Preparation of silver/cadmium sulfide-nanoparticle-comodified titanium dioxide nanotube array

A technology of nanotube arrays and titanium dioxide, which is applied in the field of preparation of silver and cadmium sulfide nanoparticles co-modified titanium dioxide nanotube arrays, can solve the problems of unsatisfactory photocatalysis and little improvement in photoelectric performance, and achieve easy control of reaction parameters and experimental results. The effect of low equipment requirements and high photoelectric conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A method for co-modifying titanium dioxide nanotube arrays with silver and cadmium sulfide nanoparticles, comprising the steps of:

[0029] (1) Ultrasonic cleaning and degreasing of high-purity titanium sheets (purity ≥ 99.5%, with a thickness of 0.25 mm): ultrasonically clean the titanium sheets in acetone, methanol, and isopropanol for 10 minutes;

[0030] Removal of natural oxide film: put the cleaned titanium sheet into mixed acid (HF:HNO 3 : deionized water=1:4:5, volume ratio) in ultrasonic for 10s to remove the oxide layer;

[0031] Primary anodizing: Put the titanium sheet after removing the oxide film into the anodizing device, add 0.5wt.%NH 4The ethylene glycol solution of F and 3vol.% deionized water is the electrolyte, the oxidation voltage is 60V, the temperature of the electrolyte is room temperature, and the oxidation time is 1h;

[0032] Remove the primary oxide layer: then the prepared TiO 2 The layer was taken out, and the Ti substrate was exposed b...

Embodiment 2

[0039] The specific operations of each step in this example are the same as those in Example 1, the only difference being that in step (3), the number of times of modification of the titanium dioxide nanotubes modified with Ag nanoparticles by CdS nanoparticles is changed to 7 cycles.

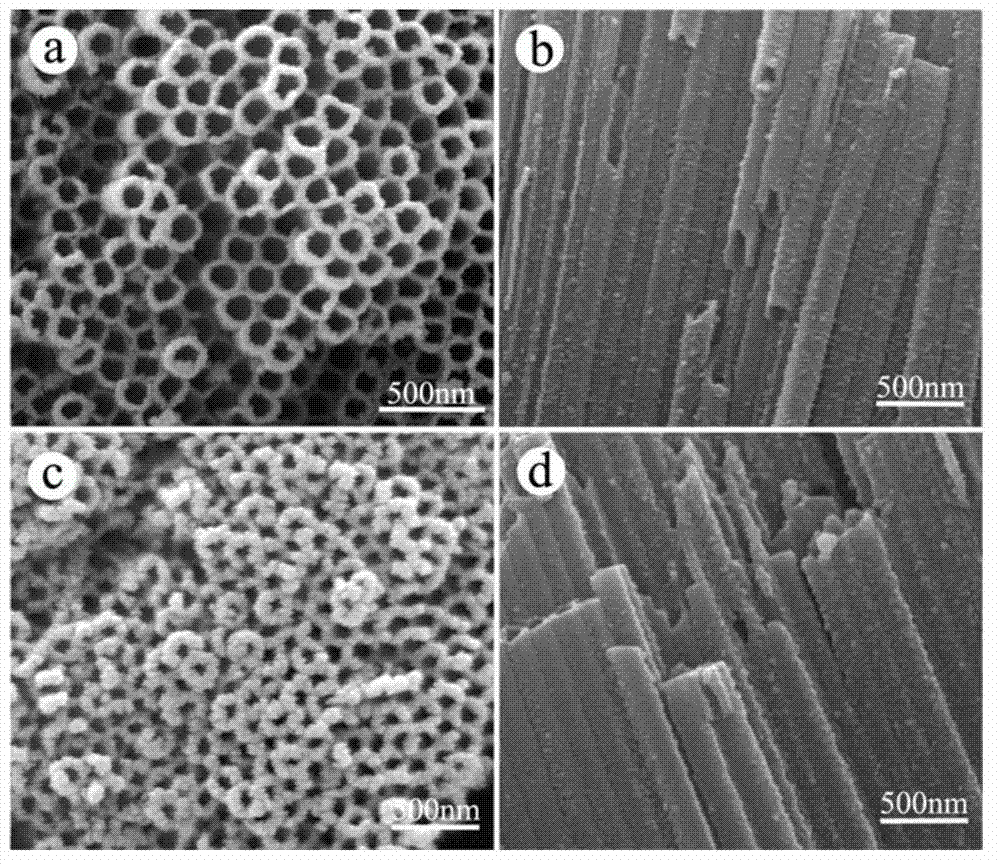

[0040] figure 1 For different cycles of Ag in Examples 1 and 2, CdS nanoparticles co-modify TiO 2 Nanotube Array FESEM. It can be seen from the figure that after 3 cycles of Ag and CdS nanoparticle co-modification in step (3), it can be clearly observed that there are nanoparticles on the nozzle and inner wall, and the distribution is uniform without agglomeration, but the surface deposition The amount is relatively small. However, when increasing the number of operating cycles in step (3), after 7 cycles, TiO 2 A large number of Ag and CdS nanoparticles appeared on the surface and inner wall of the nanotube, and they agglomerated together, almost closing the tube opening.

