Producing method for spinning heterogeneous colored terylene preoriented continuous yarn by recycled polyester bottle sheet materials

A technology of polyester bottle flakes and colored polyester, which is applied in filament forming treatment, filament/thread forming, textile and papermaking, etc., to achieve the effect of expanding the scope of application, expanding the scope of application and broad development prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

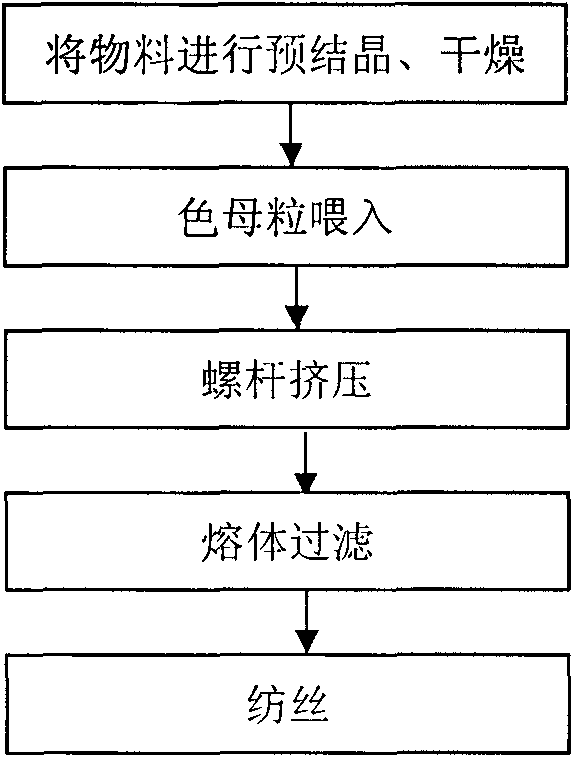

Method used

Image

Examples

Embodiment 1

[0023] This embodiment is the production process of producing 267dtex / 36f special-shaped colored polyester pre-oriented yarn, and its production process is as follows: the recycled polyester bottle flakes (moisture content at 40ppm) and polyester color masterbatch that the intrinsic viscosity is 0.70 and polyester color masterbatch are adopted. The masterbatch accounts for 3% of the total amount of the mixture, and it is fed into an extruder with a diameter of Φ58mm and a screw length-to-diameter ratio (L / D) of 48, and recycled polyester bottle flakes and special color masterbatch Melt in the extruder, filter through a continuous filter (filtering precision is 25μm, the melt pressure before filtration is 12Mpa, the melt pressure after filtration is controlled at 10Mpa, and the melt temperature is 292°C), and then metered by a gear pump. After entering the spinning box for spinning, the melt is spun through the "non"-shaped spinneret holes on the Φ80mm36-hole spinneret, and then...

Embodiment 2

[0029] This embodiment is the production method of the 540dtex / 96f "non" shaped special-shaped colored polyester pre-oriented yarn variety, and its production process is as follows: using recycled polyester bottle flakes (with a moisture content of 50 ppm) and polyester with an intrinsic viscosity of 0.80 Color masterbatch, color masterbatch accounts for 6% of the total amount of the mixture, and it is fed into an extruder with a diameter of Φ58mm and a screw length-to-diameter ratio (L / D) of 48, recycled polyester bottle flakes and special The color masterbatch is melted in a screw extruder, and filtered through a continuous filter (filtering precision is 25 μm, the melt pressure before filtering is 12Mpa, the melt pressure after filtering is controlled at 10Mpa, and the melt temperature is 290°C), and then After being metered by the gear pump, it enters the spinning box for spinning. After the melt is spun through the "non"-shaped spinneret hole on the Φ100mm 96-hole spinnere...

Embodiment 3

[0035] This embodiment is the production method of 165dtex / 48f "Non" shaped special-shaped colored polyester pre-oriented yarn variety, and its production process is as follows: using recycled polyester bottle flakes (moisture content at 45ppm) with an intrinsic viscosity of 0.90 and polyester Color masterbatch, color masterbatch accounts for 10% of the total amount of the mixture, and it is fed into an extruder with a diameter of Φ58mm and a screw length-to-diameter ratio (L / D) of 48, recycled polyester bottle flakes and special The color masterbatch is melted in a screw extruder, filtered through a continuous filter (filtering precision is 25 μm, the melt pressure before filtration is 12Mpa, the melt pressure after filtration is controlled at 10Mpa, and the melt temperature is 291°C), and then After being metered by the gear pump, it enters the spinning box for spinning. After the melt is spun through the "non"-shaped spinneret hole on the spinneret with Φ80mm and 48 holes, i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Breaking strength | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com