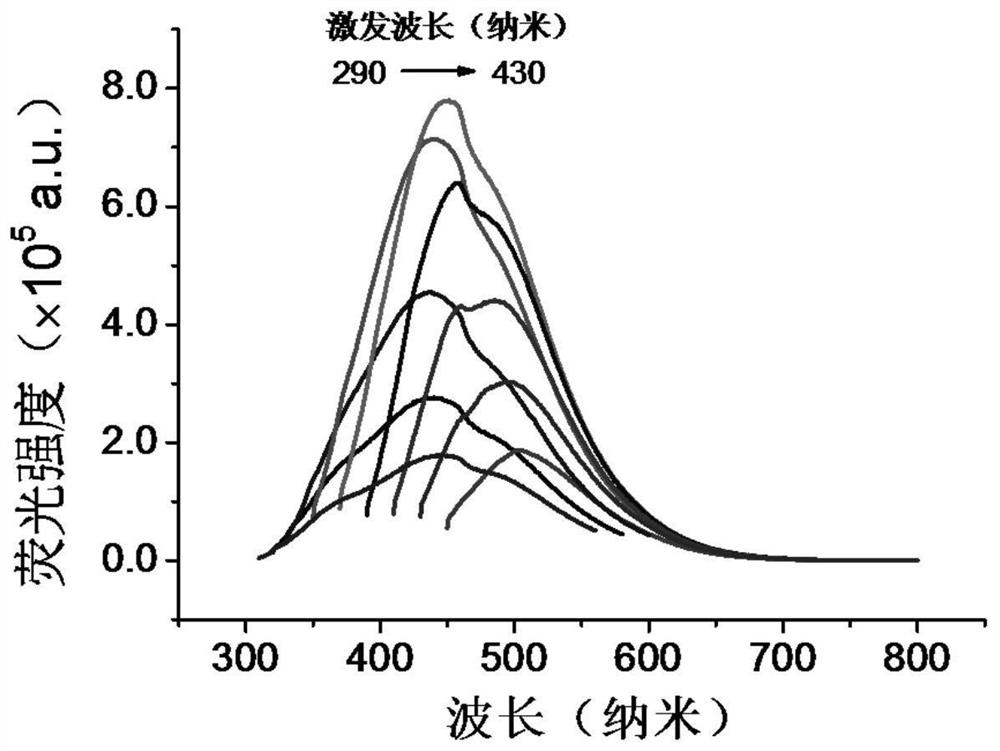

[0024] Dissolve 96 mg of sulfur in 10 mL of 50% hydrazine hydrate, and stir at room temperature in the dark until the sulfur powder is completely dissolved to obtain 0.3 M S-N 2 h 4 ·H 2 O (concentration is calculated based on the content of sulfur element). Then 30 mM ammonium molybdate ((NH 4 ) 2 MoO 4 ) in ultrapure water, add 60 mM S-N 2 h 4 ·H 2 O, followed by ultrasonication for 5 min, placed in a reaction kettle at 200 °C for 4 h. like image 3 and Figure 4 As shown, the molybdenum disulfide quantum dots synthesized by this method have the property of tunable fluorescence emission, and can fluoresce under the excitation of 290 nm to 430 nm light, and the maximum excitation and emission wavelengths of the fluorescence are 350 nm and 454 nm, respectively.

Embodiment 3

[0026] Dissolve 96 mg of sulfur in 5.88 mL of 85% hydrazine hydrate, and stir at room temperature in the dark until the sulfur powder is completely dissolved to obtain 0.5 M S-N 2 h 4 ·H 2 O (concentration is calculated based on the content of sulfur element). Then 30 mM ammonium dimolybdate ((NH 4 ) 2 Mo 2 o 7 ) in ultrapure water, add 75 mM S-N 2 h 4 ·H 2 O, followed by ultrasonication for 10 min, placed in a reactor at 220 °C for 4 h. like Figure 5 and Figure 6 As shown, the fluorescence maximum excitation and emission wavelengths of molybdenum disulfide quantum dots synthesized by this method are 360 nm and 460 nm, respectively, and it has a significant ultraviolet absorption peak at 228 nm, and an inconspicuous ultraviolet absorption peak at 292 nm. UV absorption peak.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com