Low-temperature sintered microwave medium ceramic material and preparation method thereof

A technology of microwave dielectric ceramics and low-temperature sintering, which is applied in the direction of ceramics and inorganic insulators, which can solve the problems of manufacturing cost and cycle increase, complex process, etc., and achieve low sintering temperature, simple chemical composition and preparation process, and excellent microwave dielectric performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

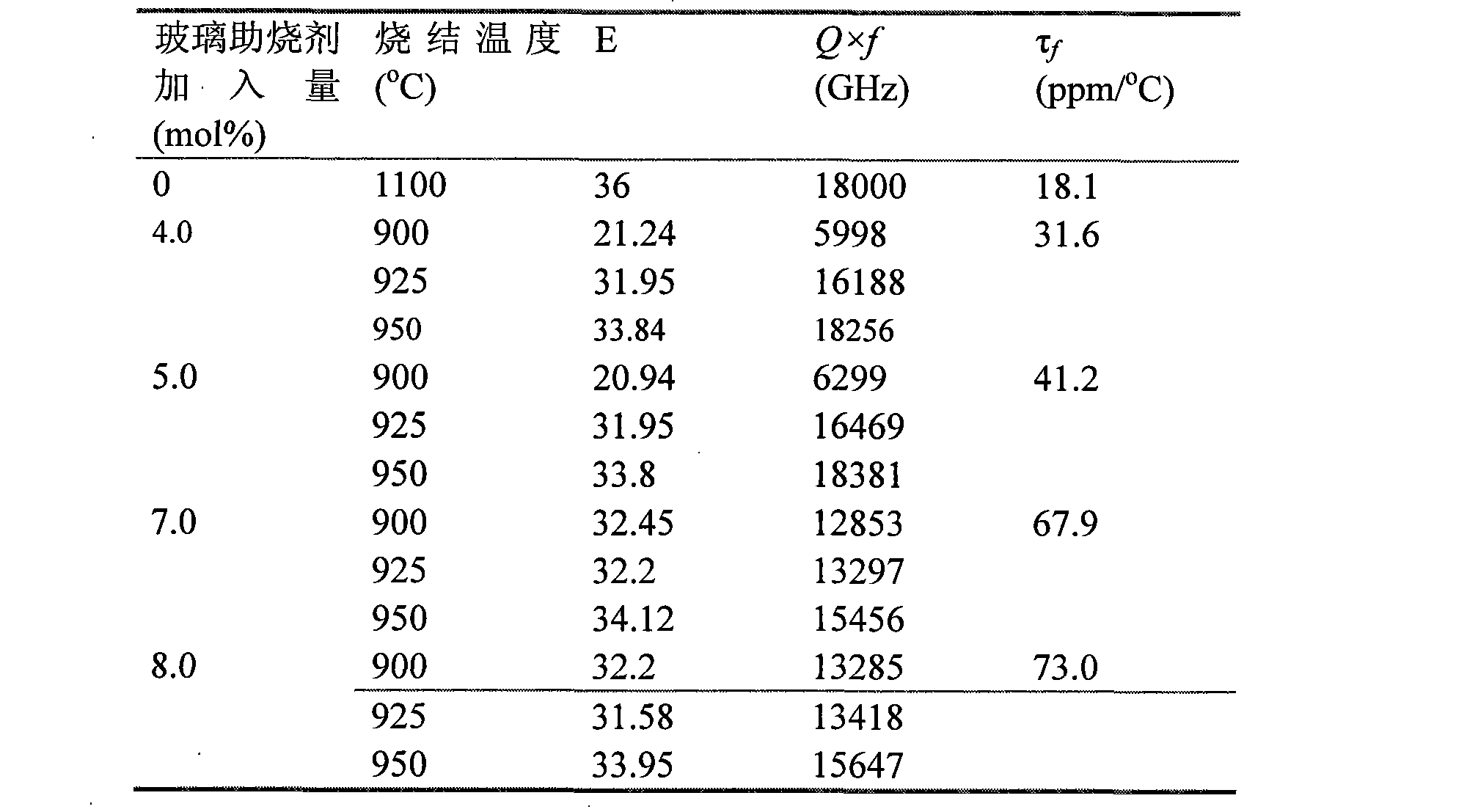

Embodiment 1

[0034] 1) Prepare the raw material, make the raw material BaCO 3 , ZnO, TiO 2 The molar ratio of Q and Q is BaCO 3 :ZnO:TiO 2 : Q=1: 0.5: 4.3: (0.04~0.08); wherein Q is a glass sintering aid, and the glass sintering aid is the analytically pure Li 2 O, ZnO, and B 2 o 3 Moore Billy 2 O:ZnO:B 2 o 3 = 1:2:7 mixing, after ball milling, heat preservation at 1100°C for 0.5h and then quenching; the BaCO 3 and ZnO are of analytically pure grade, the TiO 2 For chemically pure grade.

[0035] 2) The prepared BaCO 3 , ZnO and TiO 2 Mix the raw materials, put them into a nylon tank, add alcohol, wherein the volume ratio of raw materials and alcohol is 1:4, ball mill for 4 hours, take it out, dry it at 100°C, pass through a 200-mesh sieve, and press it into a block;

[0036] 3) The pressed block is pre-fired at 1000°C for 4 hours to obtain the main powder sintered block;

[0037] 4) Pulverize the above-mentioned synthesized main powder into powder, add glass sintering aid acco...

Embodiment 2

