Process for manufacturing fire-retardant polyester fiber

A polyester fiber and manufacturing process technology, applied in the manufacture of fire-resistant and flame-retardant filaments, single-component polyester artificial filaments, fiber treatment, etc., can solve problems such as low efficiency, many broken ends, and slight toxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

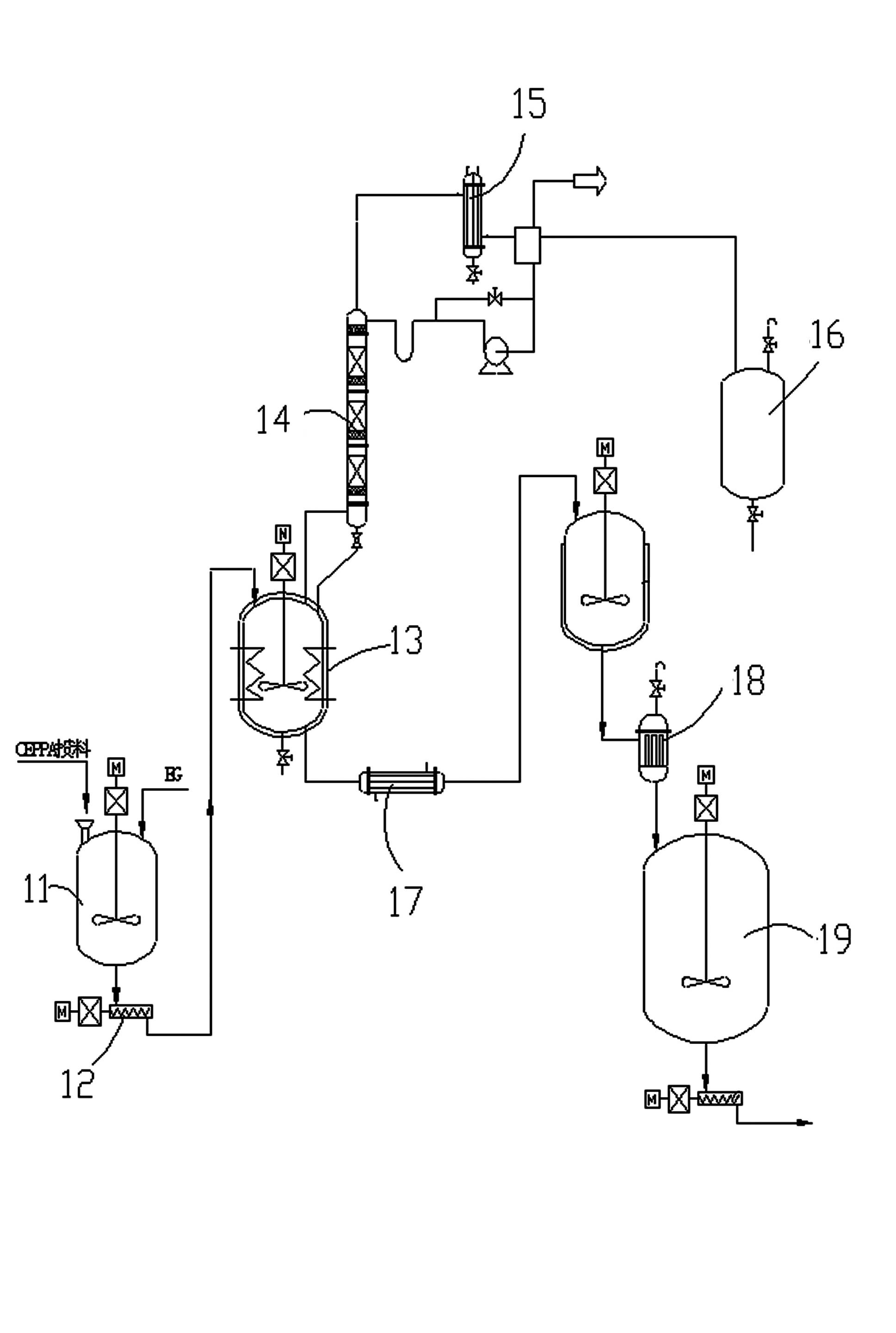

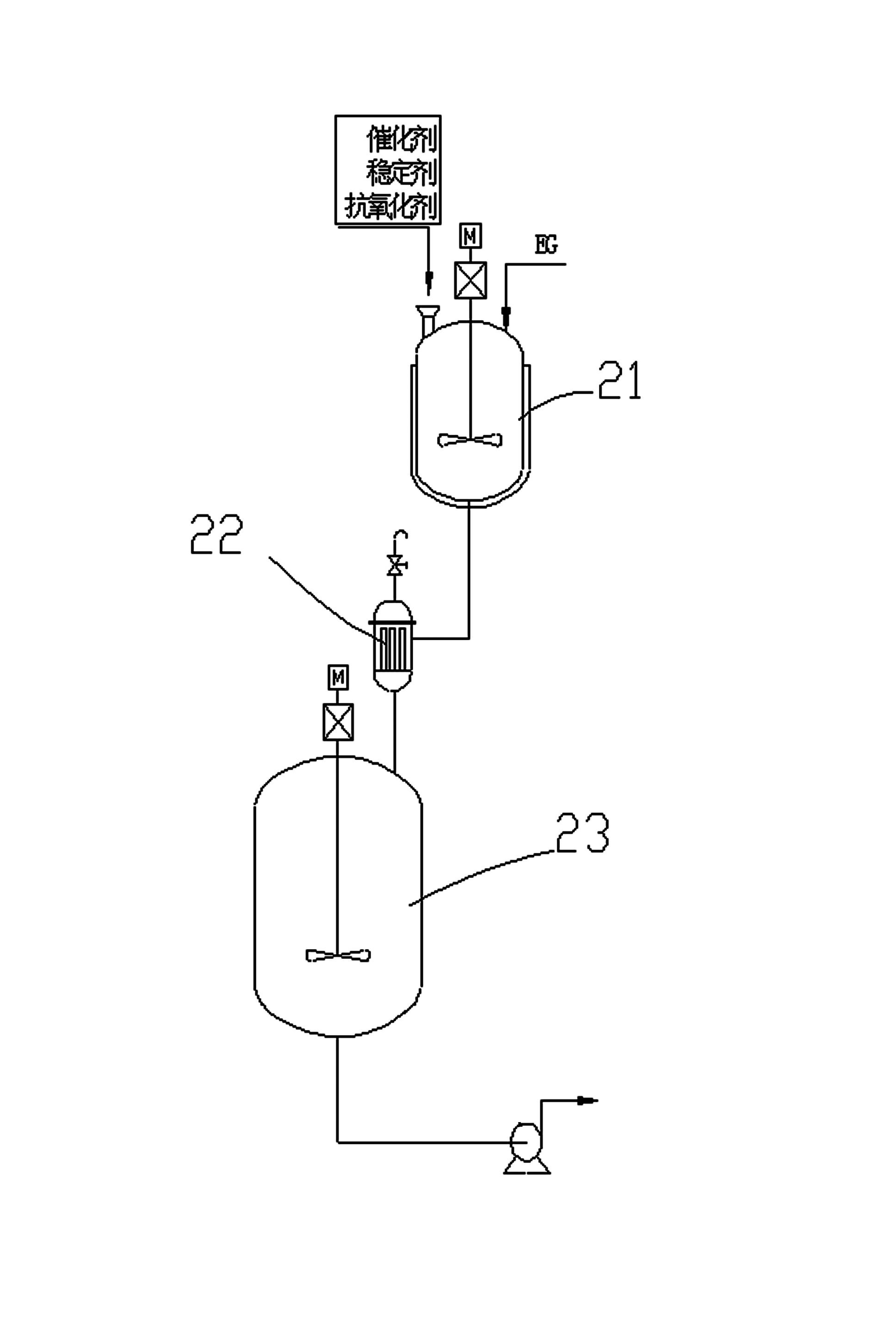

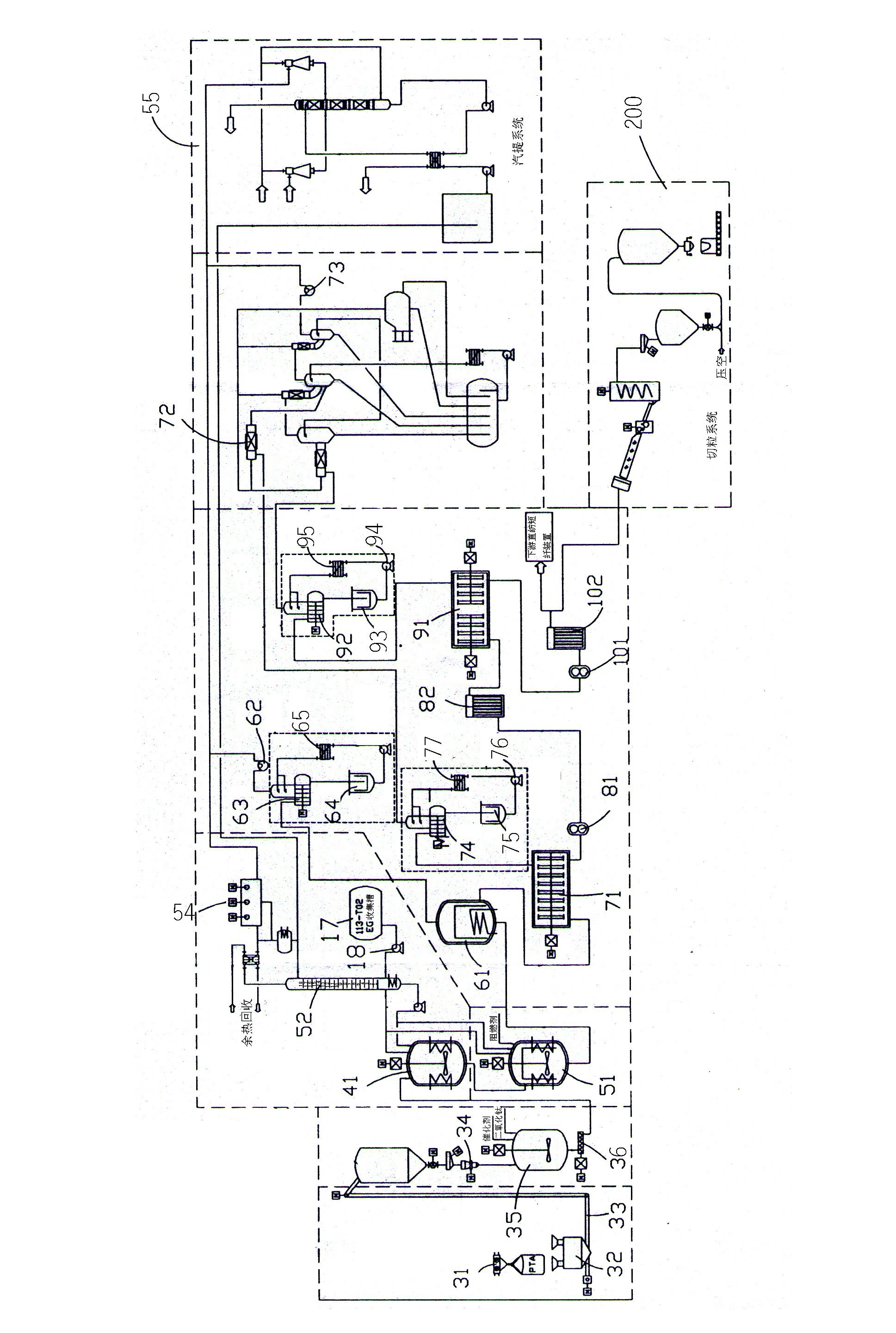

[0068] see Figure 1 to Figure 5 Shown, the manufacture technique of flame-retardant polyester fiber of the present invention, comprises the steps:

[0069] Step 1. Flame retardant preparation: CEPPA-EG esterification liquid is used as the flame retardant ; The flame retardant CEPPA-EG esterification liquid is formed by the esterification reaction of non-toxic phosphorus flame retardant 2-carboxyethylphenyl hypophosphorous acid CEPPA powder and polyester raw material EG, such as figure 1 As shown, the method is as follows: adopt batch preparation operation, first add metered ethylene glycol EG in the beating tank 11, put in the weighed flame