Internal curing process for improving performance of high strength and slight expansion concrete

A micro-expanded concrete, high-strength technology, applied in the field of internal curing technology, can solve the problems of lack of moisture in ettringite, damage to the internal structure of concrete, increase in drying shrinkage, etc. Density improvement and the effect of preventing the formation of secondary ettringite

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] An internal curing process to improve the performance of high-strength micro-expansion concrete,

[0023] After stirring the sand and stone, add cementitious material, expansion agent and super absorbent resin and stir for 30 seconds, after that, add water and water reducing agent, stir for 120 seconds and then pour,

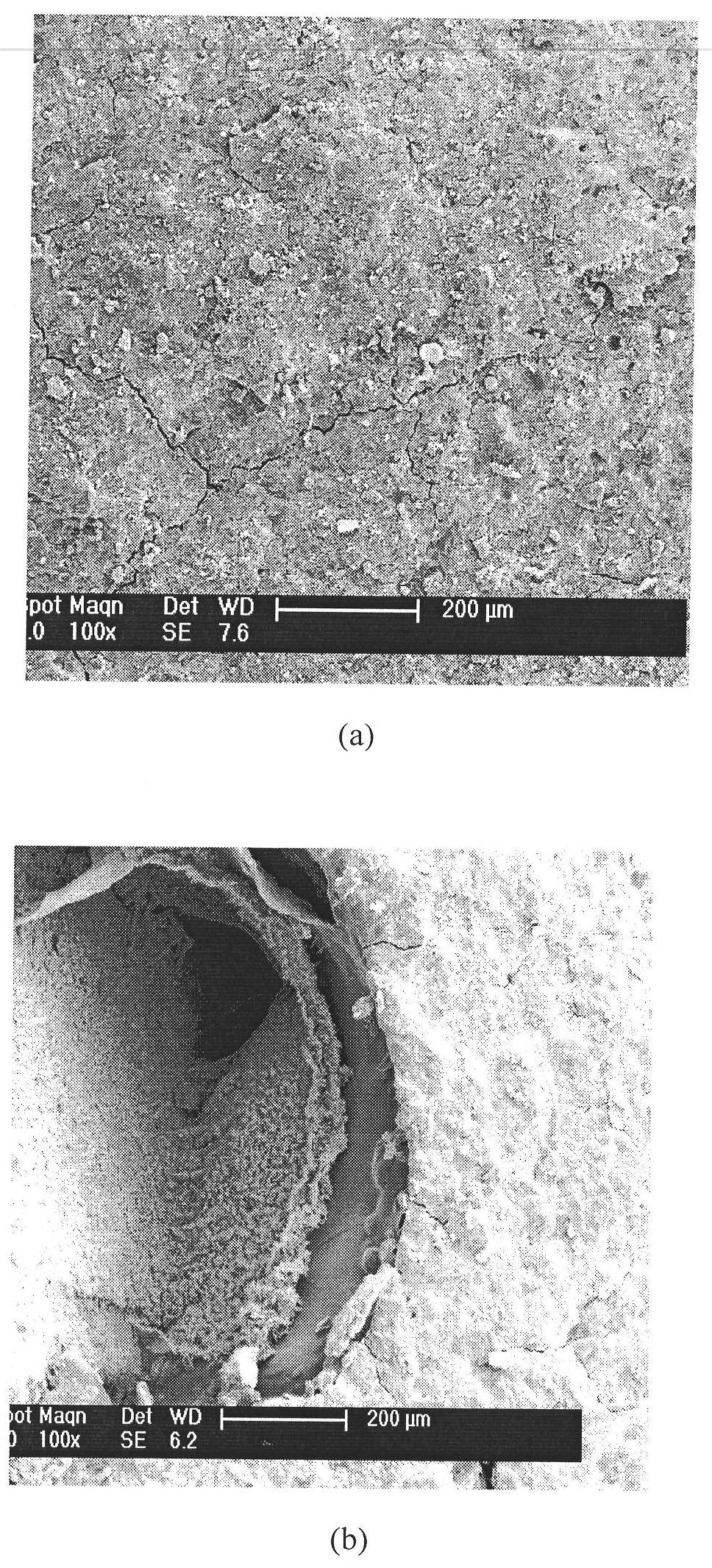

[0024] The particle size of the super absorbent resin is 80-120 μm; the water absorption rate of the super absorbent resin is 150-300 times, and the salt solution absorption capacity of the super absorbent resin is 15-40 times; the dosage range of the super absorbent resin is It is 0.15%-0.30% of the mass of the gelling material. In this embodiment, the particle diameter of the superabsorbent resin is 80, 90, 109 or 120 μm; the water absorption rate is 150, 198, 250, 270 or 300 times; The solution capacity is 15, 22, 35 or 40 times; the dosage range is 0.15%, 0.18%, 0.23% or 0.30% of the mass of the gelling material.

[0025] The working performance of t...

Embodiment 2

[0028] Preparation of C40 high-strength micro-expansion fine aggregate concrete:

[0029] Raw materials:

[0030] (1) Cement PⅡ52.5 Portland cement;

[0031] (2) Expansion agent HEA anti-crack and anti-seepage material;

[0032] (3) Fine aggregate River sand with a fineness modulus of 2.4;

[0033] (4) Water reducer PCA, polycarboxylate high-performance water reducer;

[0034] (5) SAP super absorbent resin

[0035] White polypropylene salt with a particle size of about 100 μm; for saturated Ca(OH) 2 The absorption rate of solution and tap water are shown in Table 1.1.

