Yarn twining method and yarn twining device for carbon fiber baseball

A carbon fiber yarn and carbon fiber technology, which is applied in the field of carbon fiber baseball production, can solve the problems that the strength and rigidity cannot be well guaranteed, the product wall thickness and carbon yarn texture are uneven, and the flatness of the carbon fiber layer cannot be guaranteed. The effect of simplifying raw materials and cutting time, ensuring quality, and effectively controlling product size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

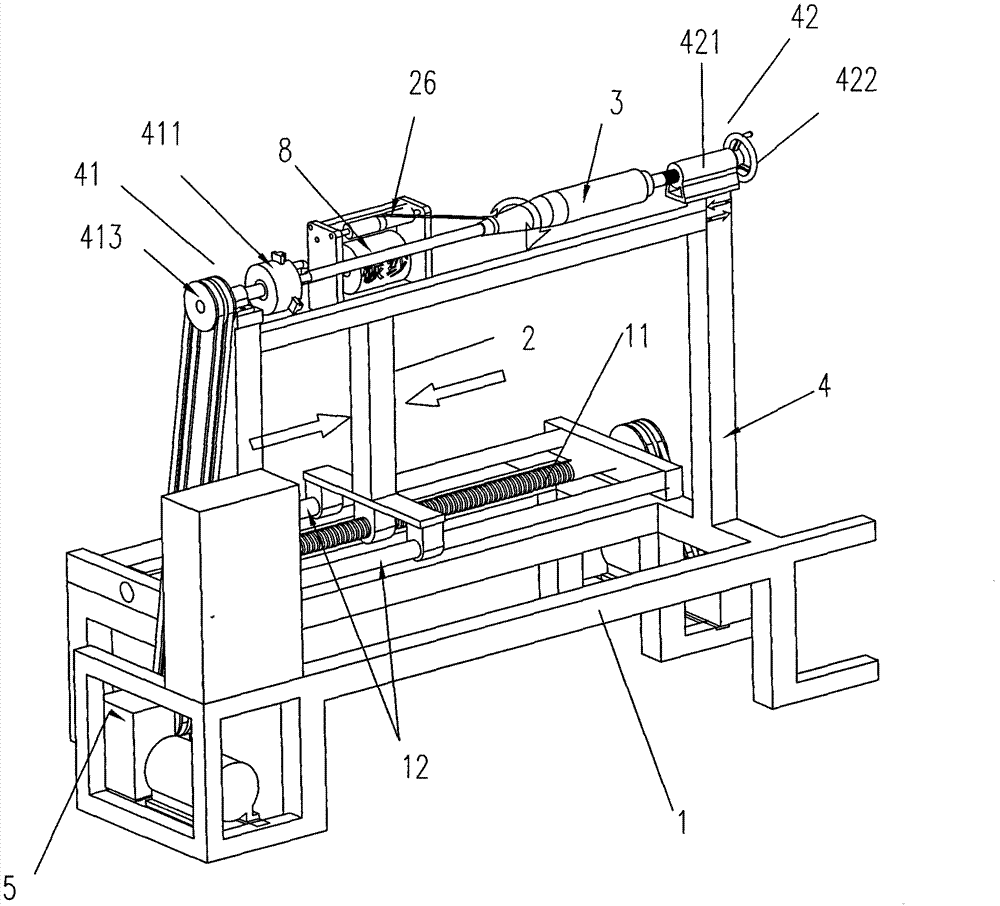

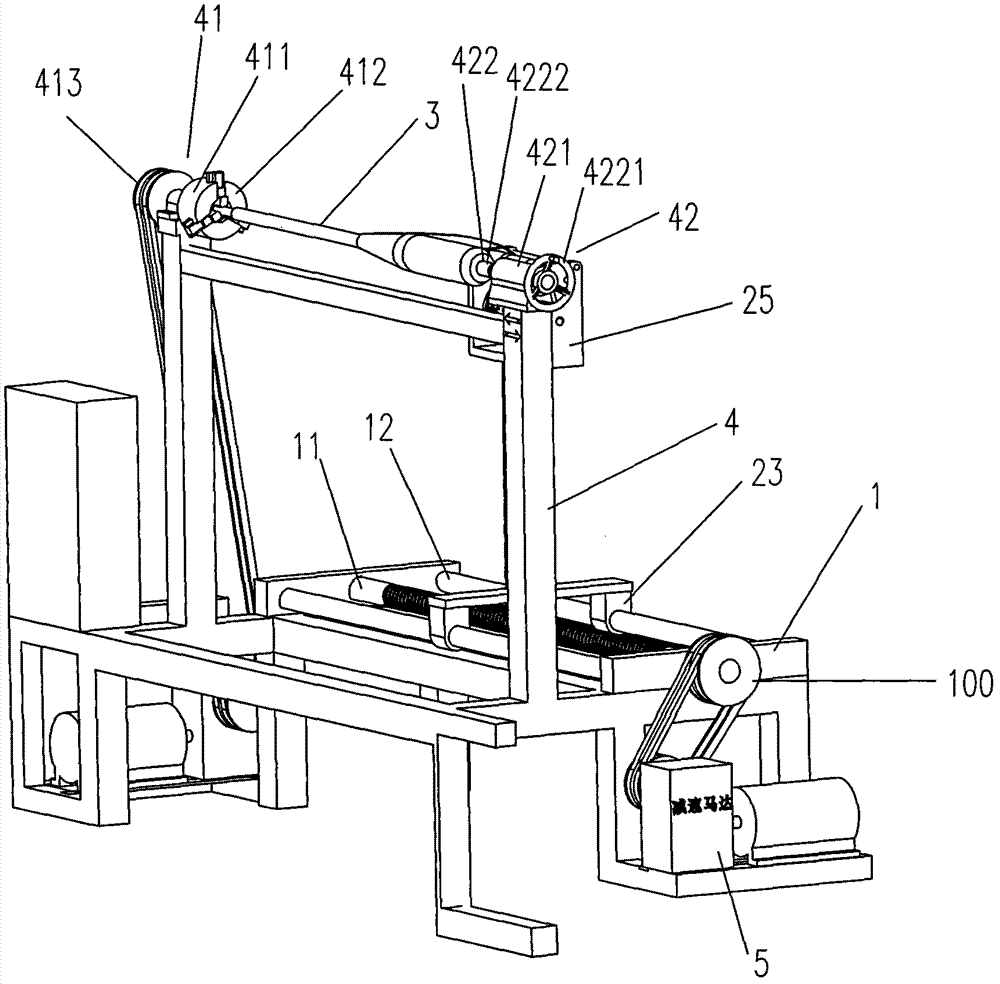

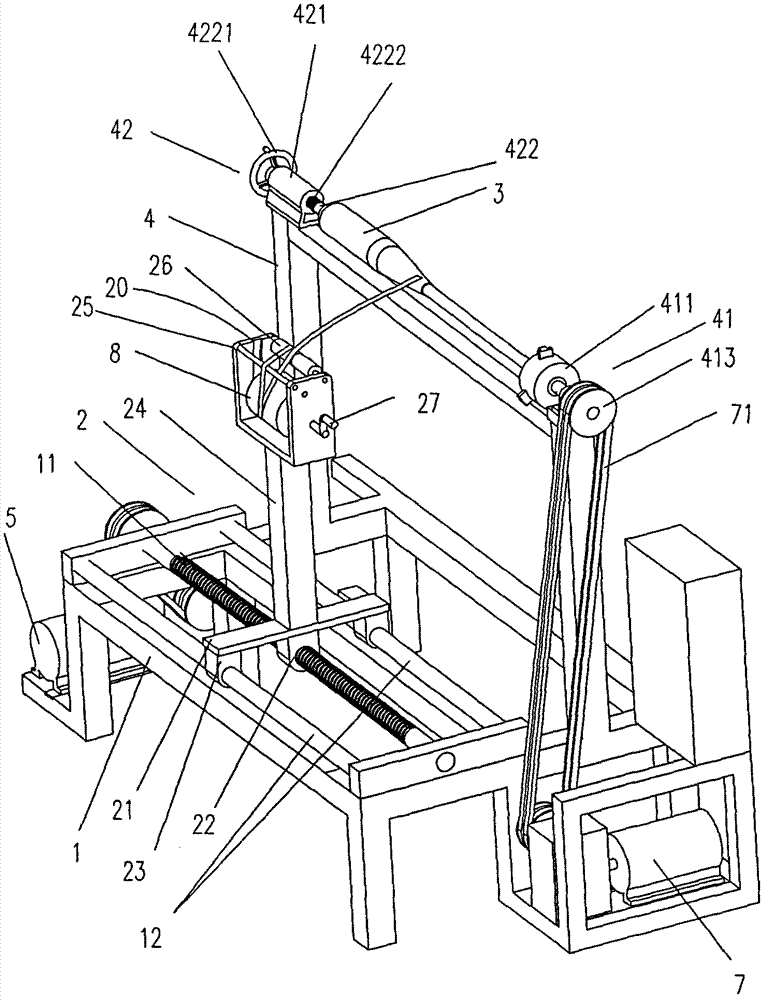

[0036] Examples, see figure 1 , figure 2 and image 3 , a kind of equipment for winding carbon fiber baseball, including workbench 1, coiling support 2 and supporting frame 4 clamping and fixing baseball mandrel 3;

[0037] The workbench 1 is provided with a threaded rod 11, one end of the threaded rod 11 is provided with a pulley 110, and a guide rail 12 parallel to it is respectively provided on both sides of the threaded rod 11, and the described threaded rod is driven by the reduction motor 5 through the pulley 110 rotate;

[0038]The bottom of the coiled yarn support 2 is provided with a crossbeam 21, and the middle of the crossbeam 21 is extended downward with a protrusion 22. The protrusion 22 is provided with an internal thread meshed with the screw rod 11, and the two sides of the protrusion 22 are respectively provided with sleeves 23. , the casing 23 is slidingly mated with the guide rail 12 of the workbench; the crossbeam 21 is provided with a column 24 upward,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com