Silver powder for solar cell conductive silver pulp and preparation and application

A technology of solar cells and conductive silver paste, applied in transportation and packaging, metal processing equipment, etc., can solve the problems of cumbersome process, unsuitable silver powder particle size, large silver loss, etc., and achieve high activity, narrow sintering temperature range, high photoelectricity The effect of conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

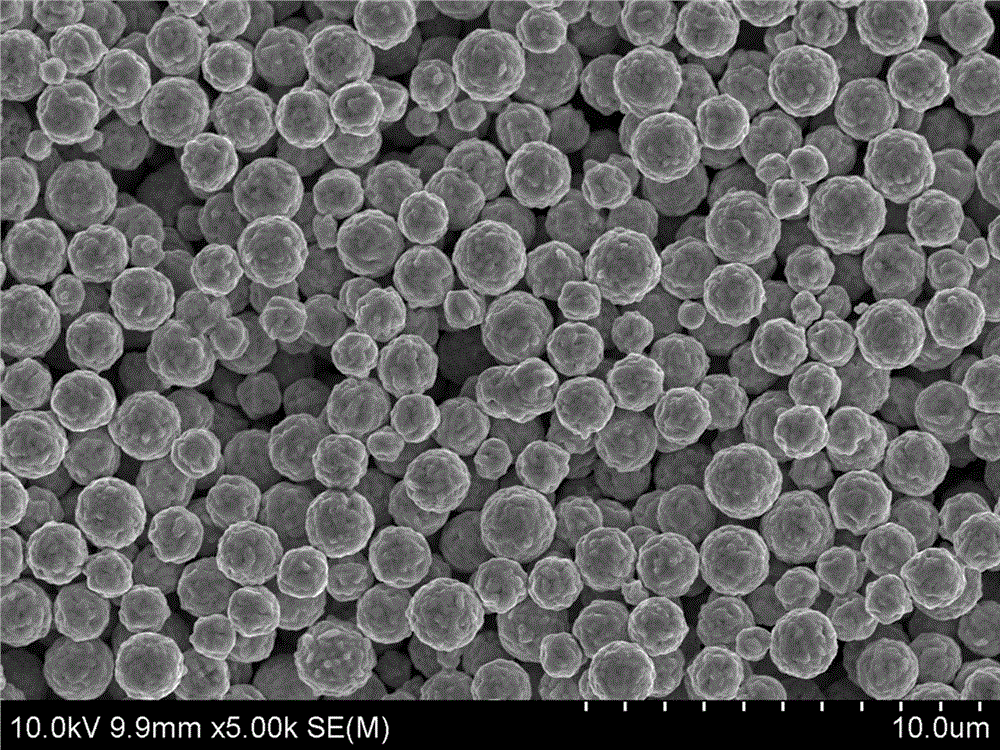

Embodiment 1

[0023] First prepare 0.5 mol / L silver nitrate solution as silver source, adjust its pH to 5 with nitric acid; secondly prepare 1.5 mol / L ascorbic acid solution, and add polyvinyl alcohol with 1% silver nitrate mass; redox reaction step by step, in The reaction temperature was 20°C, and the stirring rate was 100 r / min. First, 0.2 times the volume of the total silver source was quickly added to the reducing solution, and 10% oleic acid of the mass of silver nitrate was added; then the remaining silver source was added with Slowly add 5 ml / min to the reducing solution. During the dropping process, use ammonia water or nitric acid to control the pH of the solution to 3. After the dropping is completed, react for 30 minutes, pour out the supernatant, and wash with deionized water and absolute ethanol respectively. 3 times and dried in an oven at 60°C for 4 h.