[0036] Table 1.1 Water absorption rate and salt absorption rate of SAP at different times

[0037] Soaking time / min

10

20

60

1440(24h)

Salt absorption rate(g / g)

33

35

41

53

Water Absorption(g / g)

124

162

184

189

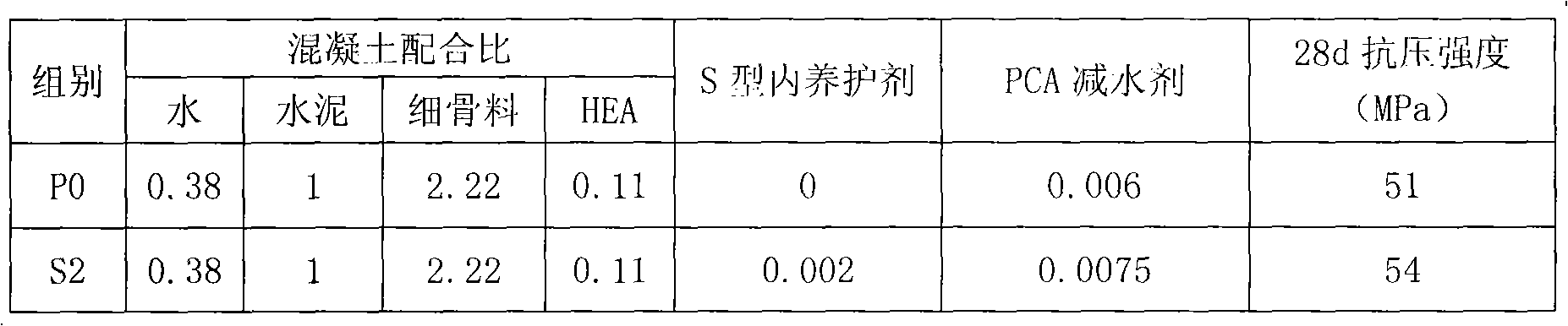

[0038] The mix ratio and performance are shown in Table 1.2-1.4.

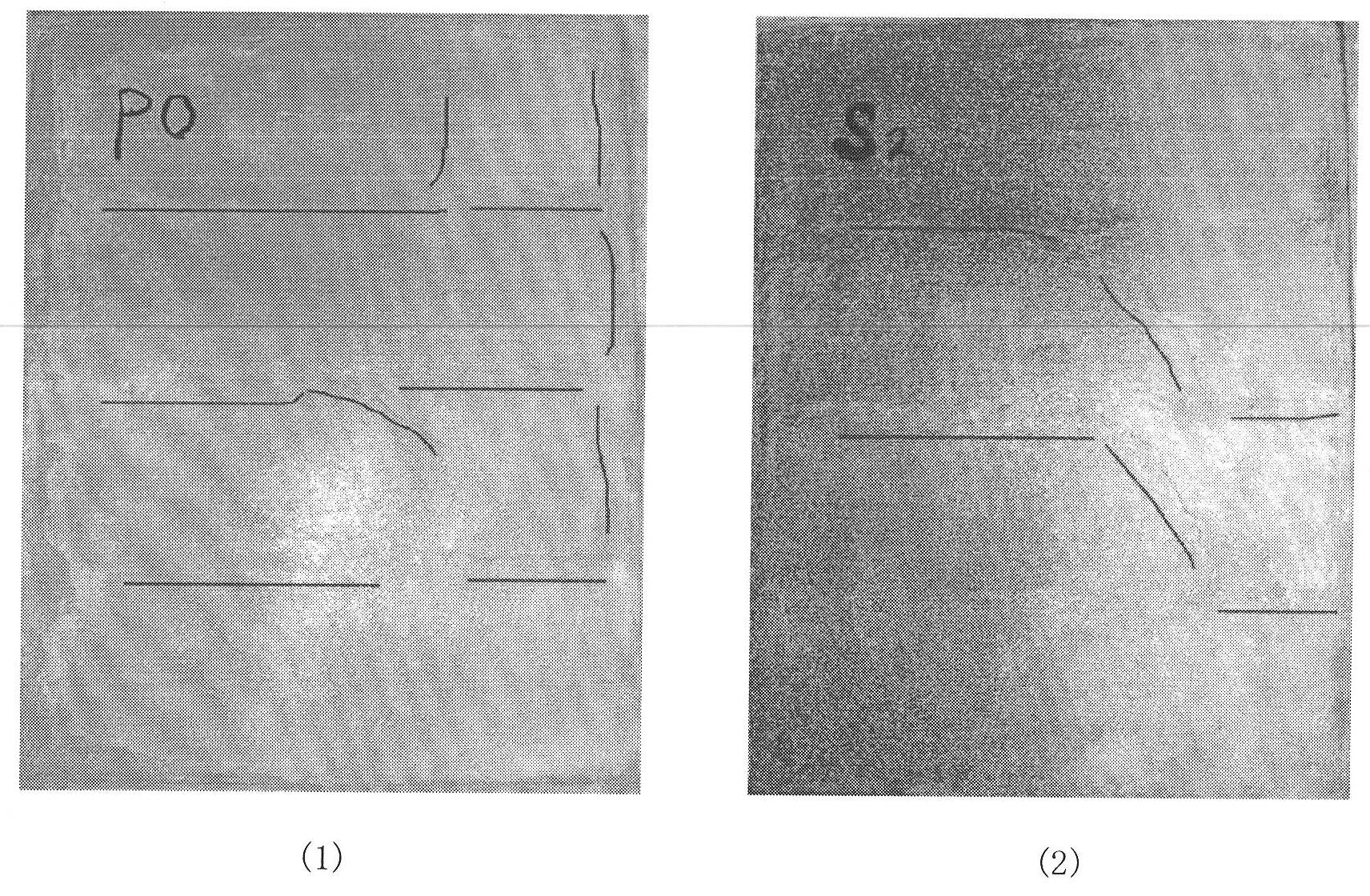

[0039] Table 1.2 Micro-expansion con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com