High-conductivity lead-free silver paste used for crystalline silicon solar cell and preparation method thereof

A technology of solar cells and high conductivity, applied to conductive materials dispersed in non-conductive inorganic materials, cable/conductor manufacturing, circuits, etc., can solve problems such as the photoelectric conversion efficiency of series resistors that cannot reach the sintering temperature of nano-silver paste , to achieve the effect of improving photoelectric conversion efficiency, high conductivity, and reducing series resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

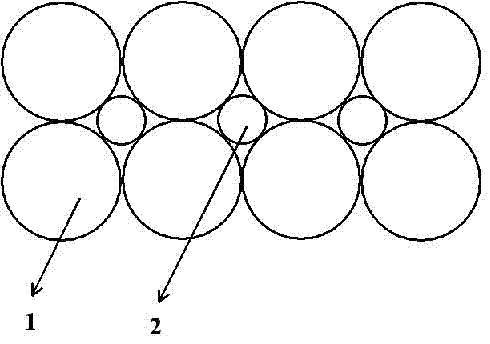

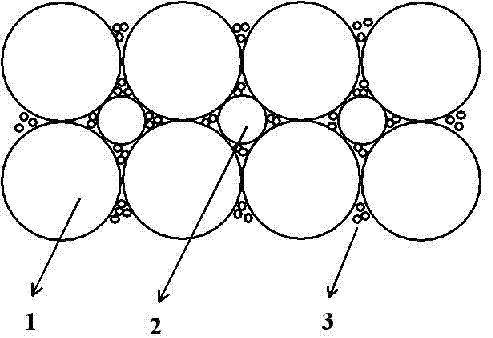

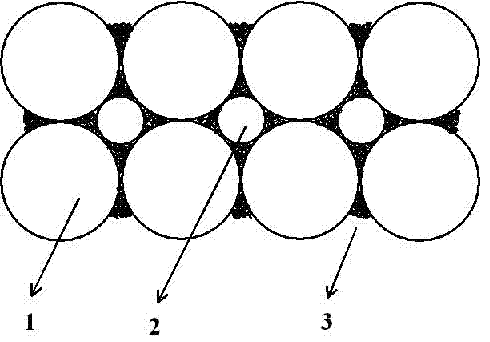

Method used

Image

Examples

example 1

[0036] 1. The components of the glass adhesive are weighed according to the following weight ratio: Bi 2 o 3 70%; B 2 o 3 20%; SiO 2 10%, followed by mixing the above components evenly and placing them in a high-temperature muffle furnace. The temperature is controlled at 1200°C and kept for 60 minutes, and then the molten glass system is quenched and ball milled;

[0037] 2. The components of the inorganic additives are weighed according to the following weight ratio: Al 2 o 3 20%; MnO 2 20%; MgO 20%; CaO 20%; Ta 2 o 5 20%, and mix the above components evenly in a glass mortar;

[0038] 3. The organic solvent and the organic additive are mixed uniformly with a weight ratio of 5: 1, wherein α-terpineol and 2-ethoxyethyl acetate in the organic solvent are uniformly mixed with a weight ratio of 2: 1;

[0039] 4. After weighing 8% and 62% of micron silver powder with an average particle size of 2.5 μm and 6 μm and 5% of nano silver powder with a particle size of 30...

example 2

[0045] 1. The components of the glass adhesive are weighed according to the following weight ratio: Bi 2 o 3 70%; B 2 o 3 20%; SiO 2 10%, followed by mixing the above components evenly and placing them in a high-temperature muffle furnace. The temperature is controlled at 1200°C and kept for 60 minutes, and then the molten glass system is quenched and ball milled;

[0046] 2. The components of the inorganic additives are weighed according to the following weight ratio: Al 2 o 3 20%; MnO 2 20%; MgO 20%; CaO 20%; Ta 2 o 5 20%, and mix the above components evenly in a glass mortar;

[0047] 3. The organic solvent and the organic additive are mixed uniformly with a weight ratio of 5: 1, wherein α-terpineol and 2-ethoxyethyl acetate in the organic solvent are uniformly mixed with a weight ratio of 2: 1;

[0048] 4. 8% and 57% of micron silver powder with an average particle size of 3.5 μm and 8.5 μm and 10% of nano-silver powder with a particle size of 30nm, 3% of gl...

example 3

[0054] 1. The components of the glass adhesive are weighed according to the following weight ratio: Bi 2 o 3 70%; B 2 o 3 20%; SiO 2 10%, followed by mixing the above components evenly and placing them in a high-temperature muffle furnace. The temperature is controlled at 1200°C and kept for 60 minutes, and then the molten glass system is quenched and ball milled;

[0055] 2. The components of the inorganic additives are weighed according to the following weight ratio: Al 2 o 3 20%; MnO 2 20%; MgO 20%; CaO 20%; Ta 2 o 5 20%, and mix the above components evenly in a glass mortar;

[0056] 3. The organic solvent and the organic additive are mixed uniformly with a weight ratio of 5: 1, wherein α-terpineol and 2-ethoxyethyl acetate in the organic solvent are uniformly mixed with a weight ratio of 2: 1;

[0057] 4. 8.5% and 61.5% of micron silver powder with an average particle size of 3 μm and 7 μm and 5% of nano silver powder with a particle size of 20nm, 3% of gla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com