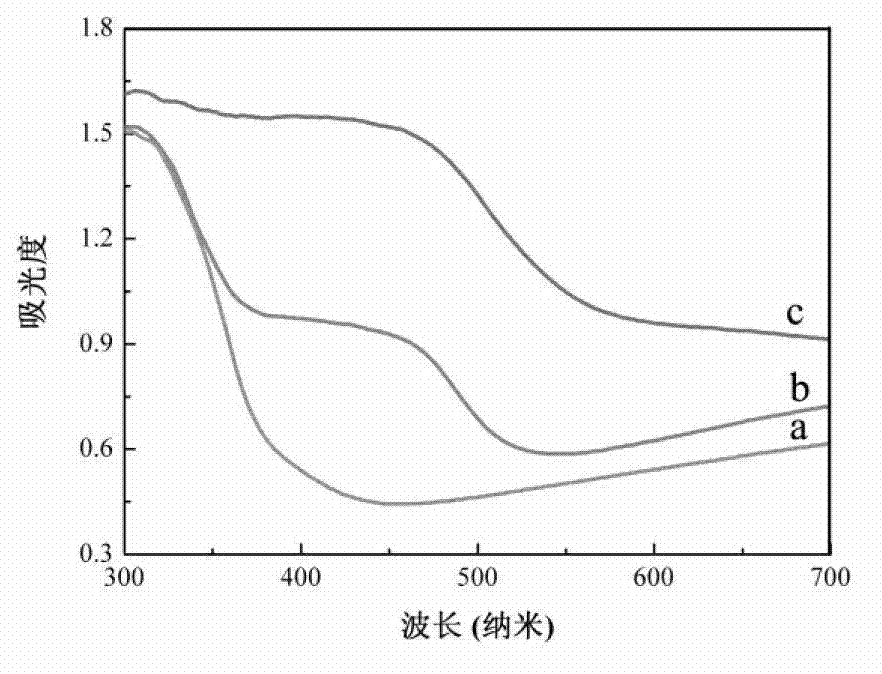

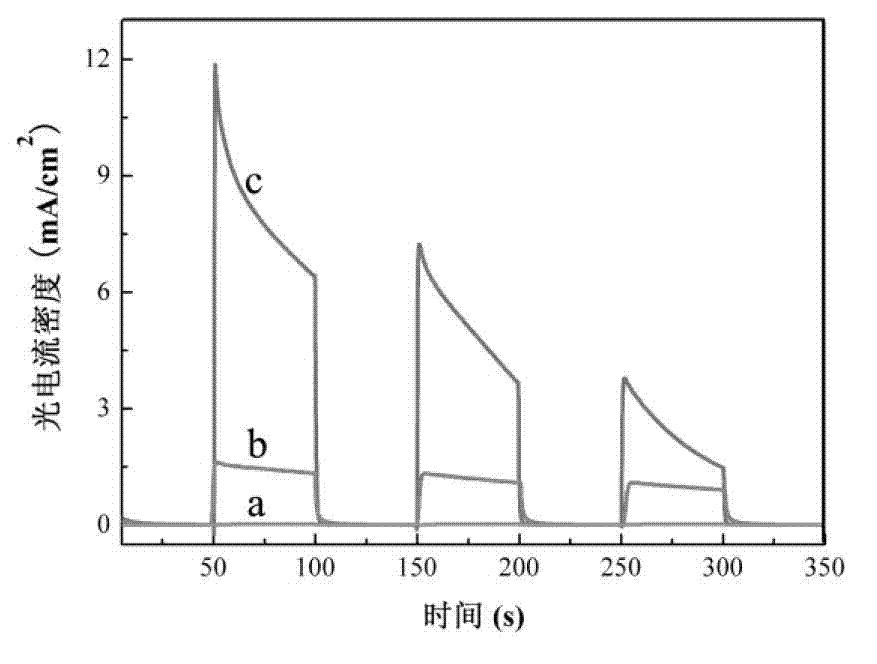

[0041] figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com