Controllable vibrating electrode electric spark and electrolytic combined machining method for micro holes and vibrating system

A vibrating electrode and combined processing technology, which is applied in the direction of electric processing equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of high processing accuracy and surface quality, ineffective processing of micro holes, and unsuitable processing of micro holes. , to achieve the effect of reducing the gap between electrodes, ensuring the consistency of control and processing, and high speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

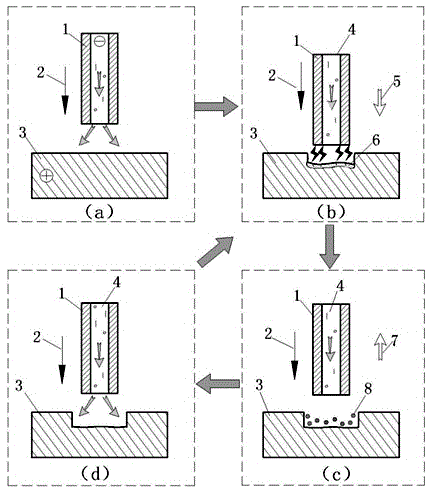

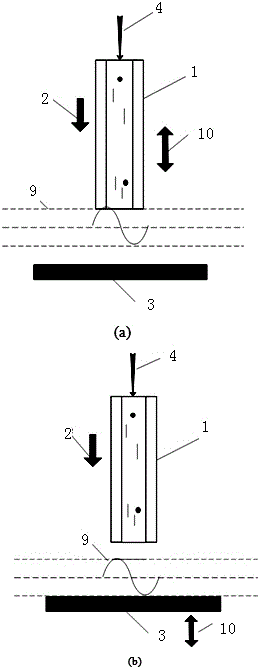

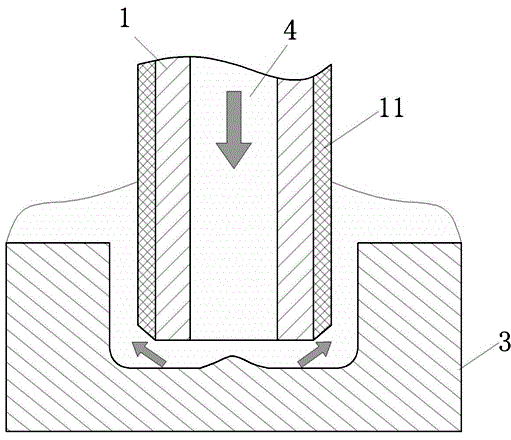

[0039] figure 1 It is the schematic diagram of the vibrating electrode EDM controllable composite machining of the present invention, in which (a) is the initial stage of processing, (b) is the stage of EDM, (c) is the stage of electrolytic processing, and (d) is the end of processing picture. It mainly includes tool electrode 1, feed direction 2, workpiece electrode 3, working fluid 4, positive vibration 5, heat-affected layer 6, negative vibration 7, and dissolved product 8. During processing, the tool electrode is connected to the negative pole, the workpiece is connected to the positive pole, and the two poles are connected to the high-frequency pulse power supply. In the working fluid circulation system, the working fluid is divided into two paths through the electromagnetic reversing valve 27, one path communicates with the inside of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com