Pulsating heat pipe heat exchanger with lyophilic coatings

A technology of pulsating heat pipes and heat exchangers, which is applied to indirect heat exchangers, lighting and heating equipment, etc., can solve the problems of the working fluid and the inner wall of the pipeline without adopting enhanced heat exchange methods, so as to improve the temperature distribution characteristics and improve the heat transfer rate. The effect of high heat coefficient and heat transfer coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] With the rapid development of the electronics industry, the physical size of electronic components is getting smaller and smaller, but their heat generation is getting bigger and bigger, which leads to an increasing heat flux density for heat dissipation. Therefore, traditional heat dissipation methods are facing huge challenge. This embodiment is mainly used to illustrate the application of a pulsating heat pipe with a lyophilic coating proposed by the present invention in the field of electronic heat dissipation.

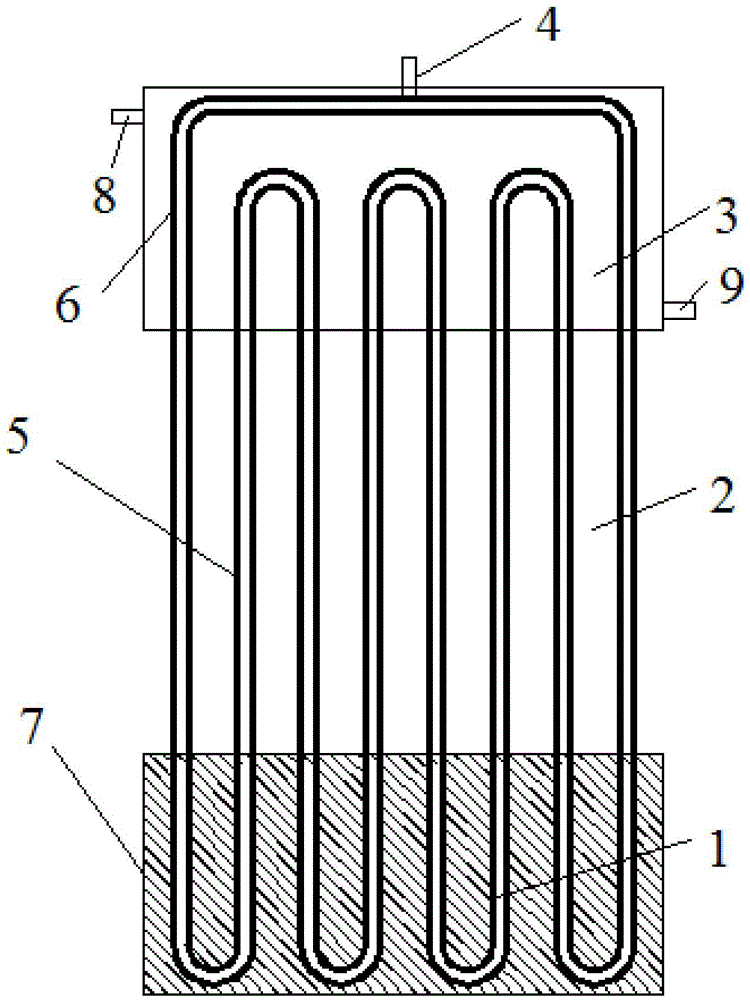

[0034] as attached figure 2 As shown, a pulsating heat pipe with a lyophilic coating proposed by the present invention is connected to the heat sink plate 7 of the heat-generating electronic component through heat-conducting silicone grease. The calorific value of the electronic components is transferred to the evaporation section 1 of the pulsating heat pipe pipe 6 through the heat-conducting silicone grease and the heat sink plate 7. The adjacent gas o...

Embodiment 2

[0045] Due to the inevitable waste of energy in industrial production, most of this energy is lost in the form of heat energy. Recovering this part of energy is of great significance for improving the energy utilization efficiency of industrial production. This embodiment is mainly used to illustrate the application of a pulsating heat pipe with a lyophilic coating inside in the field of industrial waste heat recovery proposed by the present invention.

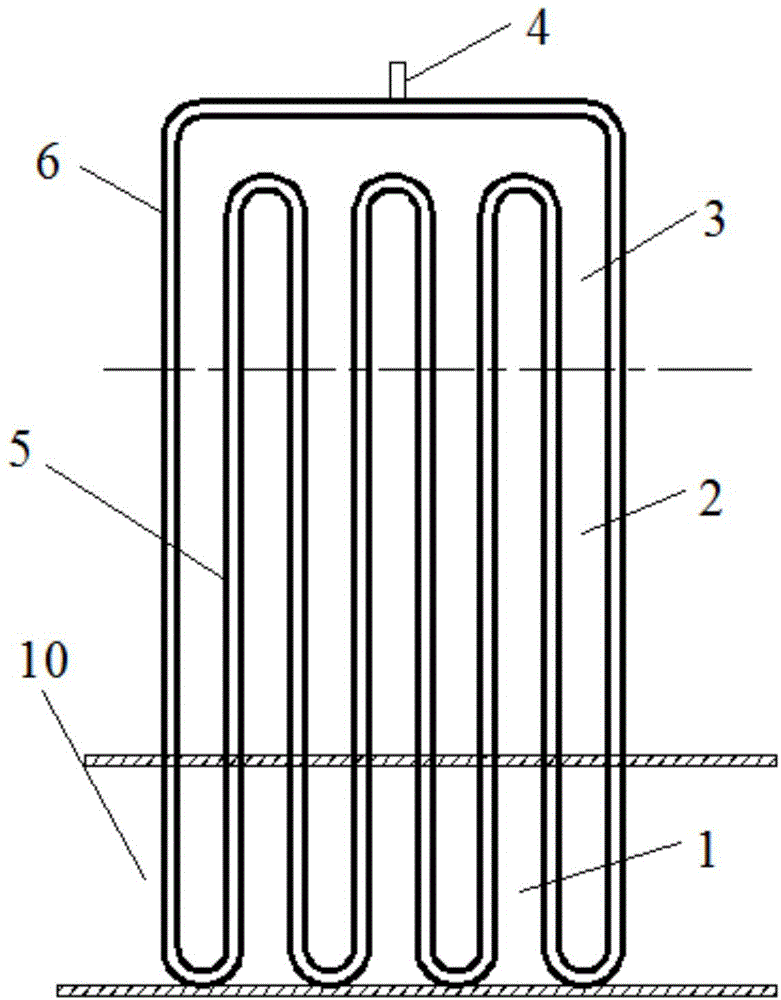

[0046] as attached image 3 As shown, the evaporating section 1 of a pulsating heat pipe with a lyophilic coating inside proposed by the present invention is placed in an industrial waste heat pipeline 10, while the condensing section 3 is arranged in an environment where we need to utilize waste heat. Since the pipe diameter of the pulsating heat pipe is small, when the inside of the pulsating heat pipe is filled with working fluid, a state of alternate existence of gas plugs and liquid plugs will be formed inside the pulsati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com