In situs polymerization and compatibilization blending method with microporous foaming polymer as matrix

An in-situ polymerization and polymer technology, applied in the field of in-situ polymerization and compatibilizing blending, can solve the problems of unstable performance, poor thermodynamic compatibility, and difficulty in achieving compatibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

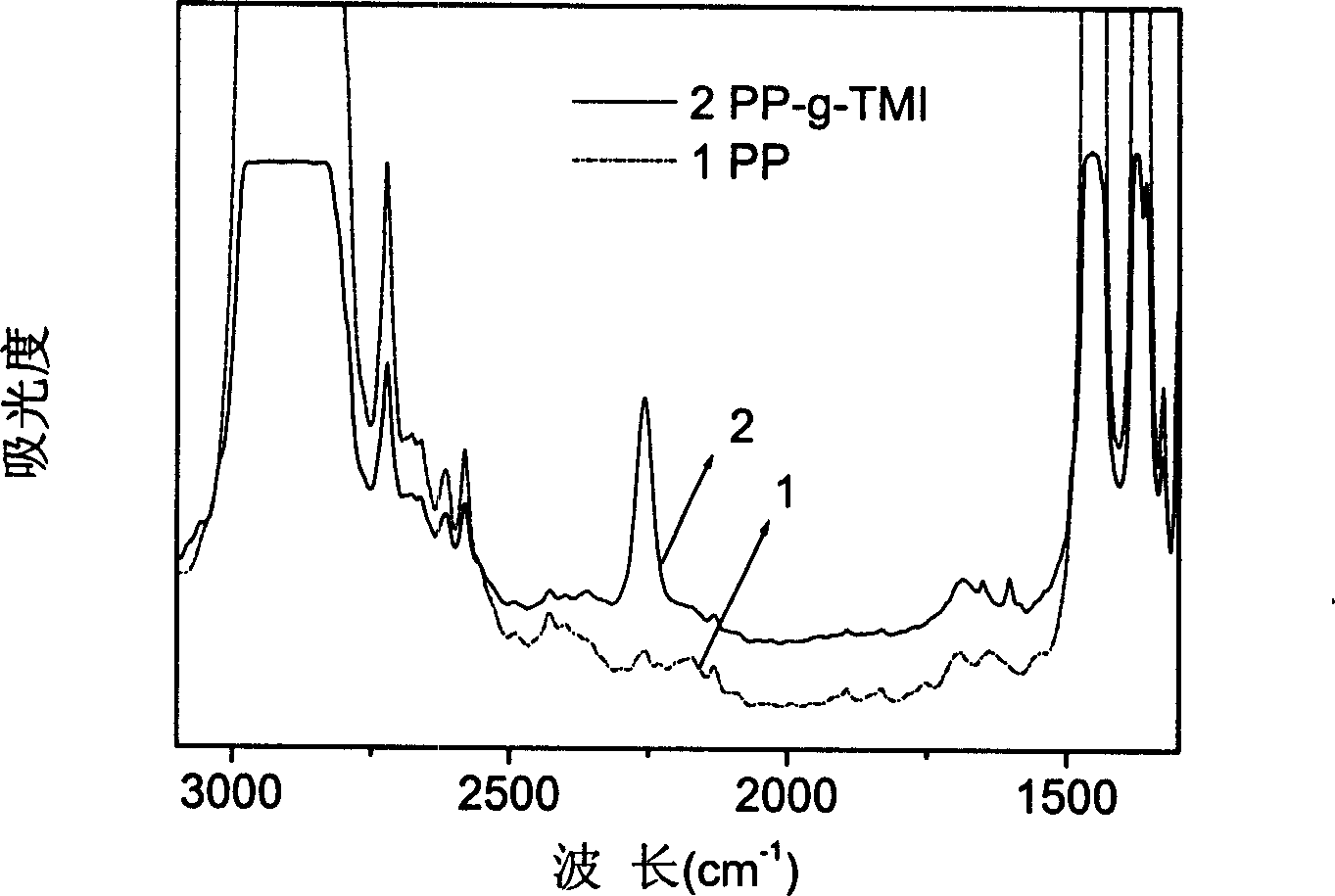

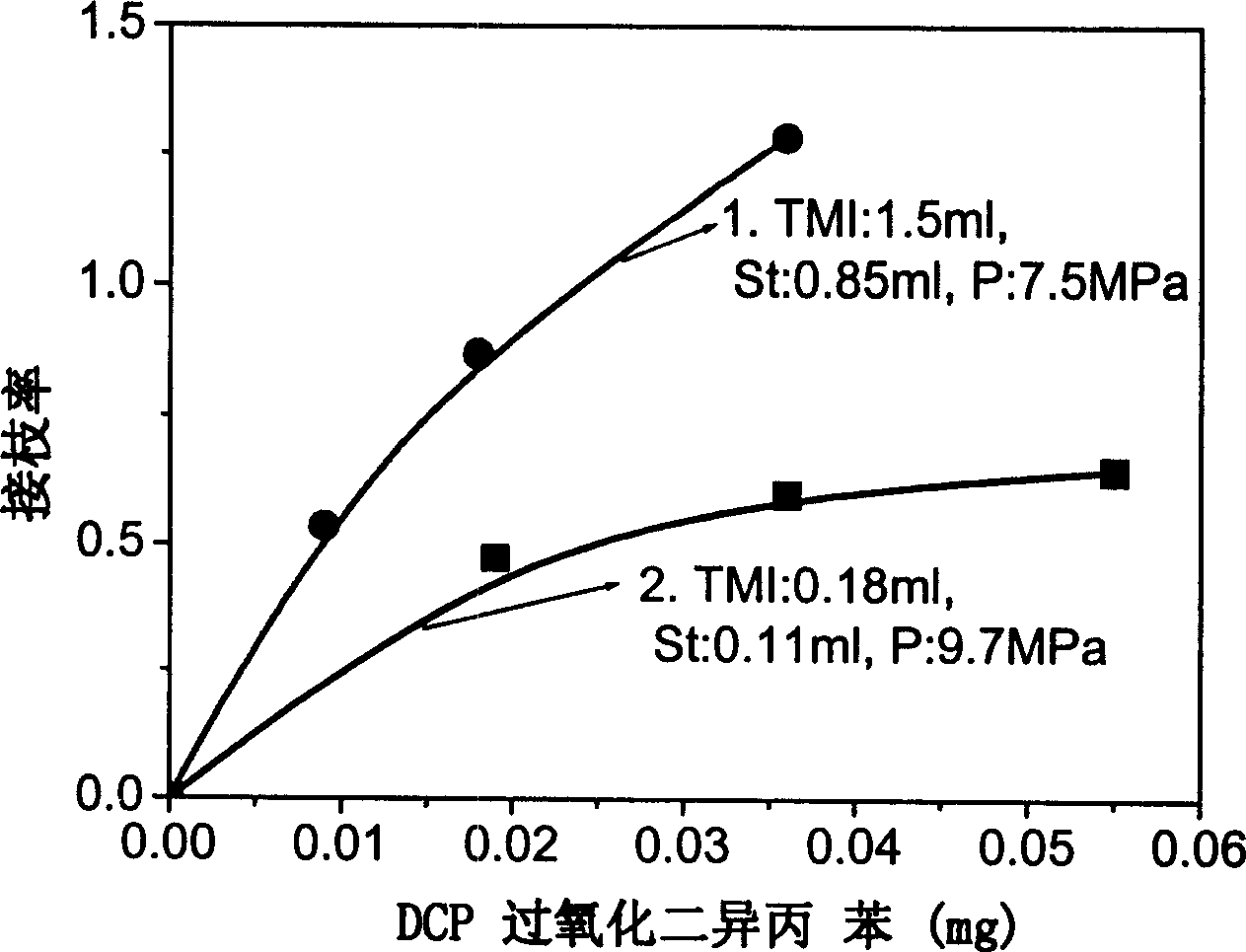

[0037] (1) Grafting reaction: 3 grams of isotactic polypropylene particles and monomer TMI with active functional groups

[0038] (3-isopropenyl-a, a-dimethylbenzene isocyanate), placed in supercritical carbon dioxide fluid under the effect of 0.036g gram initiator DCP (dicumyl peroxide), 0.85ml styrene additive 80 Swell at ℃ for 3 hours, then raise the temperature to 130 ℃, release the pressure and cool after 4 hours of reaction, wash and purify to obtain the grafted product.

