Method for monitoring Tg of polymer-based composite material by using carbon nano-paper sensor

A composite material and carbon nano-paper technology, which is applied in the analysis of materials, material inspection products, and material analysis by electromagnetic means. Tg monitoring of matrix composite materials, etc., to achieve the effect of real-time online monitoring, low cost, and simple measurement process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0021] The method for monitoring the Tg of the polymer-based composite material by the carbon nanopaper sensor of this embodiment is performed according to the following steps:

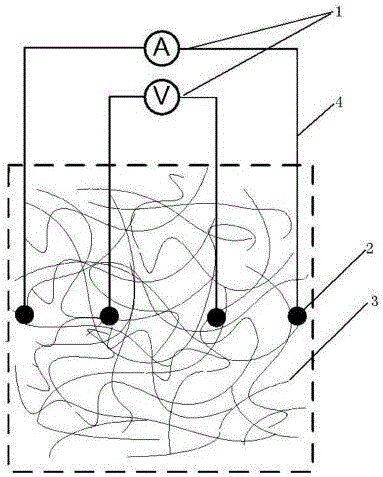

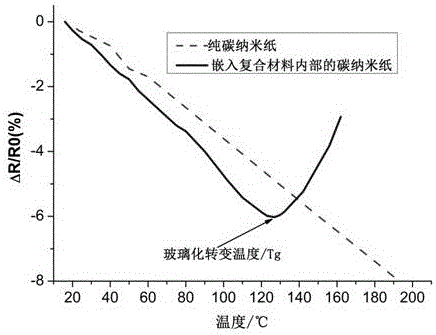

[0022] (1) Such as figure 1 As shown, four copper wires 4 are fixed on the surface of the rectangular carbon nano paper 3 to form a carbon nano paper sensor. The sensor is embedded in the prepreg of the polymer-based composite material to be monitored, and the polymer-based composite material is prepreg The standard curing process of the material is cured and molded to obtain a polymer-based composite material. The polymer-based composite material in this embodiment is glass fiber / epoxy resin. The specific curing process is in accordance with [0] 16 Laminating method, placed on a mold coated with a release agent, where the carbon nano paper sensor and fiber grating are placed between the 8th and 9th layers of the composite material, and the mold with prepreg is encapsulated in a vacuum bag , Placed in an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com