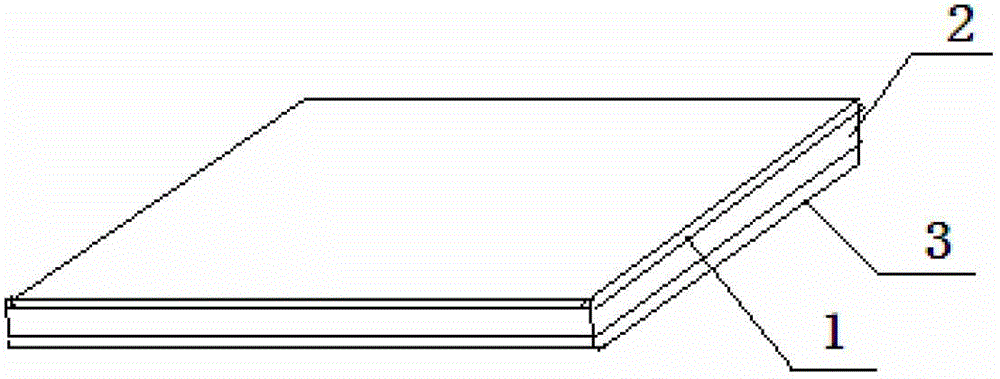

Hot-rolled stainless steel-aluminium-stainless steel composite board production method and application

A stainless steel plate and production method technology, applied in metal rolling, metal rolling, metal processing equipment and other directions, can solve the problem that the metallurgical recombination rate is difficult to reach 100%, the technical indicators cannot meet the customer's requirements, and the melting point and specific gravity are too different. Large and other problems, to achieve the effect of light weight, low cost and low compressive coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] The finished hot-rolled stainless steel-aluminum-stainless steel clad plate with a thickness of 1.5mm.

[0043] Among them: 304 stainless steel plates with a thickness of 0.3mm for both plates A and C, and 1050 pure aluminum plates with a thickness of 1.5mm for plate B. Soak in dilute hydrochloric acid solution with a concentration of 10% for 10 minutes to clean the remaining oxide layer on the surface of boards A and C. At the same time, soak board B in NaoH solution with a mass concentration of 15% for 10 minutes to clean the residual oxide layer on the surface of the board, and then use high-pressure water Rinse the three boards A, B, and C; secondly, dry the three boards A, B, and C at a temperature of 100-200°C for 5-10 minutes; thirdly, align the three boards A, B, and C Carry out four-corner riveting and fixing; then put the riveted three plates in an annealing furnace that has been heated to 300-650°C, and heat for 10-30min, then take it out, and put it in quick...

Embodiment 2

[0045] Finished hot-rolled stainless steel-aluminum-stainless steel clad plate with a thickness of 3.2mm:

[0046] Among them: 201 stainless steel plates with a thickness of 1.0mm for plates A and C, and 1050 pure aluminum plates with a thickness of 2.0mm for plate B. Its actual operation method is the same as that of Example 1, except that the heating time is correspondingly increased by 5-10 minutes on the original basis. When When the reduction rate reaches 20%, the plate thickness of the composite product can reach 3.2mm;

Embodiment 3

[0048] Finished hot-rolled stainless steel-aluminum-stainless steel clad plate with a thickness of 5.0mm:

[0049] Among them: 316L stainless steel plates with a thickness of 1.2mm for A and C plates, and 1050 pure aluminum plates with a thickness of 3.8mm for B plate. When the reduction rate reaches 20%, the thickness of the composite finished sheet can reach 5.0mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com