Preparation method for stannous methyl amino iodide-titanium dioxide visible light catalytic material

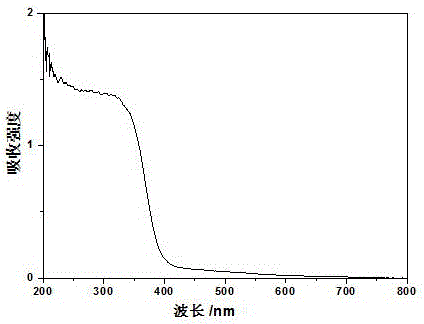

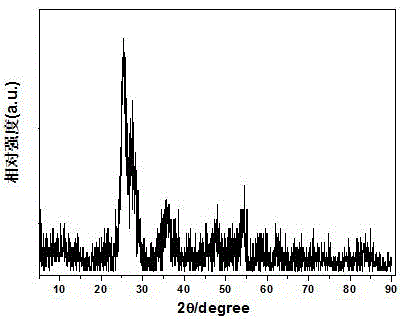

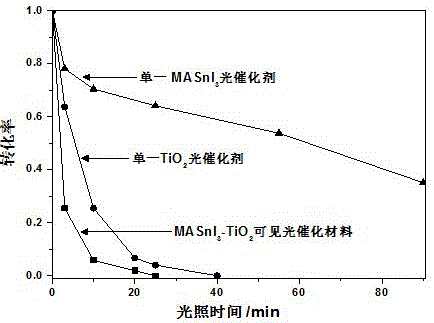

A technology of stannous iodide and methylamino is applied in the field of preparation of methylamino stannous iodide-titanium dioxide visible light catalytic materials, and can solve the problems of poor control of coating uniformity, inaccurate component stoichiometry, and increased Synthetic material cost and other issues, to achieve the effect of improving visible light catalytic activity, wide light response range and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031]In this embodiment, the preparation method of methylamino tin iodide-titanium dioxide visible light catalytic material, the steps of the method are as follows:

[0032] (1), the preparation of methyl ammonium iodide (MAI), comprises the following steps:

[0033] 30mL methylamine (CH 3 NH 2 ) alcohol solution and 30mL hydrogen iodide (HI) aqueous solution were mixed, magnetically stirred, and reacted at 0°C for 3 hours to obtain a mixed solution; the mixed solution was rotary evaporated to obtain a white precipitate; the white precipitate was dissolved in a mixed solvent of ethanol and ether Carry out recrystallization operation, put the precipitate after recrystallization in 60 ℃ of vacuum oven and dry 24h, obtain the methyl ammonium iodide (MAI) of white dryness, use in the preparation of above-mentioned methyl ammonium iodide (MAI) Methylamine (CH 3 NH 2 ) alcoholic solution can be a commercially available product, and its purity is an analytically pure reagent;

...

Embodiment 2

[0049] Embodiment 2: The method of this embodiment 2 is basically the same as that of the above-mentioned embodiment 1, the difference is that step 4 described in this embodiment 2 is specifically as follows:

[0050] The methylamino tin iodide-titanium dioxide (MASnI) described in step 4 3 -TiO 2 ) The preparation of visible light catalytic material comprises the following steps:

[0051] (4-1). The methylamino tin iodide (MASnI) synthesized in the 3rd step of 0.637g 3 ) and 2.8mL tetrabutyl titanate (TBOT) were added to 50mL n-hexane to form a mixed solution, nitrogen (N 2 ) into the mixed solution so as to remove the air in the mixed solution, and the mixed solution was heated, stirred and refluxed at 70°C for 8 hours to form a suspension;

[0052] (4-2). Step (4-2) in the second embodiment and step (4-2) in the first embodiment;

[0053] (4-3). Step (4-3) in the second embodiment and step (4-3) in the first embodiment;

Embodiment 3

[0057] The third embodiment is basically the same as the method in the first embodiment above, the difference is that step 4 described in the third embodiment is specifically as follows:

[0058] The methylamino tin iodide-titanium dioxide (MASnI) described in step 4 3 -TiO 2 ) The preparation of visible light catalytic material comprises the following steps:

[0059] (4-1). The step (4-1) in the third embodiment is the same as the step (4-1) in the first embodiment;

[0060] (4-2). Step (4-2) in the third embodiment is the same as step (4-2) in the first embodiment;

[0061] (4-3). Add the pure solid obtained in step (2) to 50mL deionized water, fully hydrolyze under the condition of magnetic stirring, and then filter and wash to form a precipitate, and put the precipitate into a vacuum drying oven , dried at 80°C for 12 hours to obtain dry solid powder;

[0062] (4-4). The step (4-4) in the third embodiment is the same as the step (4-4) in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com