Preparation method for front electrode of solar cell

A technology of solar cells and front electrodes, applied in the field of solar photovoltaic utilization, can solve the problems of poor light utilization efficiency of solar cells, increase the series resistance of solar cells, and difficulty in increasing the height of fine grids, so as to achieve narrow width and improve conversion efficiency. , the effect of reducing losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

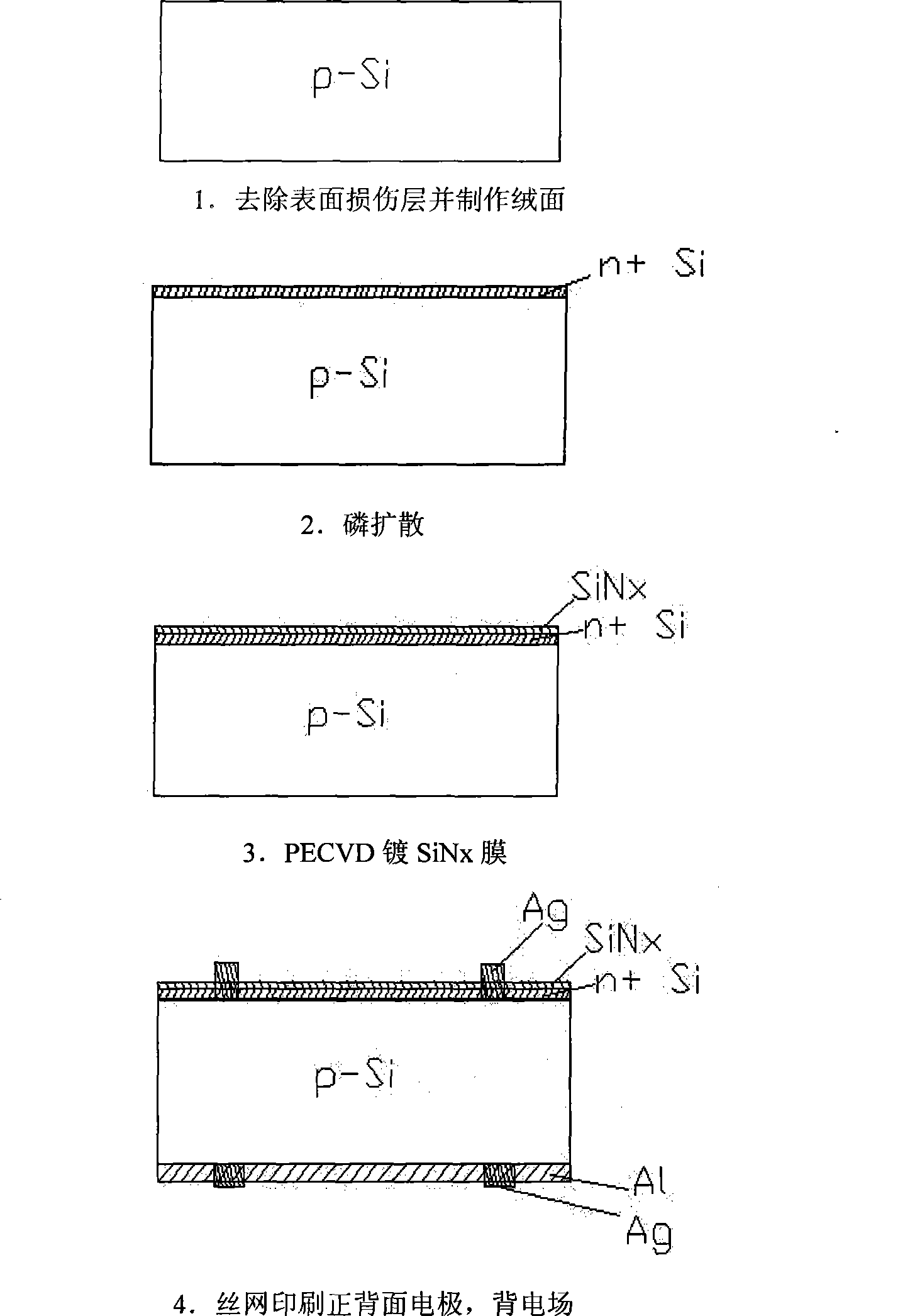

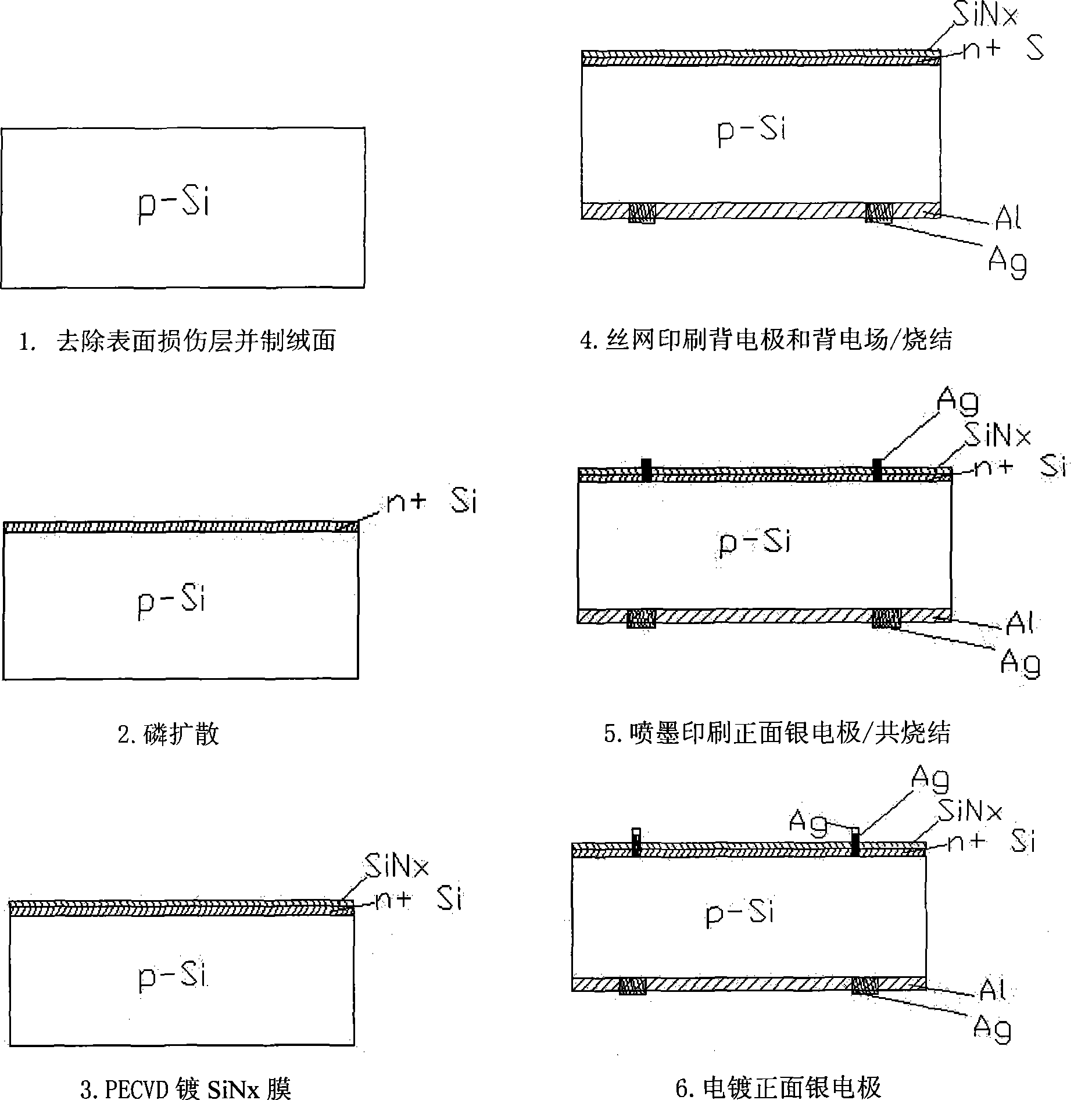

[0014] like figure 2 Shown, the technological process of the embodiment of the present invention 1 is:

[0015] ①Remove the damaged layer and textured surface of the silicon wafer;

[0016] ② in POCl 3 Diffusion of P in the atmosphere to form n + diffusion layer;

[0017] ③Using PECVD process to coat SiNx anti-reflection film on the front;

[0018] ④ Screen printing back electrode and back electric field;

[0019] ⑤Using inkjet printing to prepare silver electrodes for front grid lines;

[0020] ⑥ Electroplating a layer of silver on the front electrode by means of electroplating;

[0021] ⑦Sintering in the sintering furnace.