[0044] 1) Prepare the raw material, make the raw material BaCO 3 , ZnO, TiO 2 The molar ratio of Q and Q is BaCO 3 :ZnO:TiO 2 : Q==1: 0.5: 4.3: (0.02~0.05) preparation; Wherein Q is glass sintering aid, and glass sintering aid is the Li of analysis pure 2 O, ZnO, and B 2 o 3 Moore Billy 2 O:ZnO:B 2 o 3 = 3: 2: 5 mixed, after ball milling, heat preservation at 1100°C for 0.5h and then quenching; the BaCO 3 and ZnO are of analytically pure grade, the TiO 2 For chemically pure grade.

[0045] 2) The prepared BaCO 3 , ZnO and TiO 2 Mix the raw materials, put them into a nylon tank, add industrial alcohol, wherein the volume ratio of raw materials and industrial alcohol is 1:5, ball mill for 5 hours, take it out, dry it at 200°C, pass through a 200-mesh sieve, and press it into a block;

[0046] 3) The compressed block is pre-fired at 1100°C for 4 hours to obtain the main powder sintered block;

[0047] 4) Pulverize the above-mentioned synthesized main powder body into...

Embodiment 3

[0055] 1) Prepare the raw material, make the raw material BaCO 3 , ZnO, TiO 2 The molar ratio of Q and Q is BaCO 3 :ZnO:TiO 2 : Q=1: 0.2: 4.3: (0.02~0.05); wherein Q is a glass sintering aid, and the glass sintering aid is the analytically pure Li 2 O, ZnO, and B 2 o 3 Moore Billy 2 O:ZnO:B 2 o 3 = 3: 2: 5 mixed, after ball milling, heat preservation at 1100°C for 0.5h and then quenching; the BaCO 3 and ZnO are of analytically pure grade, the TiO 2 For chemically pure grade.

[0056] 2) The prepared BaCO 3 , ZnO and TiO 2 Mix the raw materials, put them into a nylon tank, add alcohol, wherein the volume ratio of raw materials and alcohol is 1:4, ball mill for 4 hours, take it out, dry it at 200°C, pass through a 200-mesh sieve, and press it into a block;

[0057] 3) The pressed block is pre-fired at 1000°C for 4 hours to obtain the main powder sintered block;

[0058] 4) Crush the above-mentioned synthesized main powder into powder, add glass sintering aid accordi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com