Low-temperature sintering silver electrode slurry

A low-temperature sintering, silver electrode technology, applied in conductive materials, conductive materials, circuits, etc., can solve the problem that electrode paste is not suitable for sensitive resistance, and achieve good silver crystallization and stable electrical properties, good compactness, and small particle size distribution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

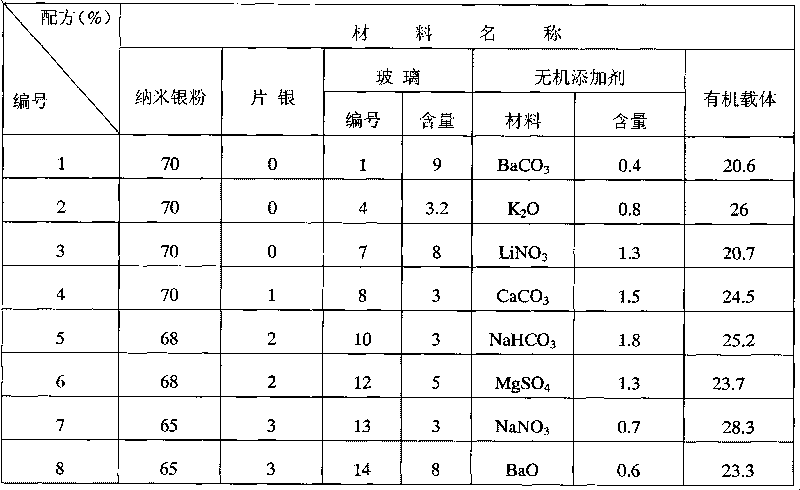

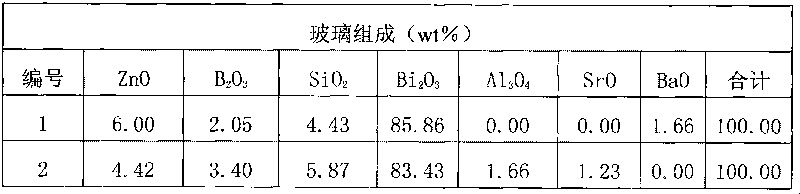

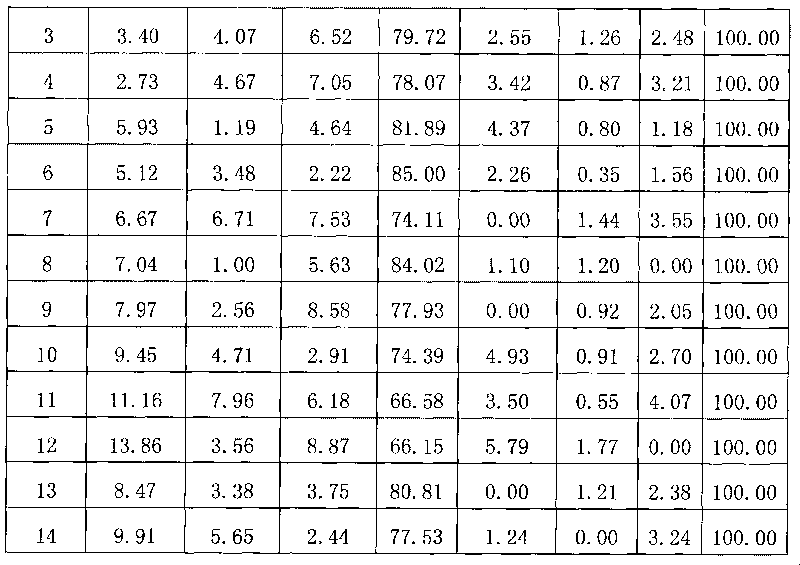

[0014] A low-temperature sintered silver electrode paste, the formula of which is in accordance with No. 1-8 formulas in Table 1. After components fine-tuning, wet ball milling, sand milling, drying and other processes, a main material with good dispersibility and uniform composition can be obtained. The polymer resin described in the formula is one or more of ethyl cellulose, hydrogenated rosin resin, polyethylene, polyurethane resin; the solvent is one or more of alcohol solvent, aromatic hydrocarbon solvent or ester solvent Several kinds; the composition of the organic carrier in the silver electrode paste by weight is 0.5-4wt% of polymer resin and 10-20wt% of alcohol solvent. The particle size of the nano silver powder is below 200nm, and the particle size of the flake silver powder is 15 μm. The glass formula selected in the formula is shown in 1-14 of Table 2. After mixing all materials evenly, use a three-roll mill to fully grind and roll to meet certain fineness and vi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com