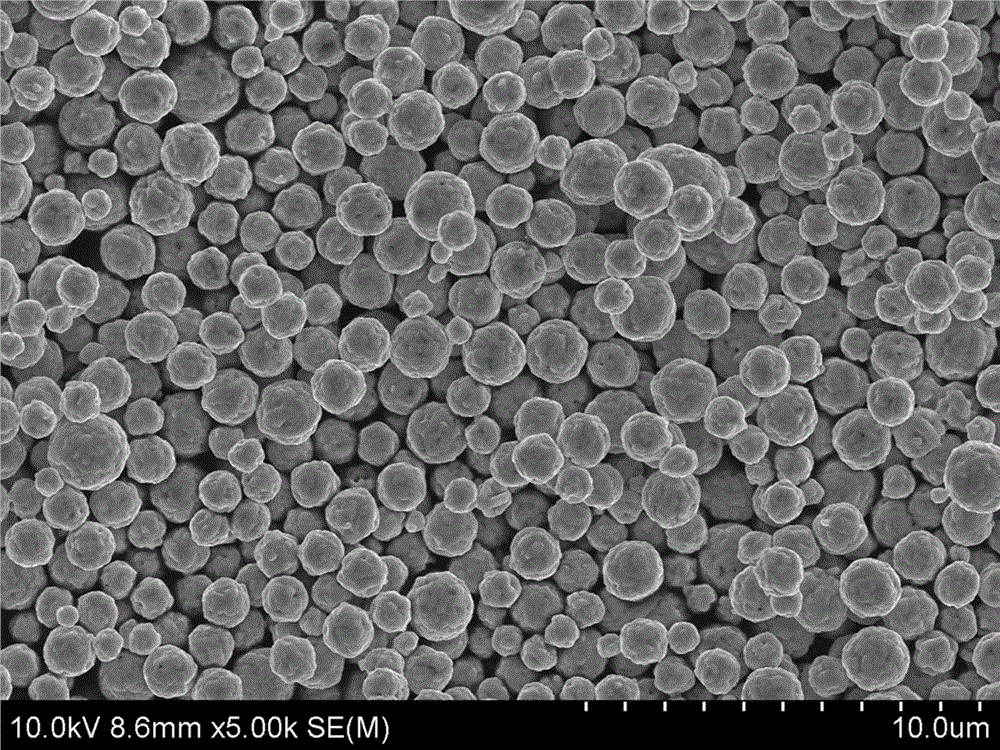

Embodiment 2

[0025] First prepare 1.0 mol / L silver nitrate solution as the silver source, adjust its pH to 1 with nitric acid; secondly prepare 3.0 mol / L ascorbic acid solution, and add gum arabic with 4% silver nitrate mass; carry out the redox reaction step by step. At a temperature of 30°C and a stirring rate of 50 r / min, 0.5 times the volume of the total silver source was quickly added to the reducing solution, and 6% oleic acid of the mass of silver nitrate was added; ml / min slowly added dropwise to the reducing solution. During the dropping process, the pH of the solution was controlled to be 4 with ammonia water or nitric acid. After the dropwise addition was completed, the reaction was continued for 30 min. and dried in an oven at 60°C for 4 h.

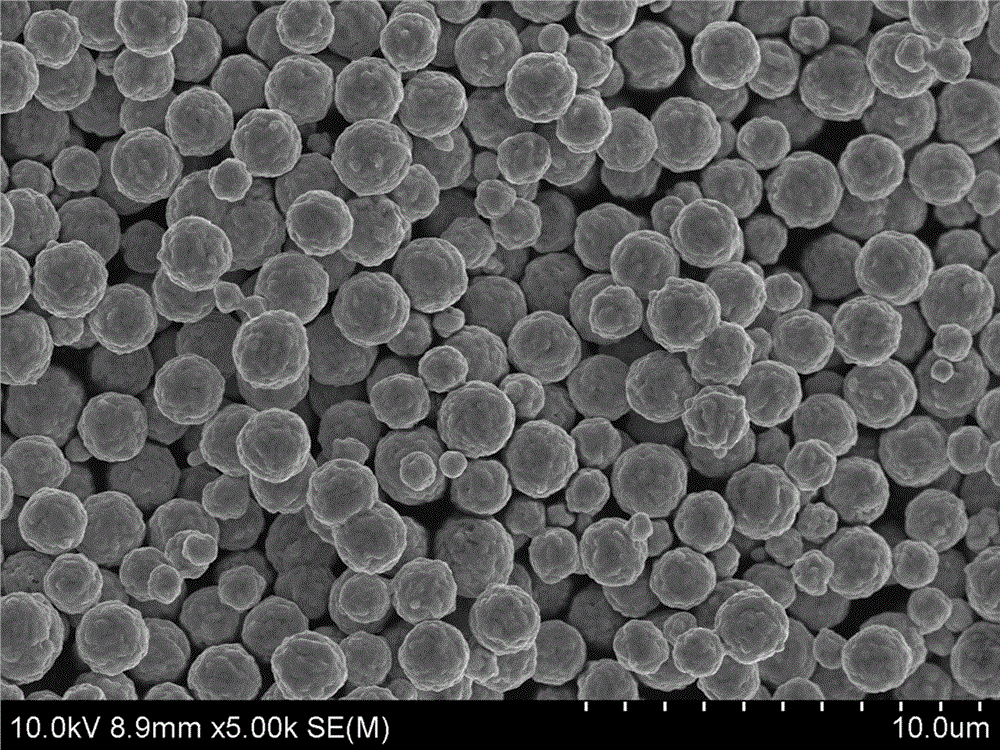

Embodiment 3

[0027] First prepare 2.5 mol / L silver nitrate solution as silver source, adjust its pH to 3 with nitric acid; secondly prepare 0.5 mol / L ascorbic acid solution, and add methyl cellulose with 10% silver nitrate mass; carry out redox reaction step by step, At a reaction temperature of 50°C and a stirring rate of 1000 r / min, quickly add 0.3 times the volume of the total silver source to the reducing solution, and add 1% oleic acid to the mass of silver nitrate; then add the remaining silver source Slowly add dropwise to the reducing solution at 1 ml / min. During the dropwise addition, use ammonia water or nitric acid to control the pH of the solution to 2. After the dropwise addition is complete, react for 30 minutes. Pour out the supernatant, and use deionized water and absolute ethanol Wash three times and dry in an oven at 60°C for 4 h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com