Bismuth ferrite nano fiber material and preparation method thereof

A technology of nanofibers and bismuth ferrite, which is applied in fiber processing, chemical instruments and methods, artificial filaments of inorganic raw materials, etc., can solve the problems of low quantum efficiency, high recombination rate of photogenerated electrons and holes, and low utilization rate of solar energy and other issues, to achieve the effects of high quantum efficiency, excellent photocatalytic performance, and high utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

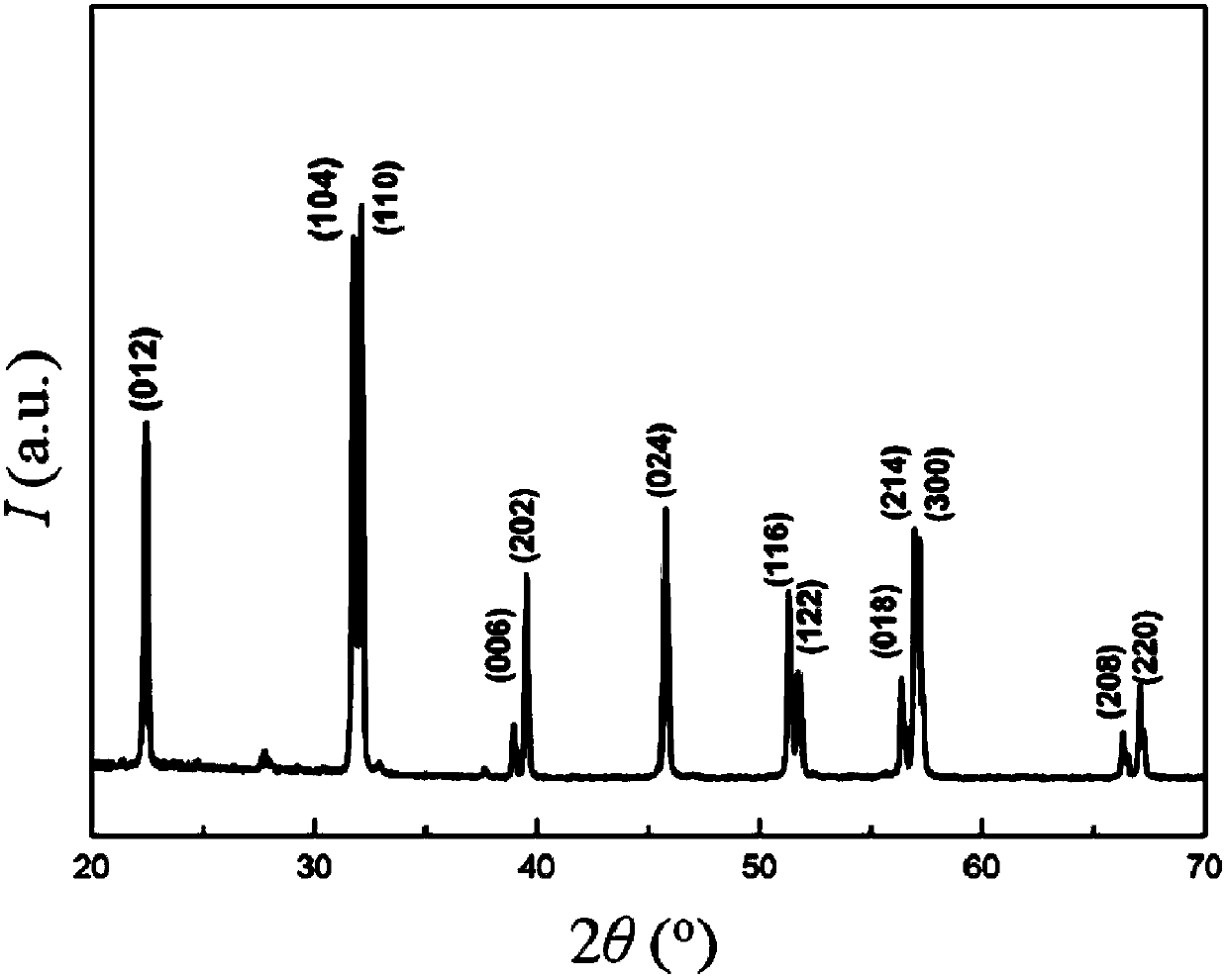

[0029] Example 1, BiFeO 3 Preparation of Nanofibrous Materials and Detection of Photocatalytic Activity

[0030] 1. BiFeO 3 Preparation of Nanofibrous Materials

[0031] 1. Bismuth nitrate pentahydrate (Bi(NO 3 ) 3 ·5H 2 O) and iron nitrate nonahydrate (Fe(NO 3 ) 3 9H 2 O) Add 20ml of N,N-dimethylformamide (DMF, N , N-dimethylformamide), stirred at room temperature for about half an hour until completely dissolved, the solution was colorless and transparent, then added 12.0mmol (2.522g) citric acid (C 6 h 8 o 7 ·H 2 O), after stirring for 1.5 hours, a yellow transparent sol containing iron nitrate and bismuth nitrate was obtained. Then add 2.076 grams of polyvinylpyrrolidone (PVP, M=1300000) to make the final mass percentage concentration 8%, stir for 2 hours to fully mix, and then let it stand for 24 hours to obtain a uniform and viscous precursor with an iron ion concentration of 0.2mol / L body solution.

[0032]2. Transfer the above precursor solution into a 10...

Embodiment 2

[0036] Example 2, BiFeO 3 Preparation of Nanofibrous Materials and Detection of Photocatalytic Activity

[0037] 1. BiFeO 3 Preparation of Nanofibrous Materials

[0038] 1. Bismuth nitrate pentahydrate (Bi(NO 3 ) 3 ·5H 2 O) and iron nitrate nonahydrate (Fe(NO 3 ) 3 9H 2 O) According to the molar ratio of 1.05:1 (i.e. 8.4 mol or 2.453 grams of bismuth nitrate pentahydrate, 8.0 mol or 3.232 grams of iron nitrate nonahydrate), add it to 20 ml of tetrahydrofuran (THF), stir at room temperature for about half an hour to Dissolve completely, the solution is colorless and transparent, then add 24.0mmol (5.043g) citric acid (C 6 h 8 o 7 ·H 2 O), after stirring for 1.5 hours, a yellow transparent sol containing iron nitrate and bismuth nitrate was obtained. Then add 1.966 grams of polyvinyl alcohol (PEG, M=66000~83600) to make the final mass percentage concentration 4%, stir for 5 hours and mix well, then let it stand for 24 hours to obtain a uniform and viscous precursor w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com