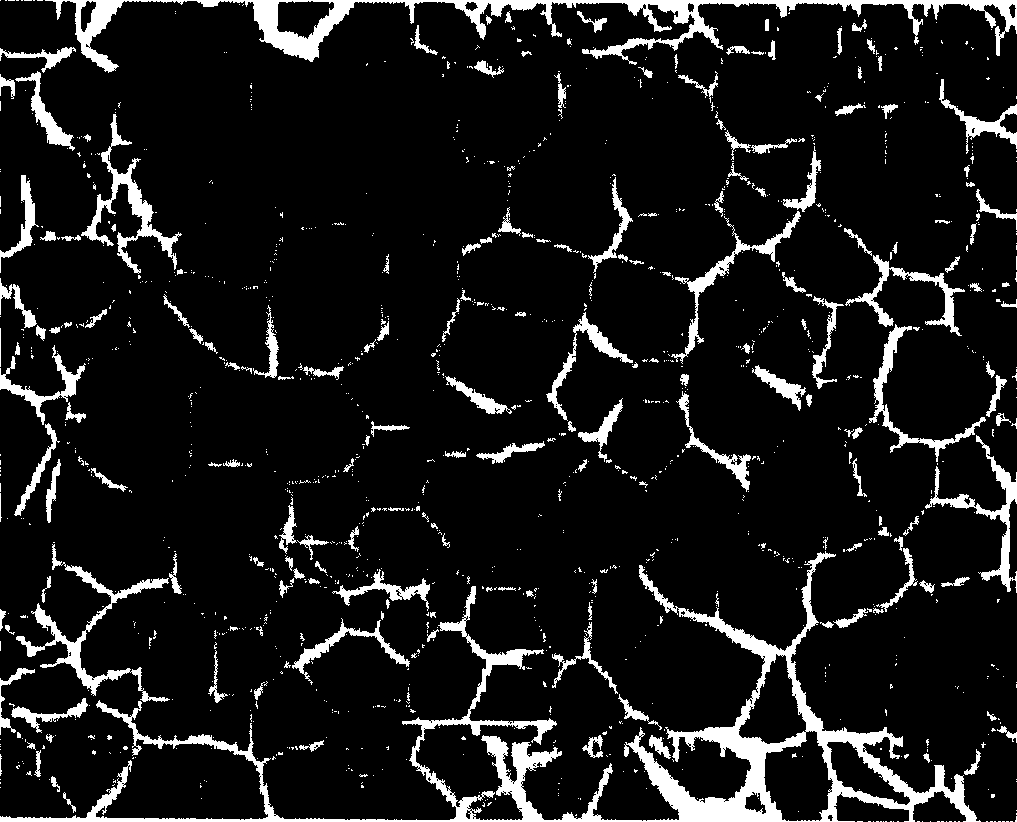

[0039] (2) Supercritical carbon dioxide foaming and assisted permeation: put 2 grams of grafted products in supercritical carbon dioxide fluid, control the temperature at 157°C, pressure at 15Mpa, swell for about 30 minutes, and quickly release the pressure to obtain foamed particles ;

[0040] Put these 2 grams of particles and 4 grams of Nylon 6 monomer - yl lactam, together with 0.24 g of sodium caprolactam catalyst in a supercritical carbon dioxide fluid, the temperature is controlled at 80 ° C, t...

Embodiment 2

[0046] (1) Grafting reaction: 3 grams of isotactic polypropylene particles and monomer TMI (3-isopropenyl-a, a-dimethylbenzene isocyanate) with active functional groups, in 0.036 g of initiator DCP (over Dicumyl oxide), 0.45ml of styrene additive, placed in supercritical carbon dioxide fluid to swell at 80°C for 3 hours, then heated up to 130°C, reacted for 4 hours, released the pressure and cooled, washed and purified to obtain the branch product.

[0047] (2) Supercritical carbon dioxide foaming and assisted permeation: put 2 grams of grafted products in supercritical carbon dioxide fluid, control the temperature at 157°C, pressure at 15Mpa, swell for about 30 minutes, and quickly release the pressure to obtain foamed particles ;

[0048] Put this 2 grams of particles and 4 grams of Nylon 6 monomer - the base lactam, together with 0.24 g of sodium caprolactam catalyst and 0.04 gram of DCP (dicumyl peroxide) activator, place a sealed container with supercritical carbon dioxi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com