retardant CEPPA powder under stirring state, after fully stirring and mixing evenly, use The screw pump 12 is pumped into the esterification kettle 13 to carry out the esterification reaction. The ratio is to add 5000kg of CEPPA powder for every 6500L of EG. The reaction formula is:

[0070] CEPPA+EG 90kPa, 175°C, 60min CEPPA-EG es...

Embodiment 2

[0110] The following only sets forth the differences from Example 1, mainly the difference in process parameters, and all the others refer to Example 1:

[0111] Step 1, flame retardant preparation: see embodiment 1 for the main process parameters of flame retardant preparation;

[0112] Step 2. Catalyst & auxiliary agent mixed solution preparation: The main process parameters for preparing the catalyst & auxiliary agent mixed solution are:

[0113] EG(L) SbAC3 (kg) TMP (kg) 2215 (kg) SbAC3 concentration (%wt.) TMP concentration (%wt.) 2215 Concentration (%wt.) Constant temperature (°C) Constant temperature time (h) 6265 150 35 375 2. 1 0.49 5.2 165 3

[0114] ;

[0115] Step 3, slurry preparation: wherein the main process parameters of slurry allocation are shown in Example 1:

[0116] ;

[0117] Step 4, the first stage esterification reaction: wherein the main process parameters of the first esterification system:

[0118] ...

Embodiment 3

[0145] The following only sets forth the differences from Example 1, mainly the difference in process parameters, and all the others refer to Example 1:

[0146] Step 1, Flame retardant preparation: See Example 1 for the main process parameters of flame retardant preparation ;

[0147] Step 2. Catalyst & auxiliary agent mixed solution preparation: The main process parameters for preparing the catalyst & auxiliary agent mixed solution are:

[0148] EG(L) SbAC3 (kg) TMP (kg) 2215 (kg) SbAC3 concentration (%wt.) TMP concentration (%wt.) 2215 Concentration (%wt.) Constant temperature (°C) Constant temperature time (h) 6265 150 35 375 2.0 0.47 5.0 165 3

[0149] ;

[0150]Step 3, slurry preparation: wherein the main process parameters of slurry preparation are shown in Example 1;

[0151] Step 4, the first stage esterification reaction: wherein the main process parameters of the first esterification system:

[0152] temperature...

PUM

| Property | Measurement | Unit |

|---|---|---|

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com