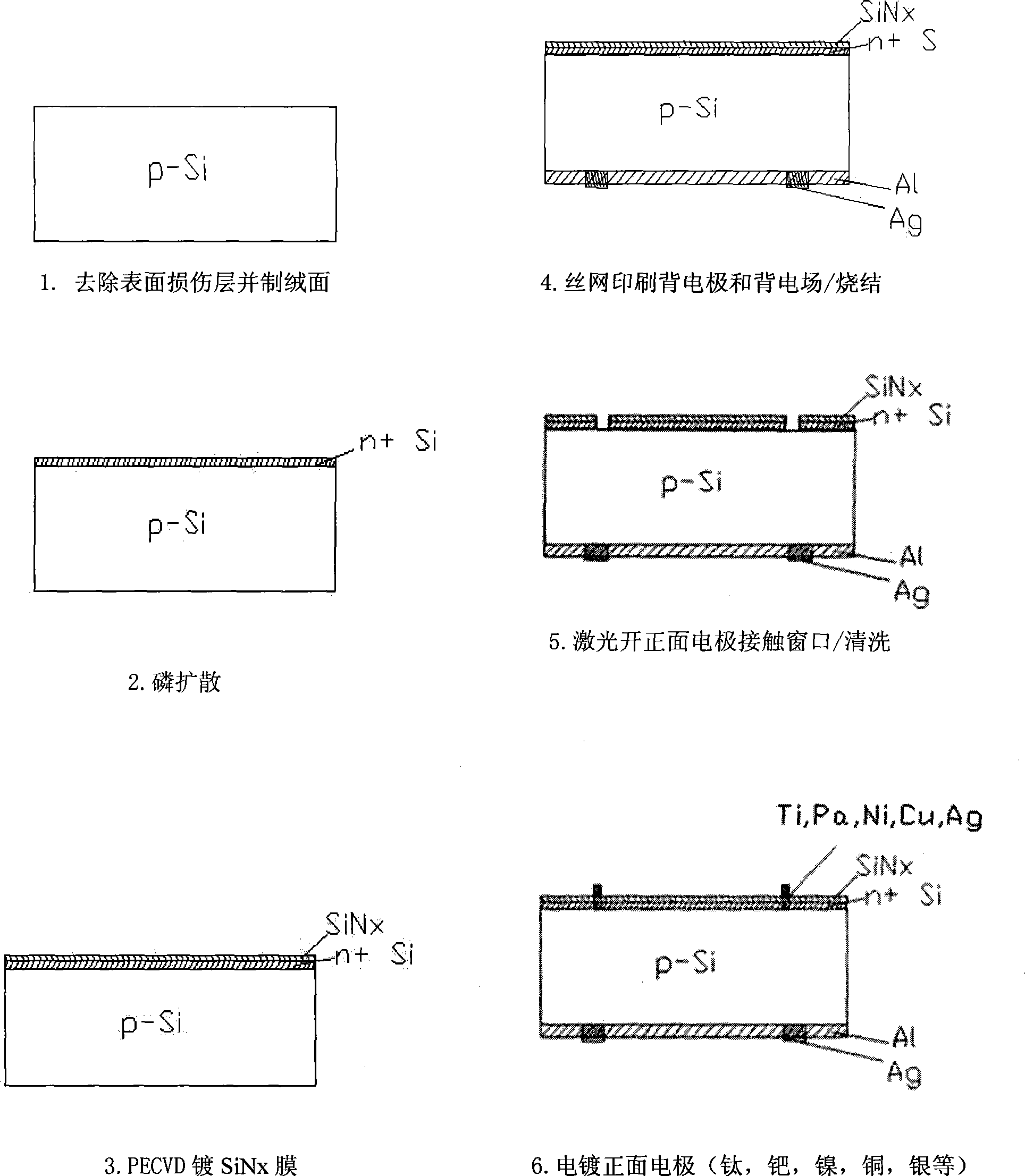

[0022] like image 3 Shown, the technological process of the embodiment of the present invention 2 is:

[0023] ①Remove the damaged layer and textured surface of the silicon wafer;

[0024] ② in POCl 3 Diffusion of P in the atmosphere to form n + diffusion layer;

[0025] ③Using PECVD process to coat SiNx anti-reflection film on the front; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com