Method for preparing butadiene-isoprene copolymer

A technology of isoprene and butadiene, applied in the field of preparation of butadiene-isoprene copolymers, can solve the problems of low molecular weight, wide molecular weight distribution, and no preparation mentioned

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

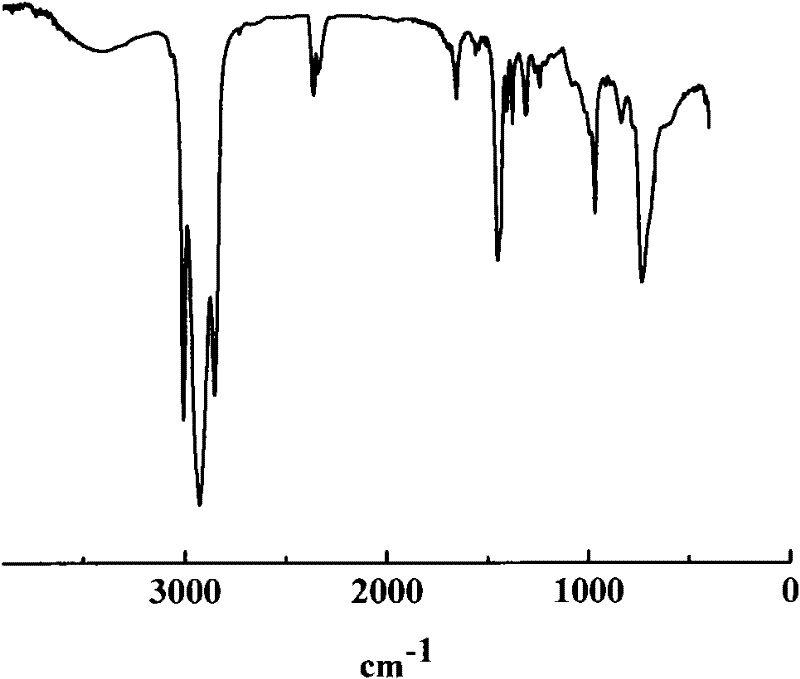

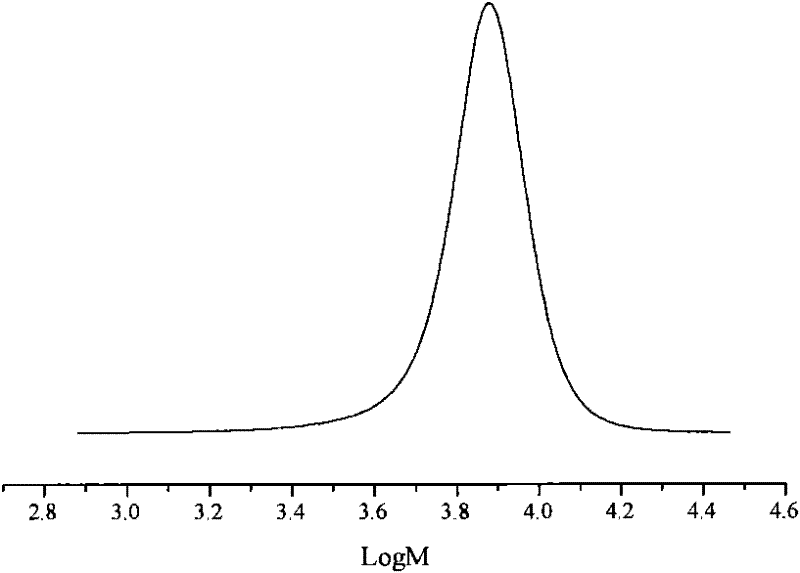

Image

Examples

preparation example Construction

[0031] A preparation method of butadiene-isoprene copolymer, comprising:

[0032] a) reacting the reaction monomer and the solvent under the action of a catalyst to obtain a solution A;

[0033] b) adding ethanol solution to the solution A to coagulate butadiene and isoprene copolymer;

[0034] The reactive monomers are butadiene and isoprene,

[0035] The molar ratio of the reaction monomer to the catalyst is 100~4000:1,

[0036] The preparation method of described catalyst is:

[0037] Mixing and reacting the rare earth compound, butadiene, isoprene and alkylaluminum to obtain solution B;

[0038] Chloride was added to solution B for reaction to obtain a catalyst.

[0039] In addition, the present invention also includes:

[0040] Add 2,6-di-tert-butyl-p-cresol with a mass concentration of 0.005g / ml to 0.02g / ml into the solution A, and the 2,6-di-tert-butyl-p-cresol is an anti-aging agent , the trade name is anti-aging agent 264.

[0041] The present invention also in...

Embodiment 1

[0058] Under the protection of nitrogen, add neodymium neodecanoate (Nd), butadiene (BD) or isoprene (IP) and diisobutylaluminum hydride (Al) successively to the dry catalyst reaction flask, at 50 After reacting at °C for 5 minutes, dimethyldichlorosilane (Cl) was added and reacted at 25°C for 30 minutes to obtain a catalyst for the polymerization of butadiene and isoprene. In this catalyst, the molar ratio of [Nd] / [BD / IP] / [Al] / [Cl] is 1 / 10 / 30 / 2 / 0.

[0059] Under the protection of nitrogen, add 20 mL of the hexane solution of the reaction monomers butadiene and isoprene to a dry 50 mL reaction flask, the molar ratio of butadiene and isoprene is 4:1, and then add the above-mentioned For a good catalyst, the molar ratio of reaction monomer to catalyst is 400:1;

[0060] The polymerization reaction is carried out at 50°C, and after 4 hours of the polymerization reaction, the ethanol solution of anti-aging agent 264 with a mass concentration of 0.01 g / ml is terminated, and a low ...

Embodiment 2

[0062] Under the protection of nitrogen, add neodymium neodecanoate (Nd), butadiene (BD) or isoprene (IP) and diisobutylaluminum hydride (Al) successively to the dry catalyst reaction flask, at 50 After reacting at ℃ for 5 minutes, chlorobutylaluminum (Cl) was added and reacted at 25℃ for 30 minutes to obtain a catalyst for the polymerization of butadiene and isoprene. In this catalyst, the molar ratio of [Nd] / [BD / IP] / [Al] / [Cl] is 1 / 10 / 20 / 2.0.

[0063] Under the protection of nitrogen, add 20 mL of the hexane solution of the reaction monomers butadiene and isoprene to a dry 50 mL reaction flask, the molar ratio of butadiene and isoprene is 4:1, and then add the above-mentioned For a good catalyst, the molar ratio of reaction monomer to catalyst is 400:1;

[0064] The polymerization reaction is carried out at 50°C, and after 4 hours of the polymerization reaction, the ethanol solution of anti-aging agent 264 with a mass concentration of 0.01 g / ml is terminated, and a low molec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com